PLA Plus Olive Green 1kg – Prémiový filament pre 3D tlač

PLA Plus Olive Green je prémiový 3D tlačový filament s elegantným olivovo zeleným odtieňom, ktorý vyniká prirodzeným, tlmeným vzhľadom a moderným charakterom. Tento odtieň je ideálny pre dizajnové, technické aj ekologicky zamerané projekty. Vďaka vysokej pevnosti, jednoduchému spracovaniu a matnému povrchu prináša dokonalú rovnováhu medzi funkčnosťou a estetikou.

Hlavné výhody

- Elegantná olivovo zelená farba: Jemný, prírodný odtieň, ktorý dodáva výtlačkom moderný, ekologický a profesionálny vzhľad.

- Vylepšená pevnosť a húževnatosť: PLA Plus ponúka vyššiu odolnosť voči nárazom a prasknutiu ako štandardné PLA, čo zaručuje dlhšiu životnosť výtlačkov.

- Jednoduché spracovanie: Skvelá priľnavosť, nízke riziko deformácií a výborné vrstvenie zabezpečujú čistý a presný výsledok pri každej tlači.

- Ekologický materiál: Vyrobený z biologicky odbúrateľných, netoxických surovín – šetrný k životnému prostrediu aj používateľovi.

Aplikácie

- Dekoratívne predmety: Ideálny na výrobu dizajnových doplnkov, bytových dekorácií a umeleckých objektov s prírodným vzhľadom.

- Architektonické a prototypové modely: Skvelý pre modely, ktoré kombinujú presnosť s elegantným, tlmeným vzhľadom.

- Funkčné výtlačky: Vhodný pre držiaky, puzdrá, technické komponenty či doplnky s požiadavkou na pevnosť a estetiku.

- Outdoorové a ekologické projekty: Výborne sa hodí pre produkty s prírodnou tematikou alebo do zelených projektov.

- Umelecké a remeselné práce: Pre figúrky, modely a kreatívne diela s jemným, moderným farebným akcentom.

Ideálne pre

- Dizajnérov a tvorcov hľadajúcich prírodnú, elegantnú farebnú paletu.

- Projekty spájajúce technickú presnosť s estetickým vzhľadom.

- Používateľov, ktorí uprednostňujú ekologické a spoľahlivé materiály.

- Výtlačky určené pre moderné, minimalistické alebo prírodné prostredie.

PLA Plus Olive Green prináša do 3D tlače štýlovú kombináciu pevnosti, spoľahlivosti a prírodného dizajnu. Ideálny pre všetkých, ktorí hľadajú filament s moderným vzhľadom, vysokou kvalitou a ekologickým charakterom.

