PLA Plus Wine Red 1kg – Premium Filament for 3D Printing

PLA Plus Wine Red is a high-quality 3D printing filament with a deep, elegant wine-red shade that exudes luxury and sophistication. This filament combines the excellent mechanical properties of PLA Plus with a rich color, perfect for projects where both appearance and performance matter. With its enhanced strength and glossy surface finish, Wine Red is the perfect choice for designers, artists, and technical enthusiasts alike.

Key Benefits

- Rich wine-red color: An elegant and striking shade that gives your prints a premium look – ideal for design and visually demanding projects.

- Improved strength and toughness: PLA Plus offers greater impact resistance and deformation resistance compared to standard PLA, resulting in more durable prints.

- Excellent printability: Easy to print with minimal warping and great bed adhesion – suitable for both beginners and professionals.

- Eco-friendly material: Made from biodegradable, non-toxic materials, ensuring safe printing for both home and professional use.

Applications

- Decorative and interior design elements: Create luxurious accessories, vases, sculptures, or details with an exclusive wine-red finish.

- Fashion accessories and jewelry: Perfect for stylish bracelets, pendants, and ornaments that stand out with their deep color and shine.

- Artistic and gift items: Ideal for figurines, sculptures, gift decorations, or collectible pieces.

- Functional prototypes: Great for prototypes that need to be not only strong but also aesthetically representative.

- Premium advertising and presentation models: Suitable for company logos, signage, and display models that should look professional and luxurious.

Ideal For

- Designers and artists looking for a bold and elegant color.

- Products where both aesthetics and mechanical strength are important.

- Users who prefer eco-friendly and high-quality materials.

- Projects requiring a combination of durability, precision, and luxurious appearance.

PLA Plus Wine Red brings elegance, reliability, and distinctive aesthetics to 3D printing. With its deep wine-red color and enhanced properties, it is perfect for all projects where design meets performance – from artistic creations to professional showcases.

