PLA Plus Neon Yellow 1kg – Premium 3D Printing Filament

PLA Plus Neon Yellow is a high-visibility, fluorescent filament designed for projects that demand attention, bold aesthetics, and superior durability. This electrifying neon yellow shade ensures your prints stand out, making it ideal for safety applications, eye-catching designs, and functional parts that require both strength and striking color. With the enhanced mechanical properties of PLA Plus, this filament guarantees long-lasting, high-quality results with a vibrant glow.

Key Benefits

- Ultra-Bright Neon Yellow: The intense neon yellow hue provides maximum visibility, making it perfect for safety markings, high-impact signage, and designs that need to stand out.

- Enhanced Strength & Durability: PLA Plus offers superior impact resistance and toughness compared to standard PLA, ensuring strong and reliable prints for everyday use.

- Effortless Printing: Excellent bed adhesion, minimal warping, and broad compatibility with most 3D printers provide a smooth and hassle-free printing experience for users of all skill levels.

- Eco-Friendly & Safe: Made from biodegradable, non-toxic materials, supporting sustainable 3D printing without compromising performance or color intensity.

Applications

- Safety & Industrial Markings: Print warning signs, emergency labels, and high-visibility markers for enhanced workplace and outdoor safety.

- Sports & Outdoor Gear: Create durable accessories for cycling, hiking, and outdoor activities that require high visibility.

- Advertising & Promotional Materials: Design eye-catching marketing displays, event decorations, and product prototypes that grab attention instantly.

- Functional Prototypes & Mechanical Parts: Ideal for durable brackets, casings, and ergonomic tools where a bright aesthetic adds value.

- Creative & Artistic Projects: Perfect for neon-themed sculptures, gaming accessories, and futuristic cosplay props.

Ideal For

- Projects that demand high visibility and vibrant color.

- Functional prints requiring strength, flexibility, and impact resistance.

- Branding, advertising, and promotional applications where standing out is key.

- Eco-conscious creators who prioritize sustainability without compromising performance.

PLA Plus Neon Yellow is the ultimate filament for ensuring your prints shine with unmatched brightness, strength, and reliability. Whether for safety, innovation, or creative expression, this filament guarantees results that demand attention.