| Colour | Olive Green |

| Weight | 1 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

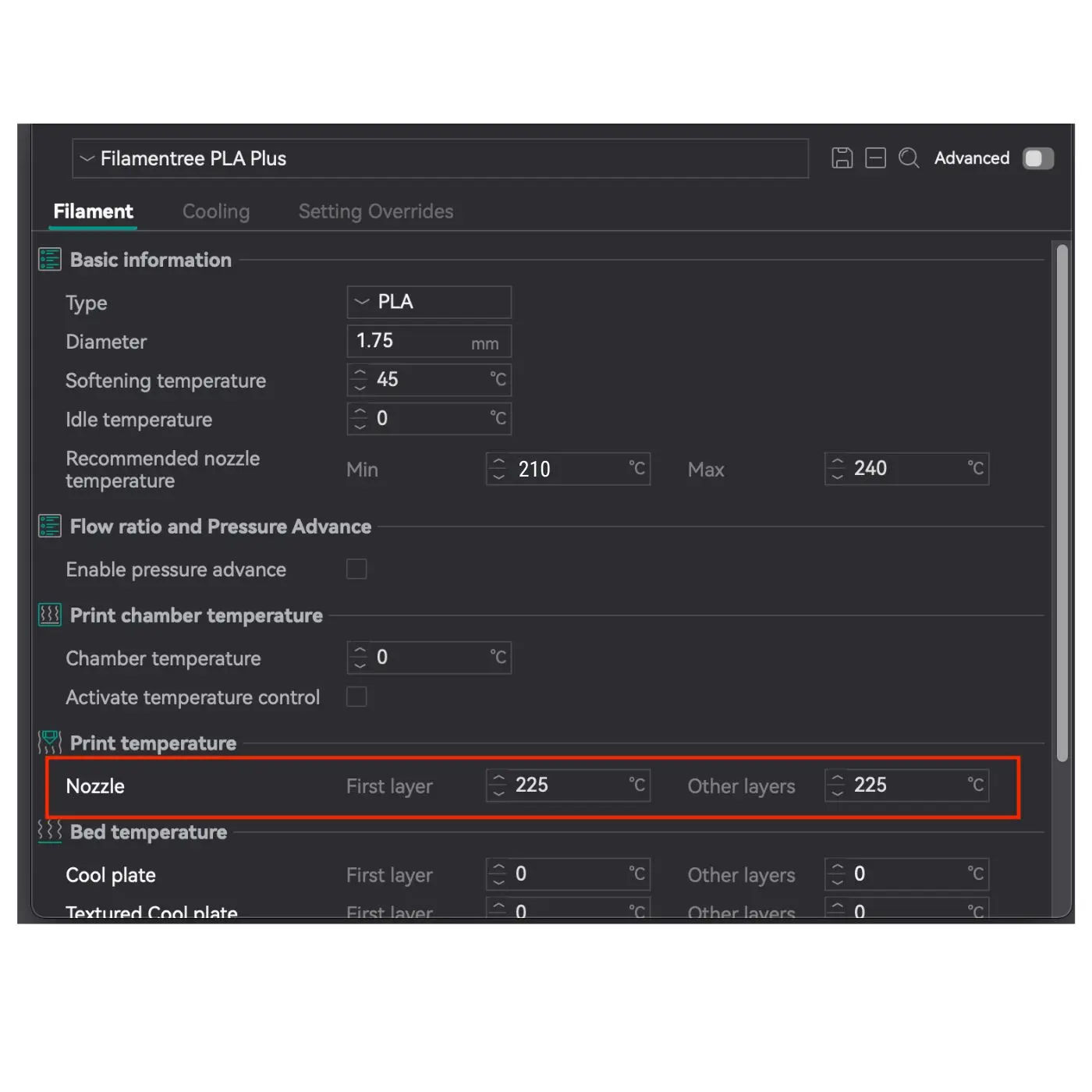

| Printing Temperature | 210-240°C |