Specifications

| Colour | Wine Red |

| Weight | 1 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

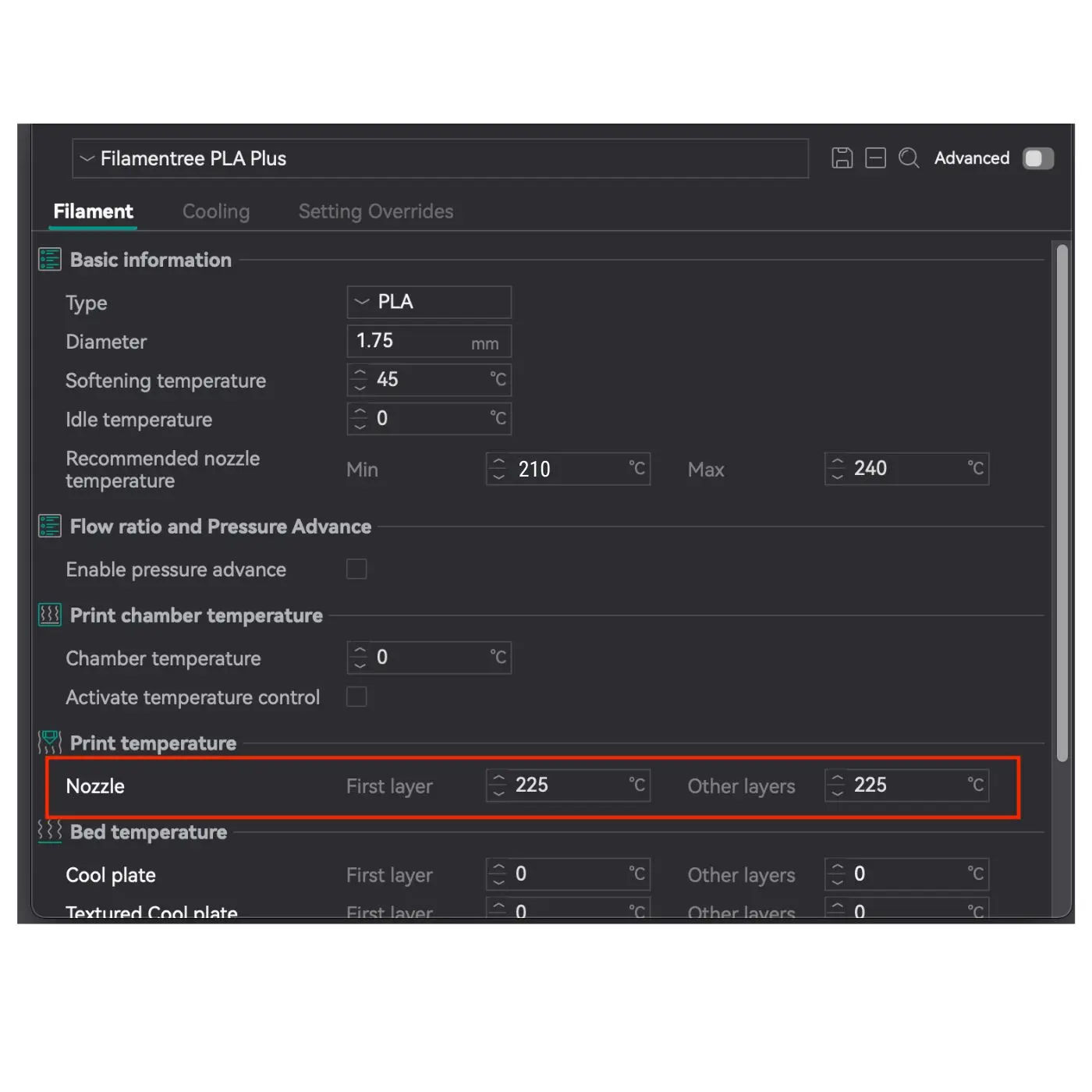

| Printing Temperature | 210-240°C |