| Colour | Neon Yellow |

| Weight | 1 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

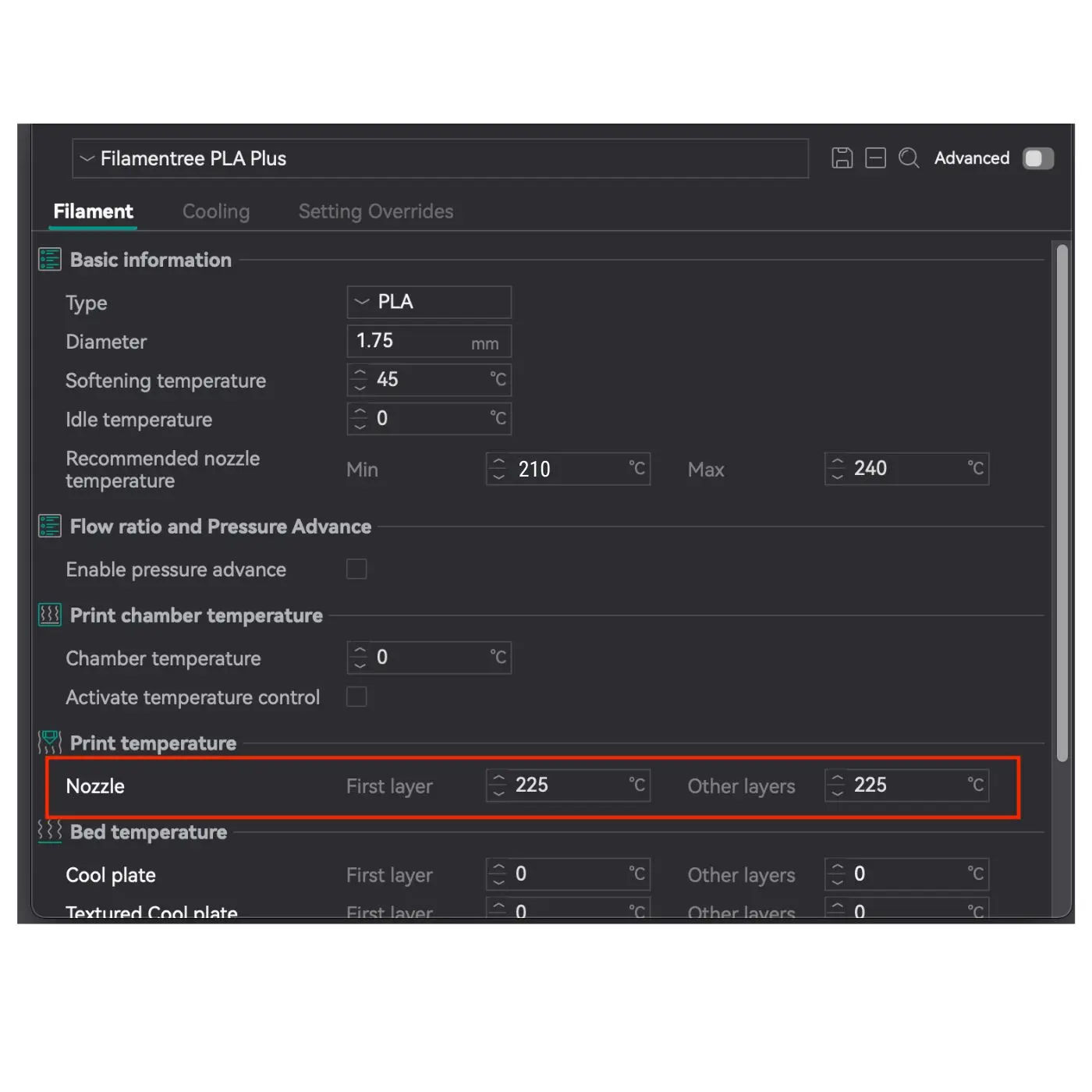

| Printing Temperature | 210-240°C |