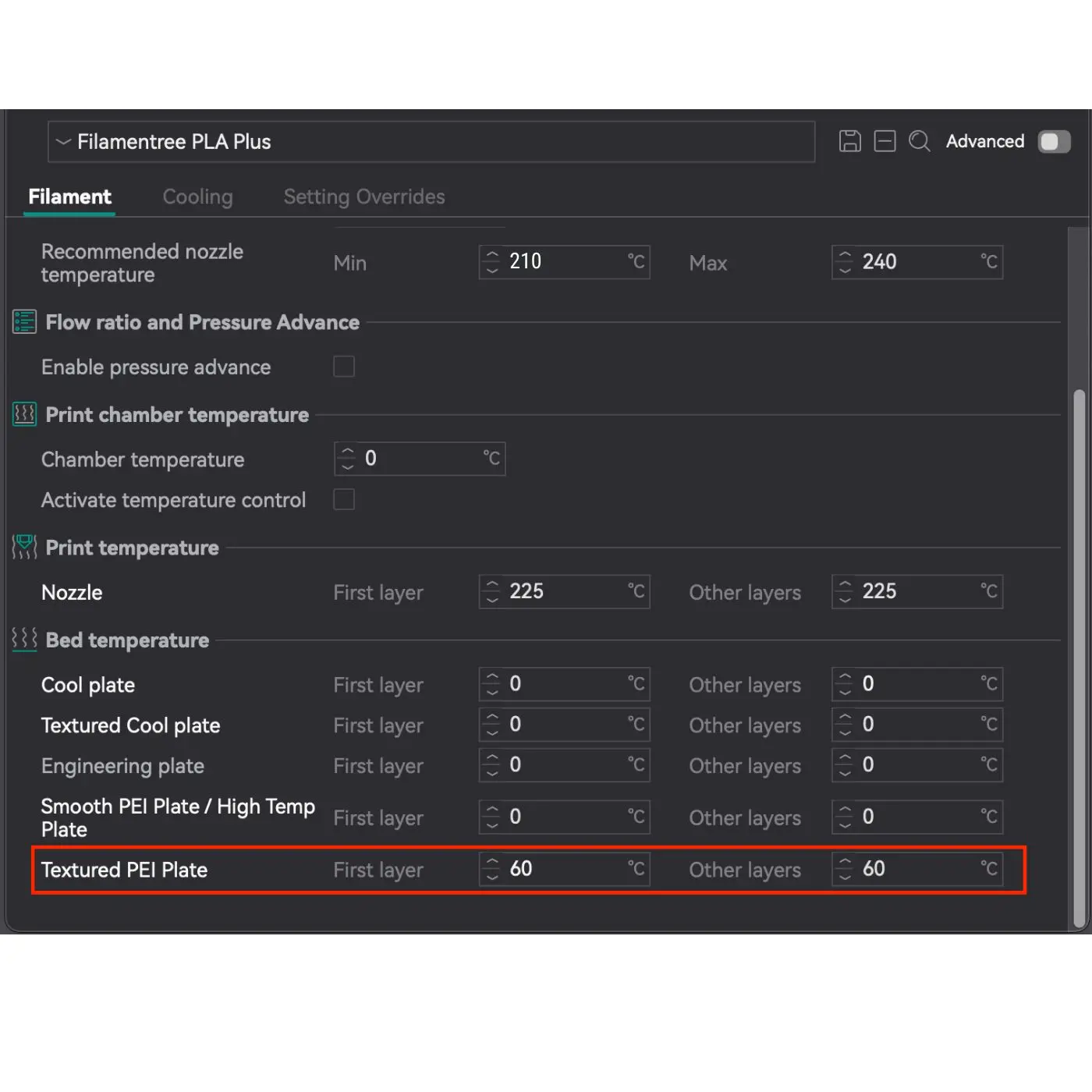

| Bed Temperature | 0–60°C (prints well without a heated bed) |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 50°C |