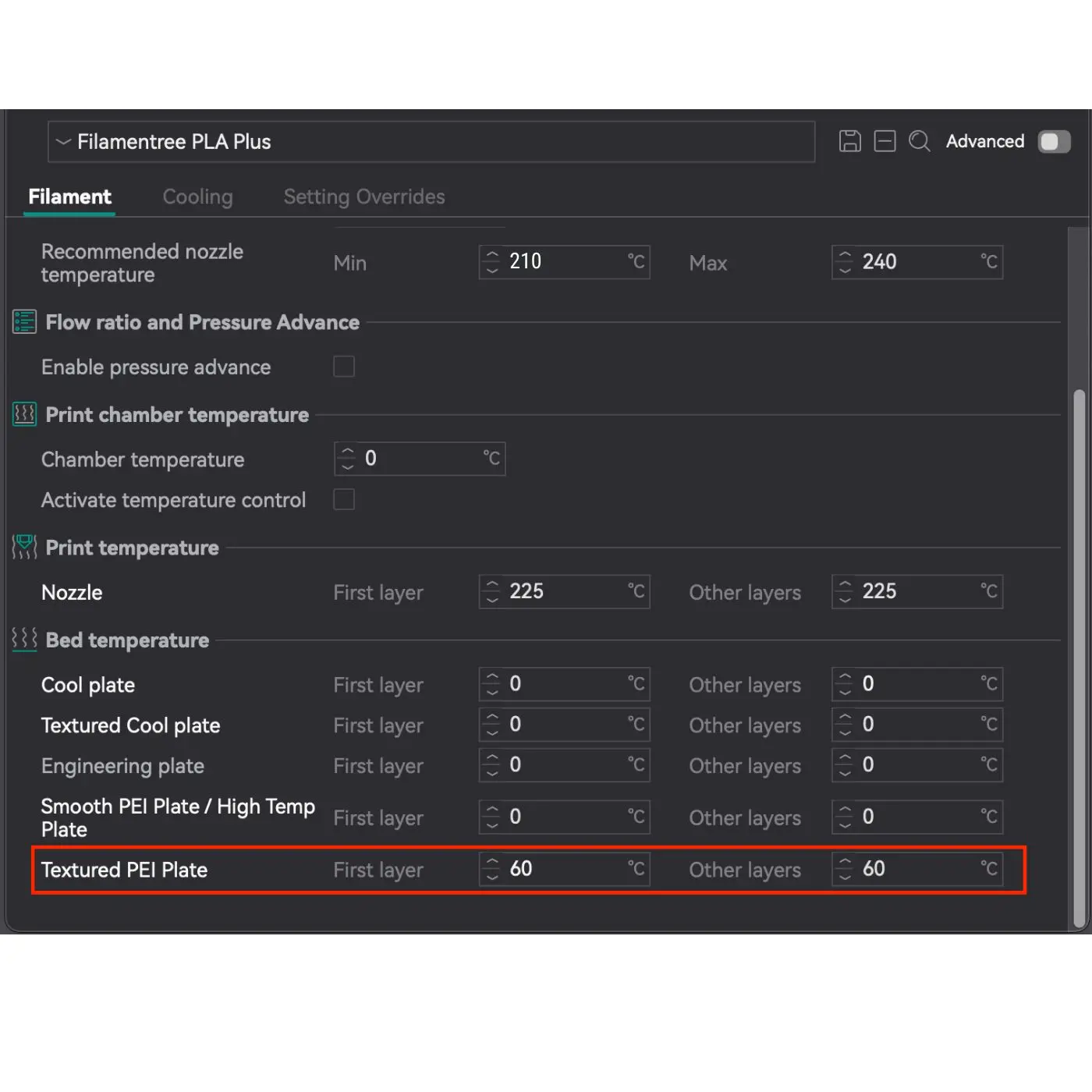

| Bed Temperature | 0–60°C (prints well without a heated bed) |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 50°C |