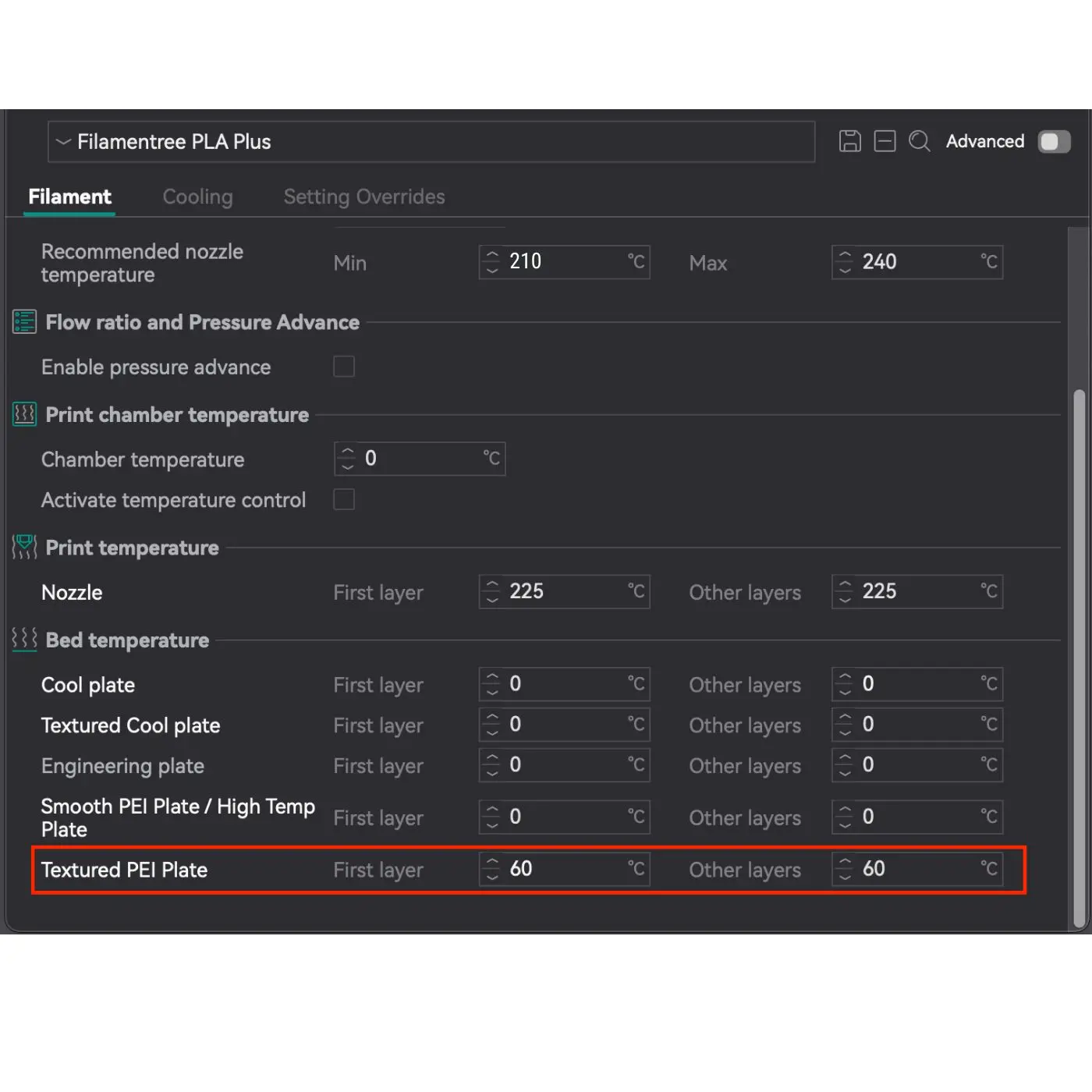

| Bed Temperature | 0–60°C (prints well without a heated bed) |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 50°C |