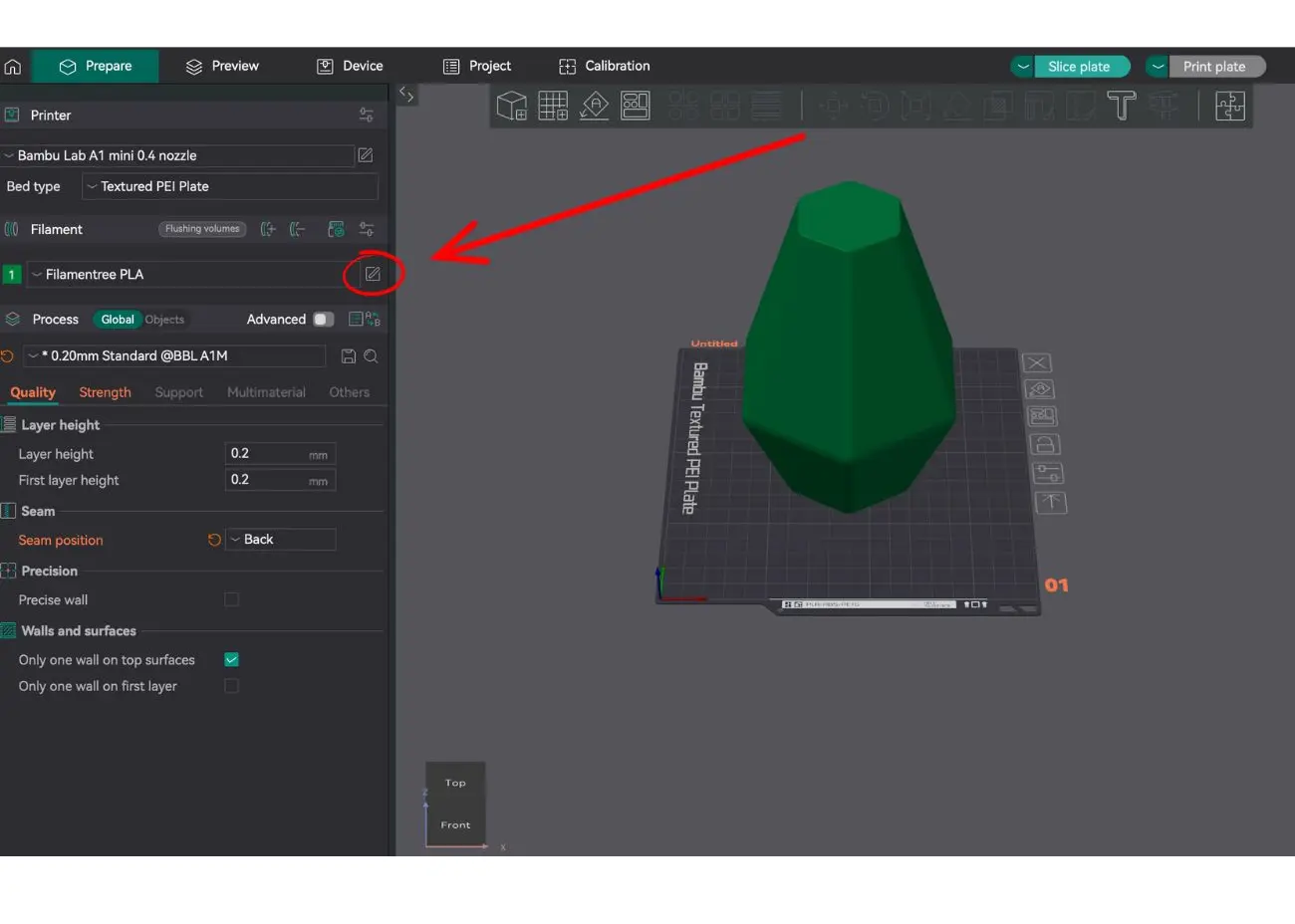

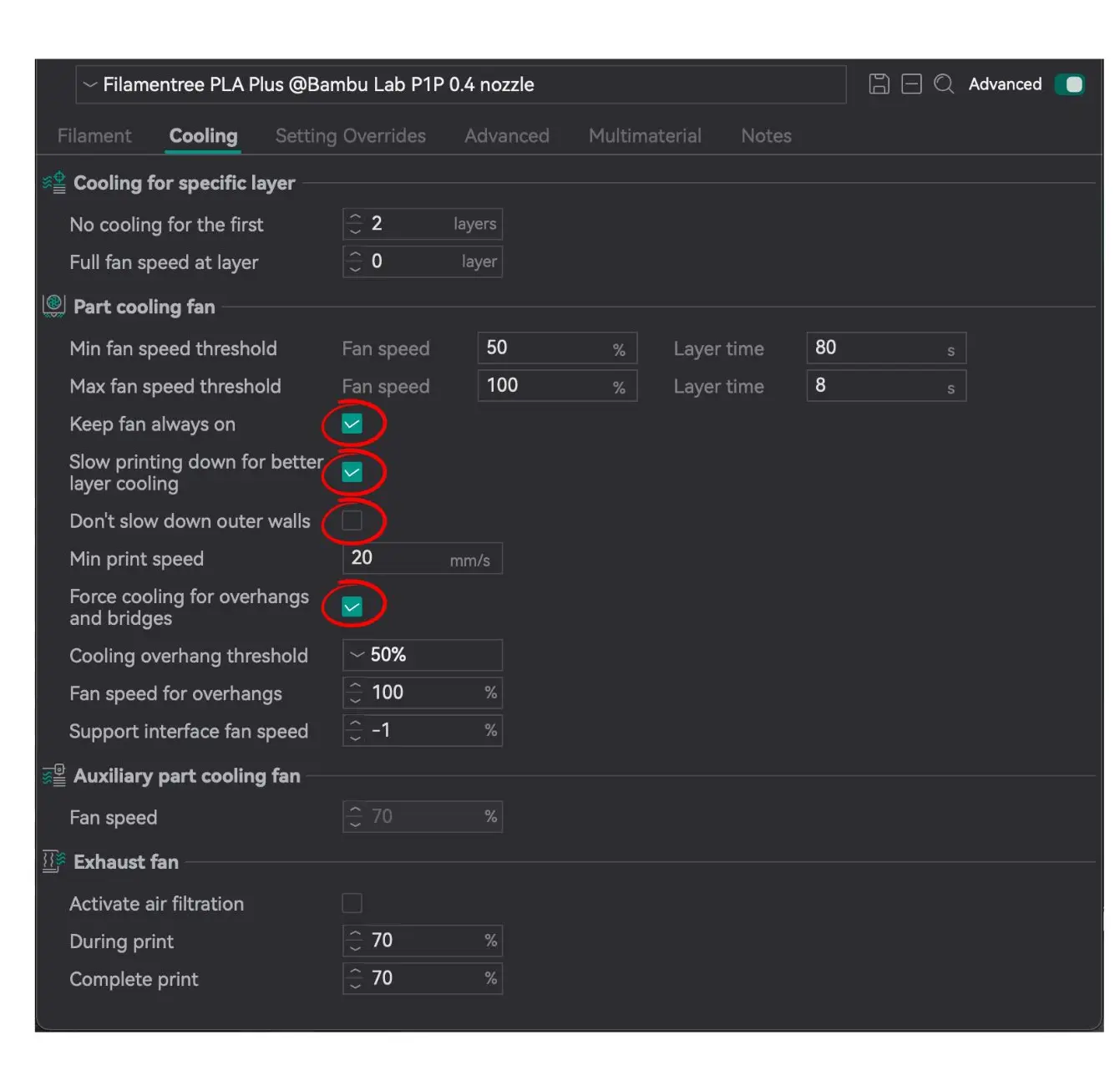

PLA Plus (PLA+) – Print Settings

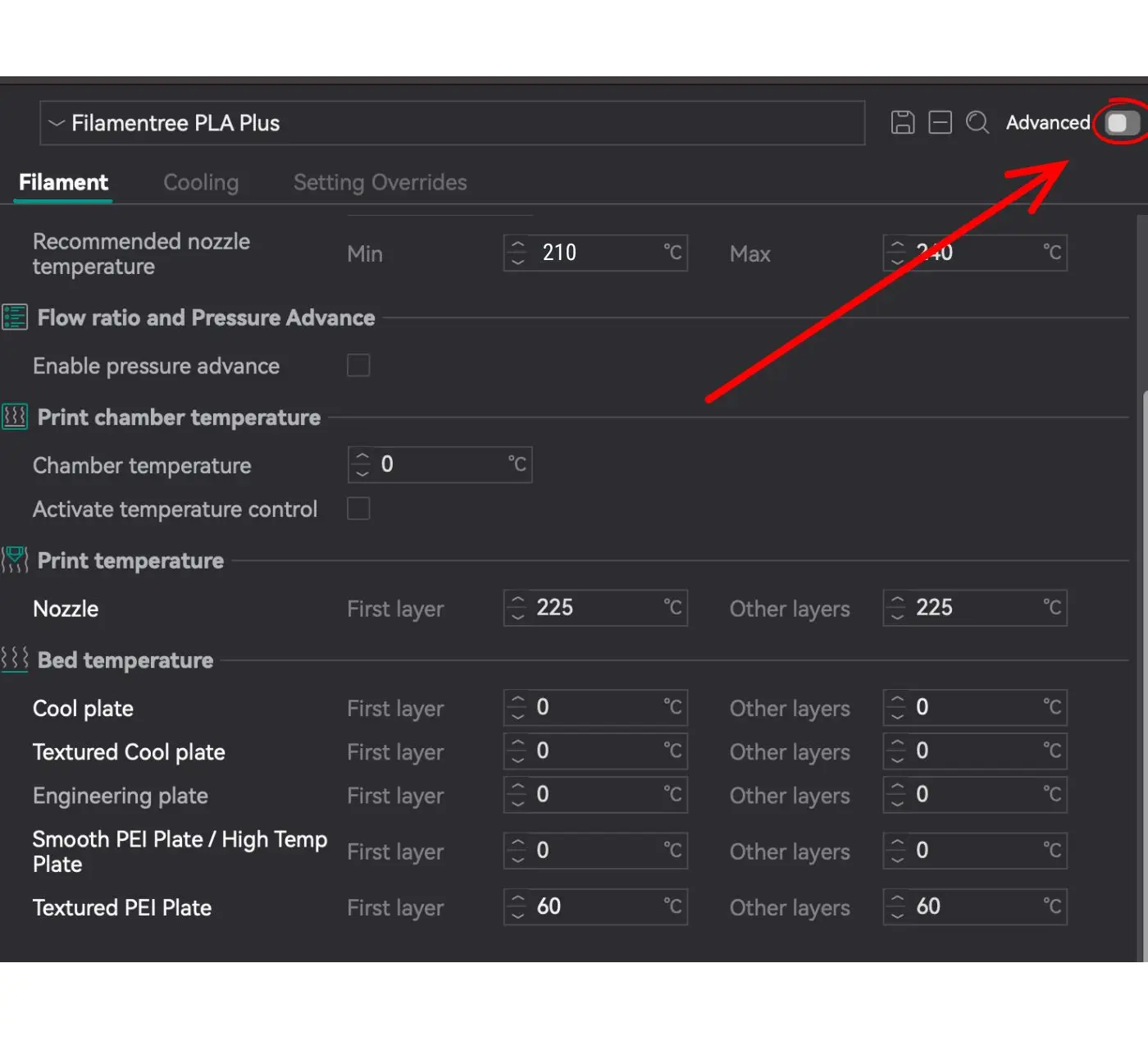