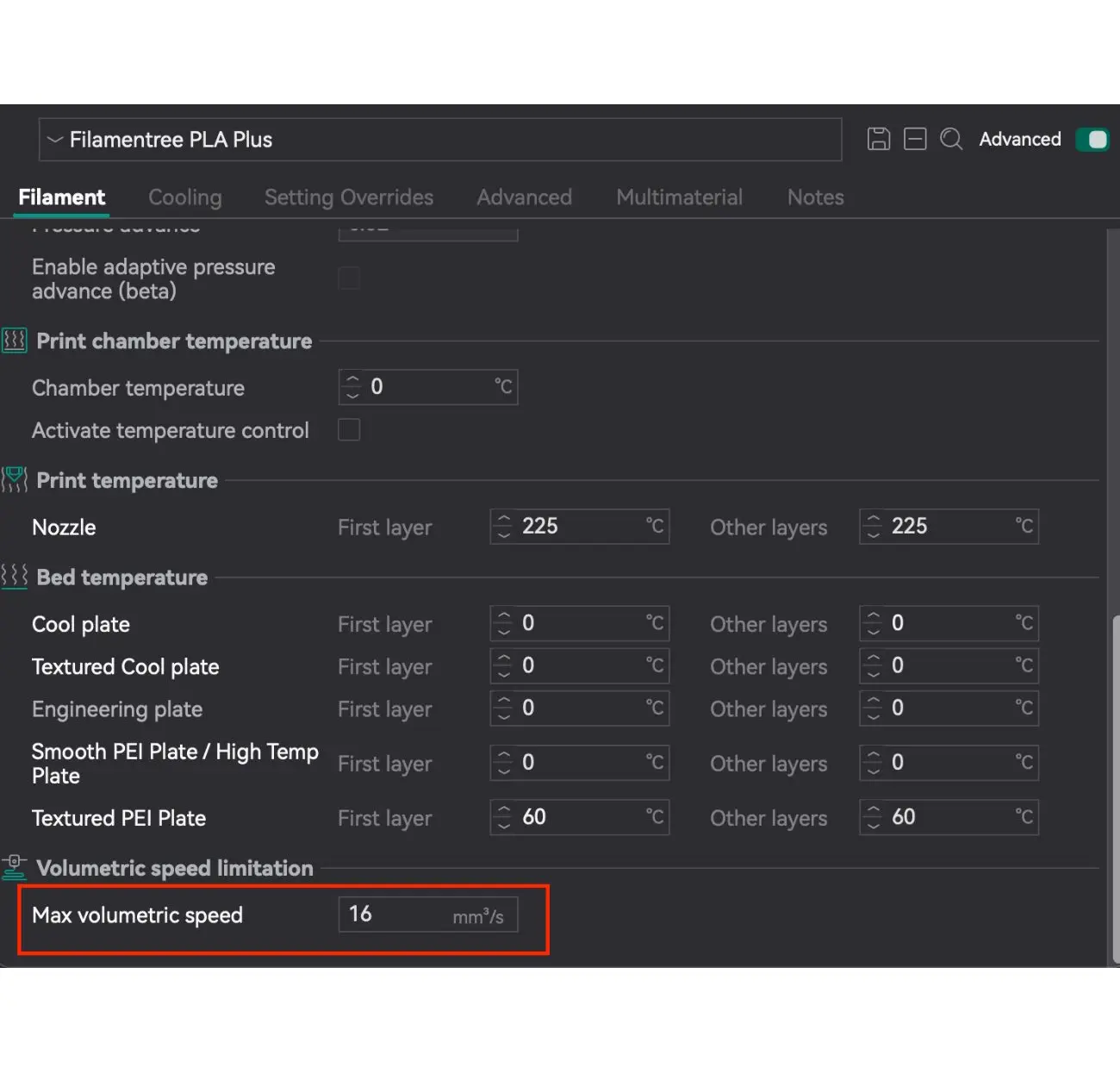

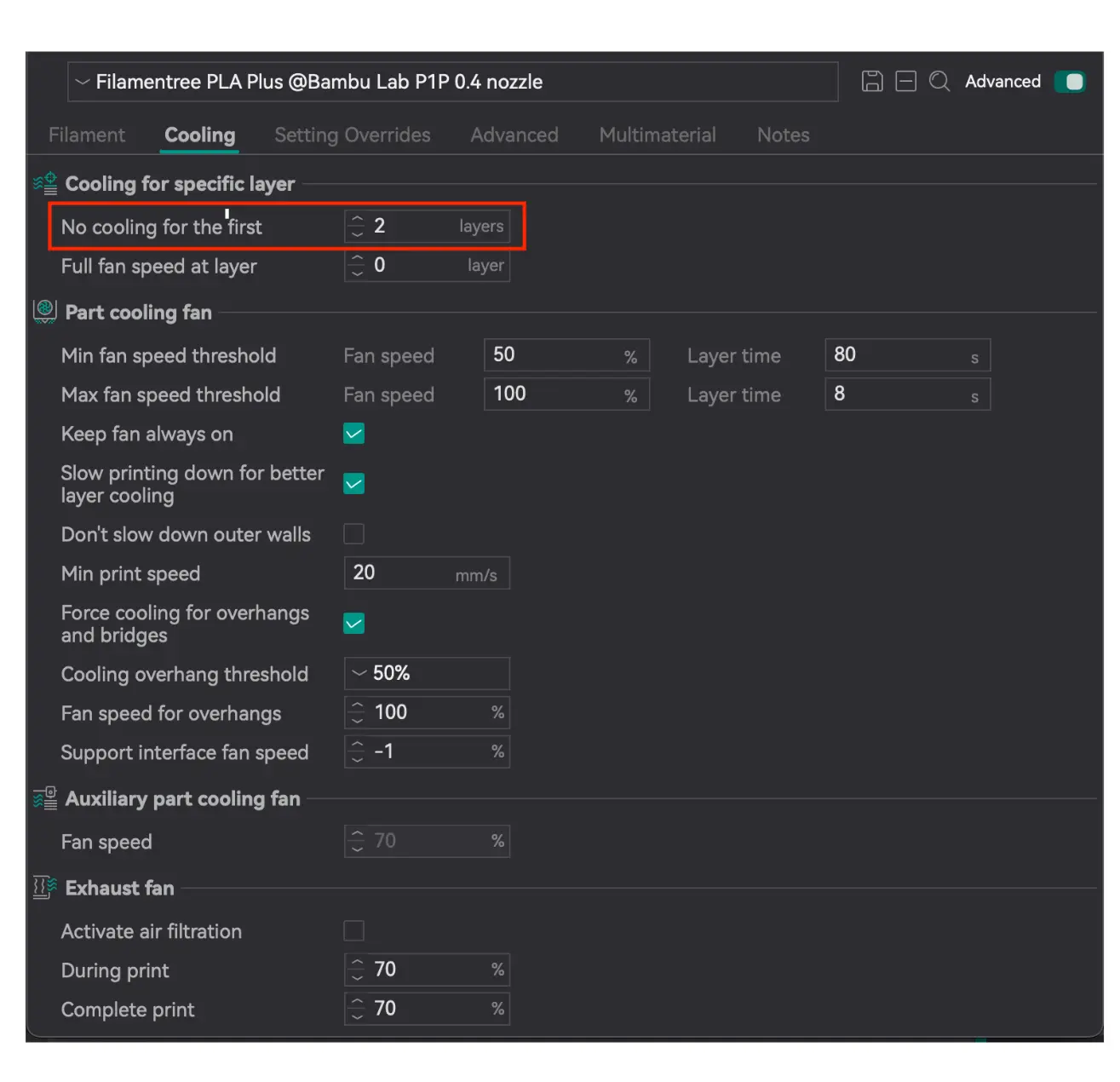

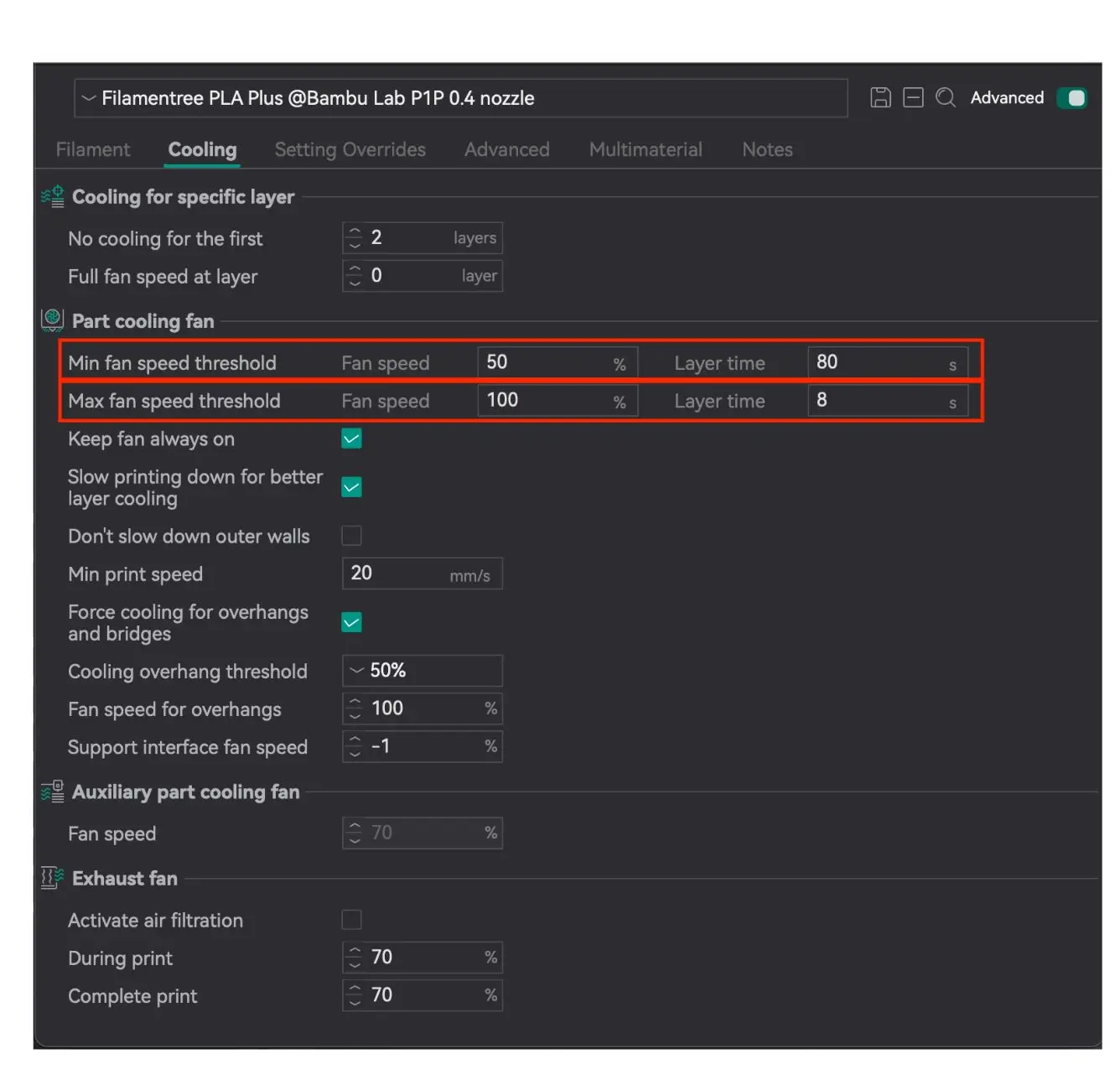

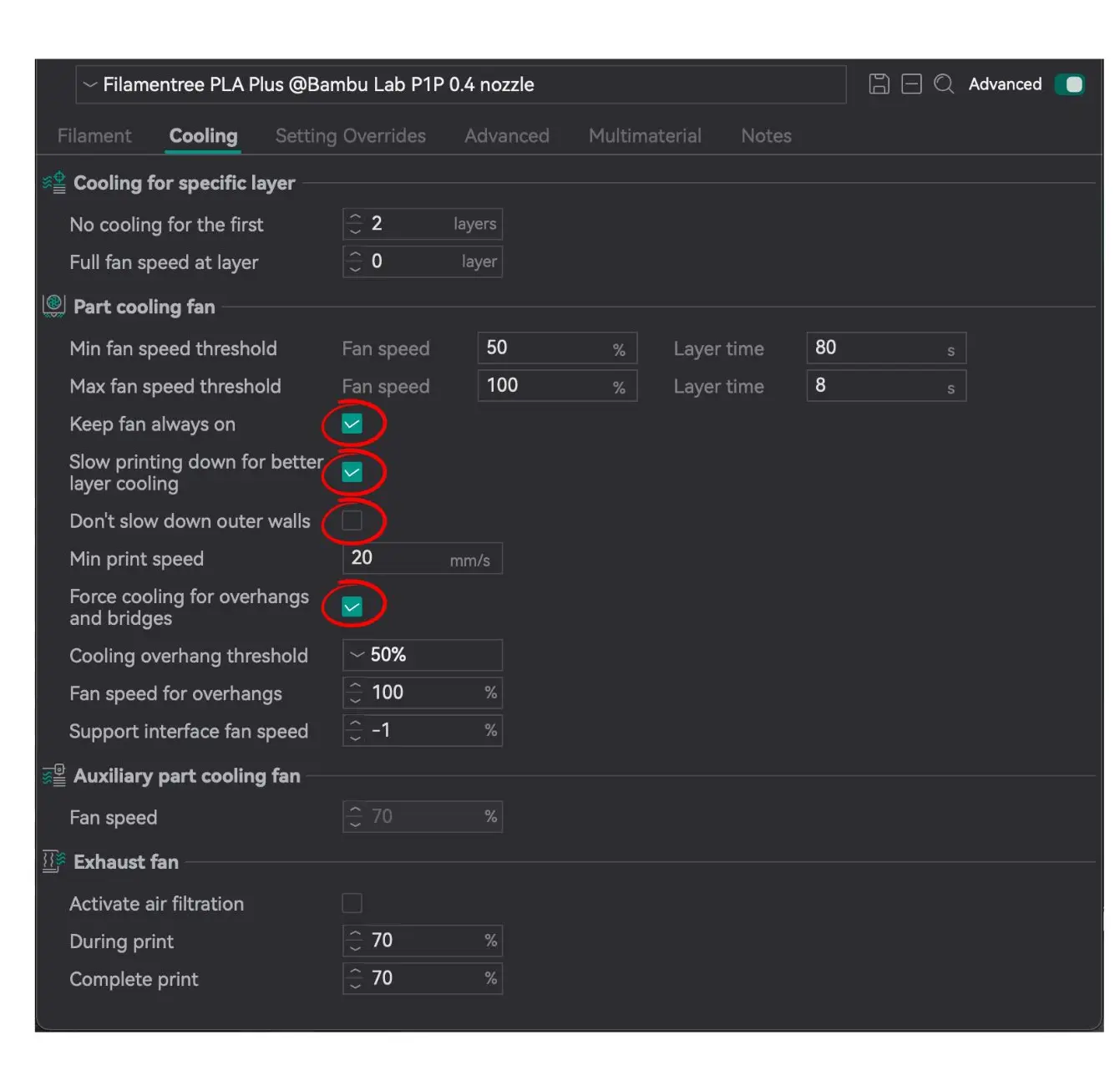