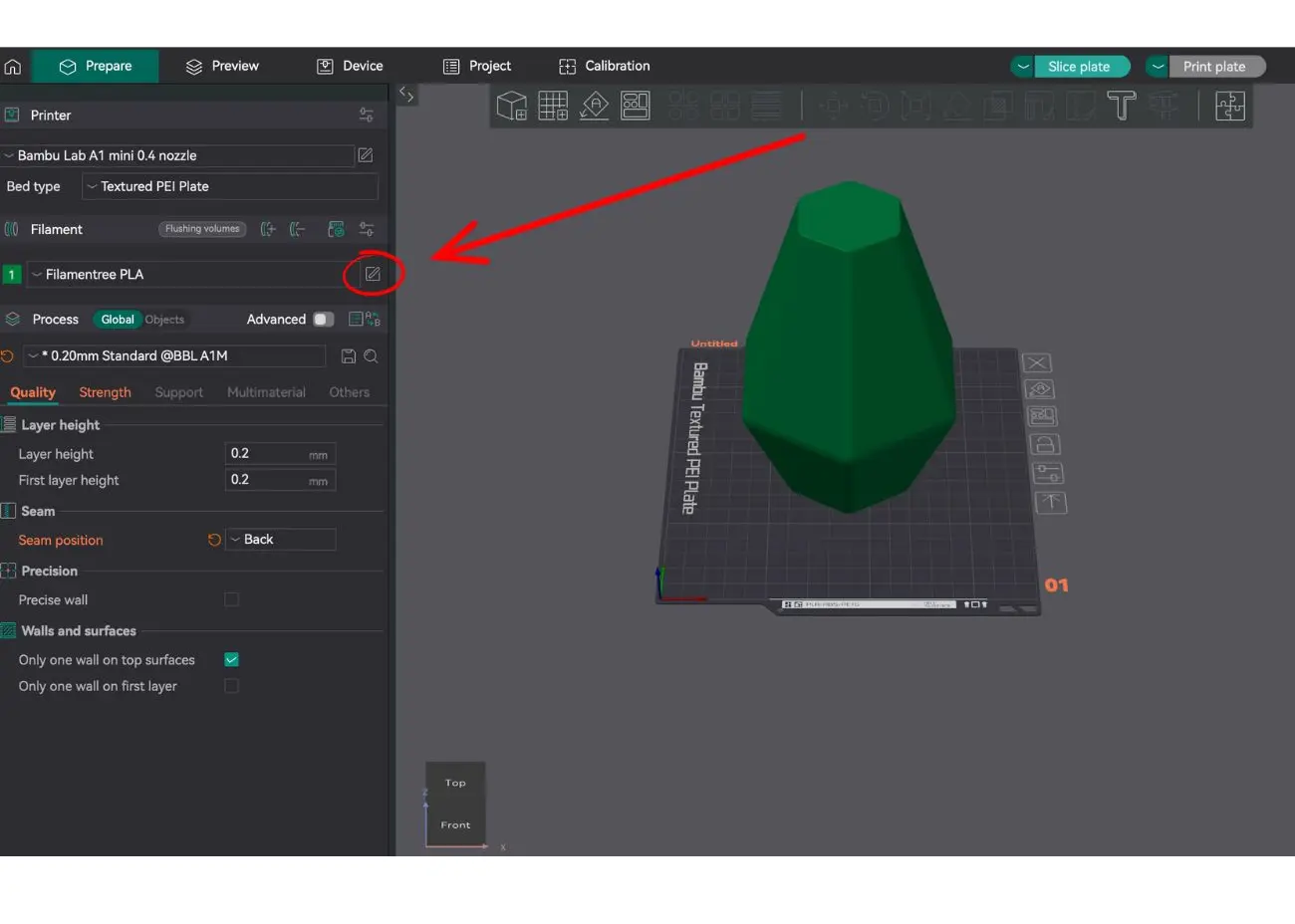

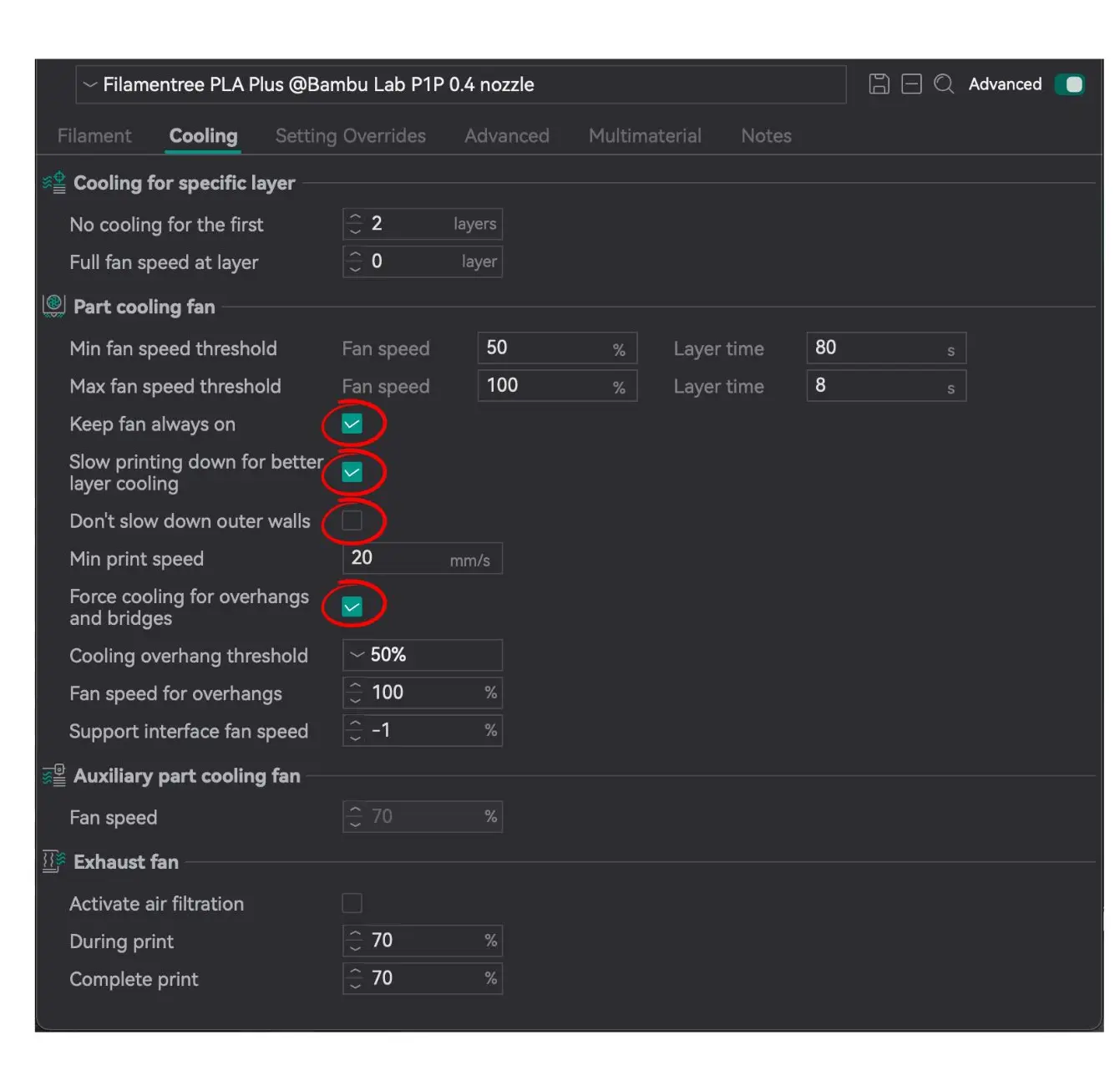