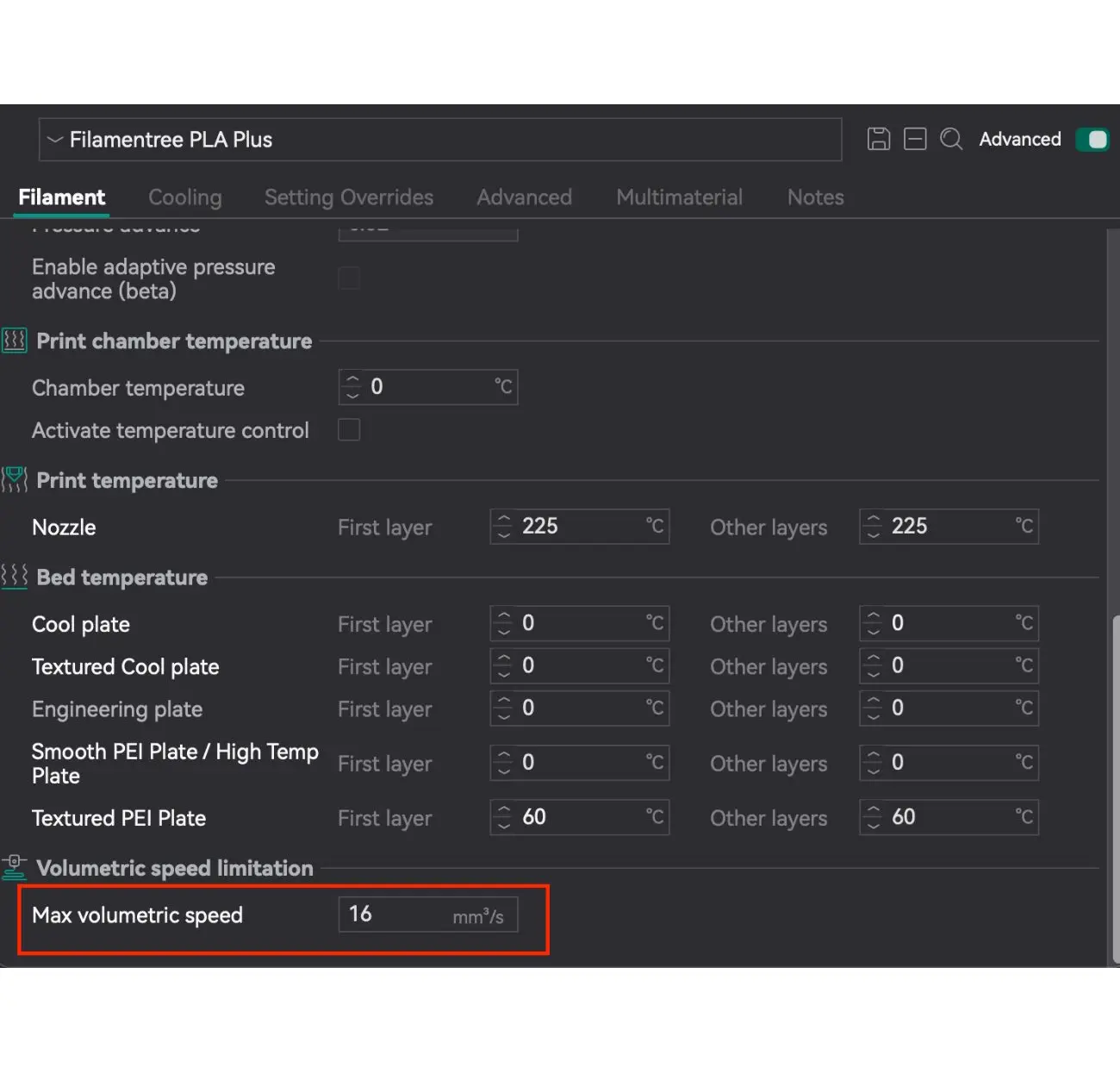

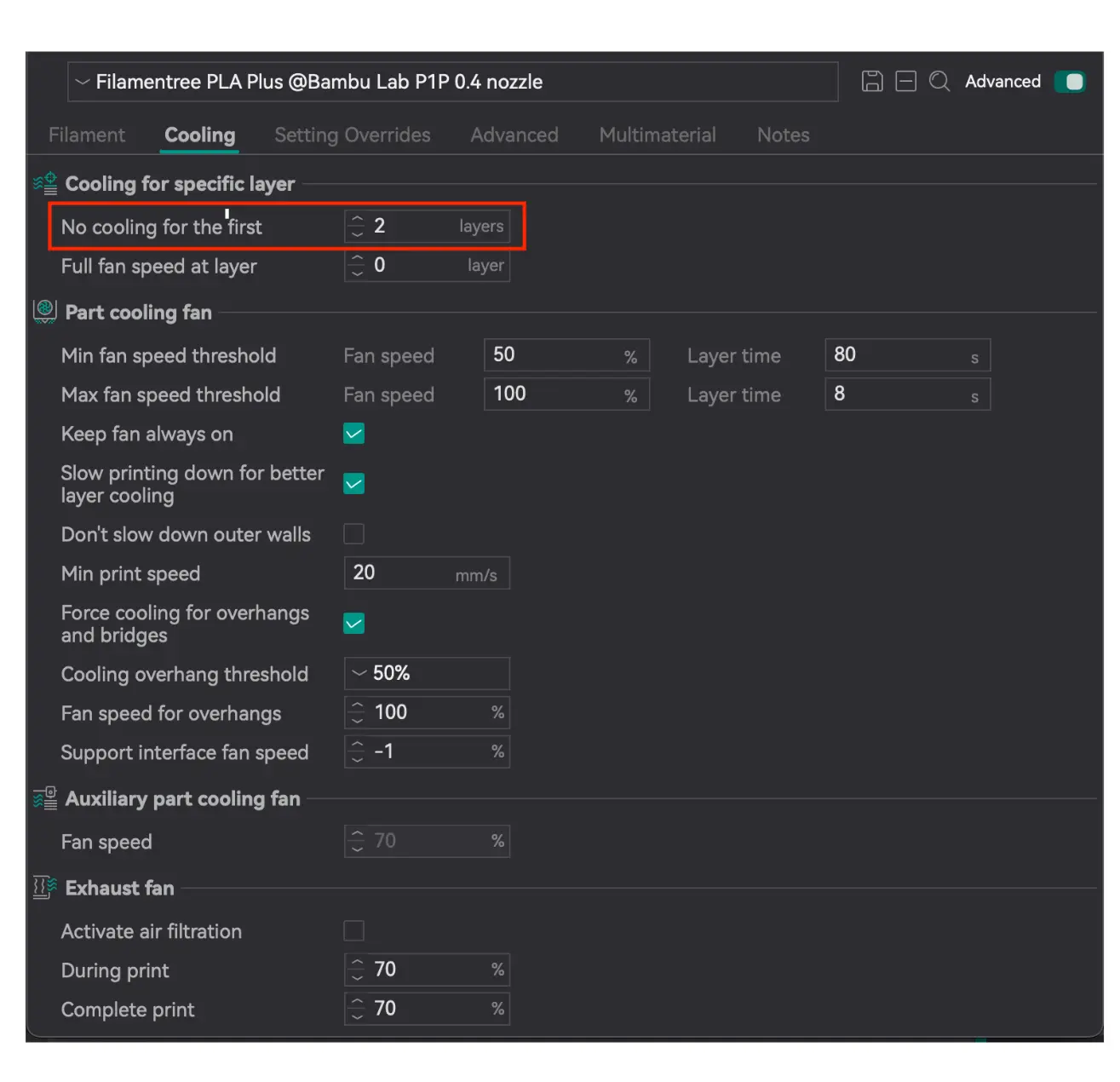

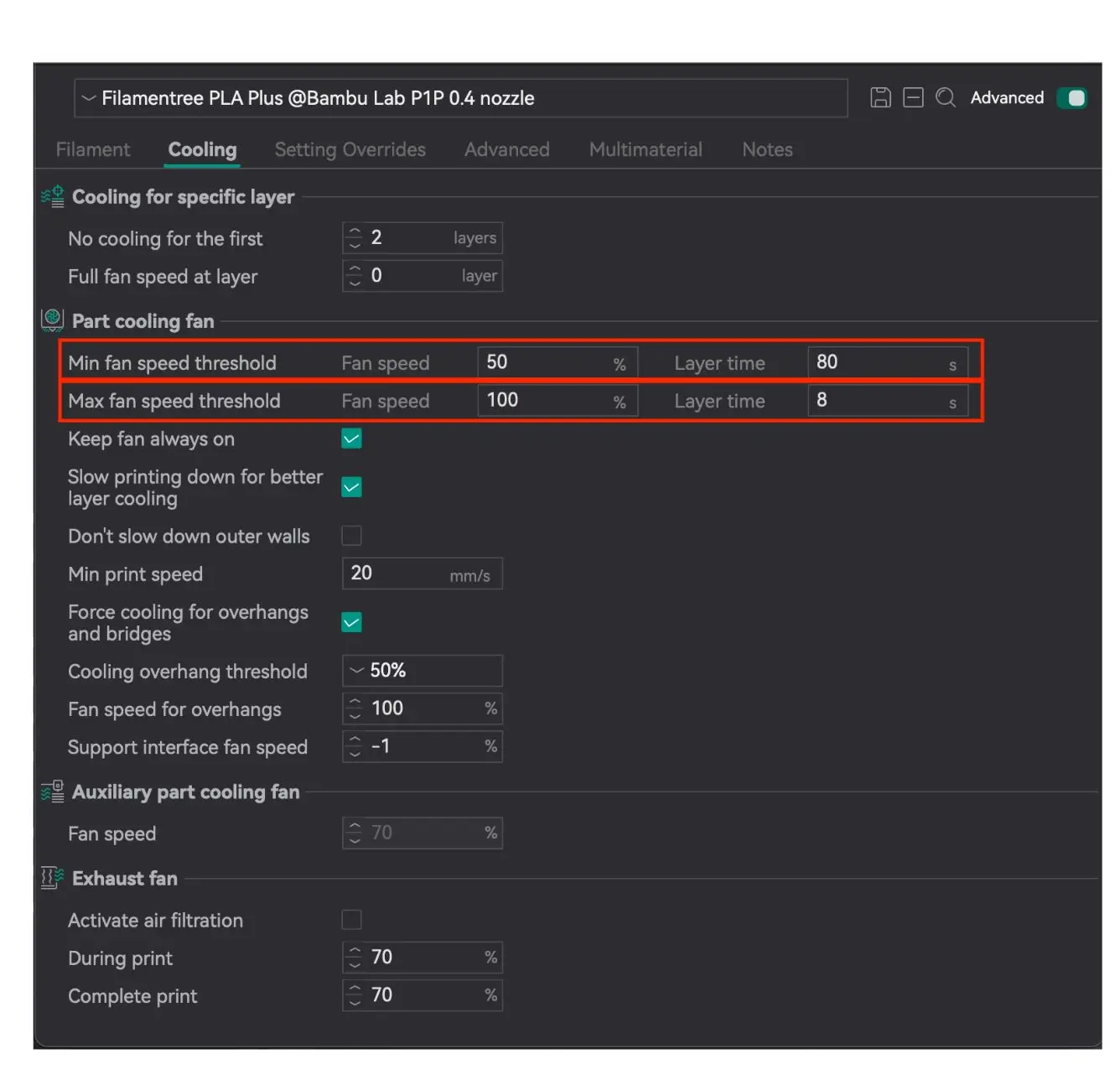

PLA Plus (PLA+) is an improved version of classic PLA, offering higher strength, better flexibility, and increased durability. To achieve the best printing results, it is essential to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

Using the correct printing parameters for PLA Plus is critically important for achieving high-quality results. PLA Plus, as an improved version of standard PLA, requires precise settings to optimize its properties. Following the recommended settings allows you to fully leverage the benefits of PLA Plus, ensuring strong, aesthetically appealing, and durable prints.