PLA Plus (PLA+) – Print Settings

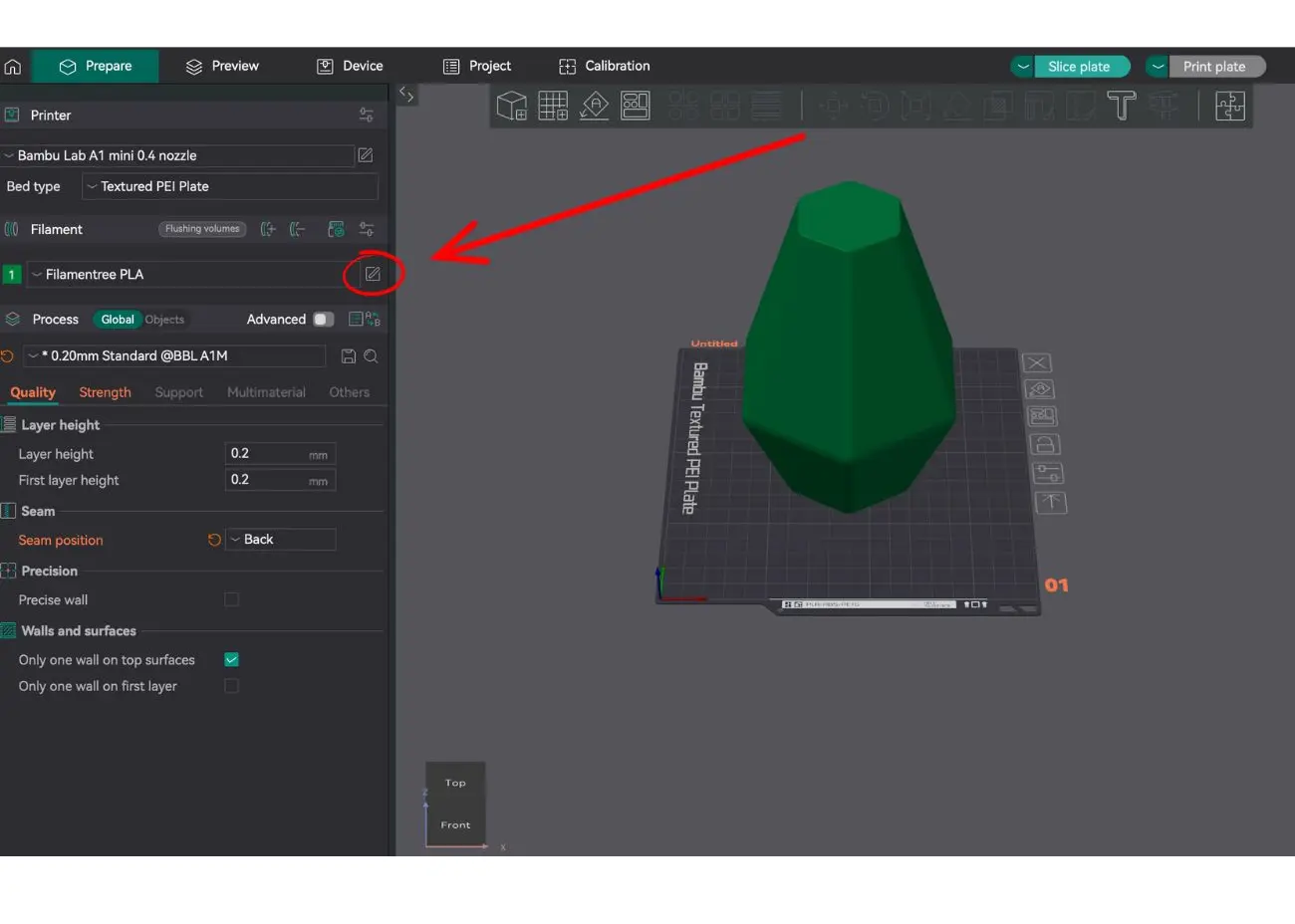

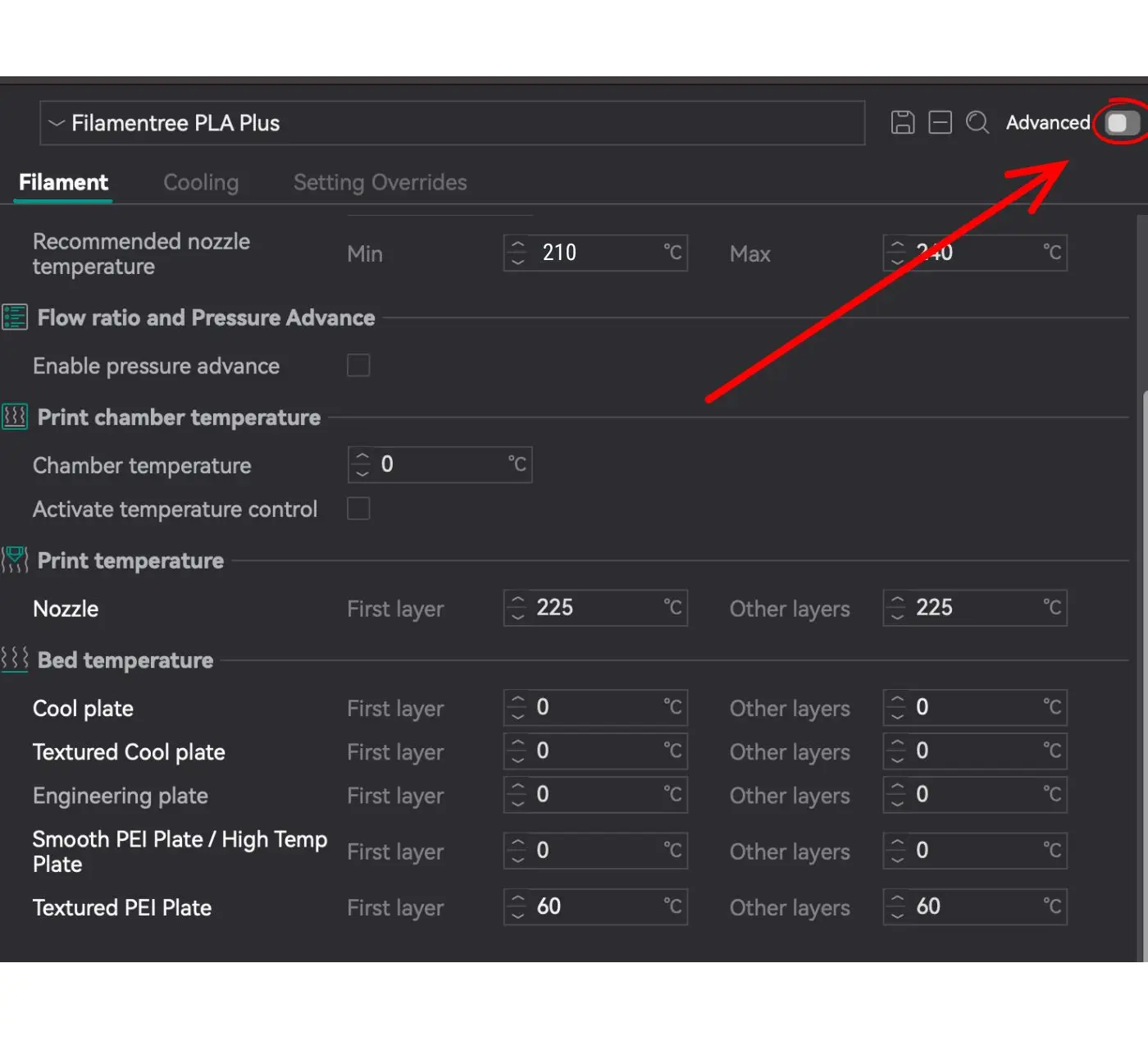

PLA Plus (PLA+) is an improved version of classic PLA, offering higher strength, better flexibility, and increased durability. To achieve the best printing results, it is essential to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

Using the correct printing parameters for PLA Plus is critically important for achieving high-quality results. PLA Plus, as an improved version of standard PLA, requires precise settings to optimize its properties. Following the recommended settings allows you to fully leverage the benefits of PLA Plus, ensuring strong, aesthetically appealing, and durable prints.