PLA Plus (PLA+) – Print Settings

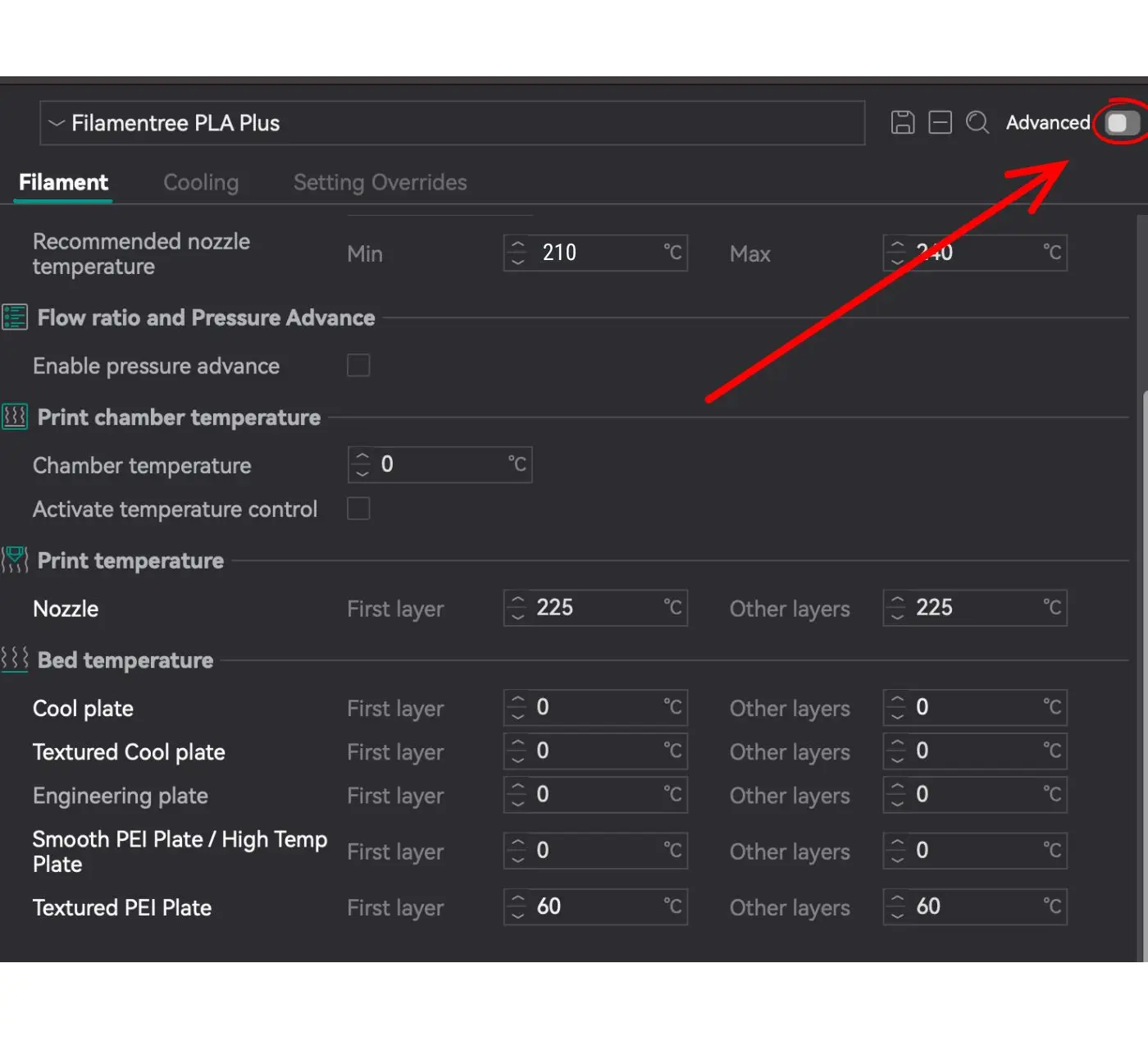

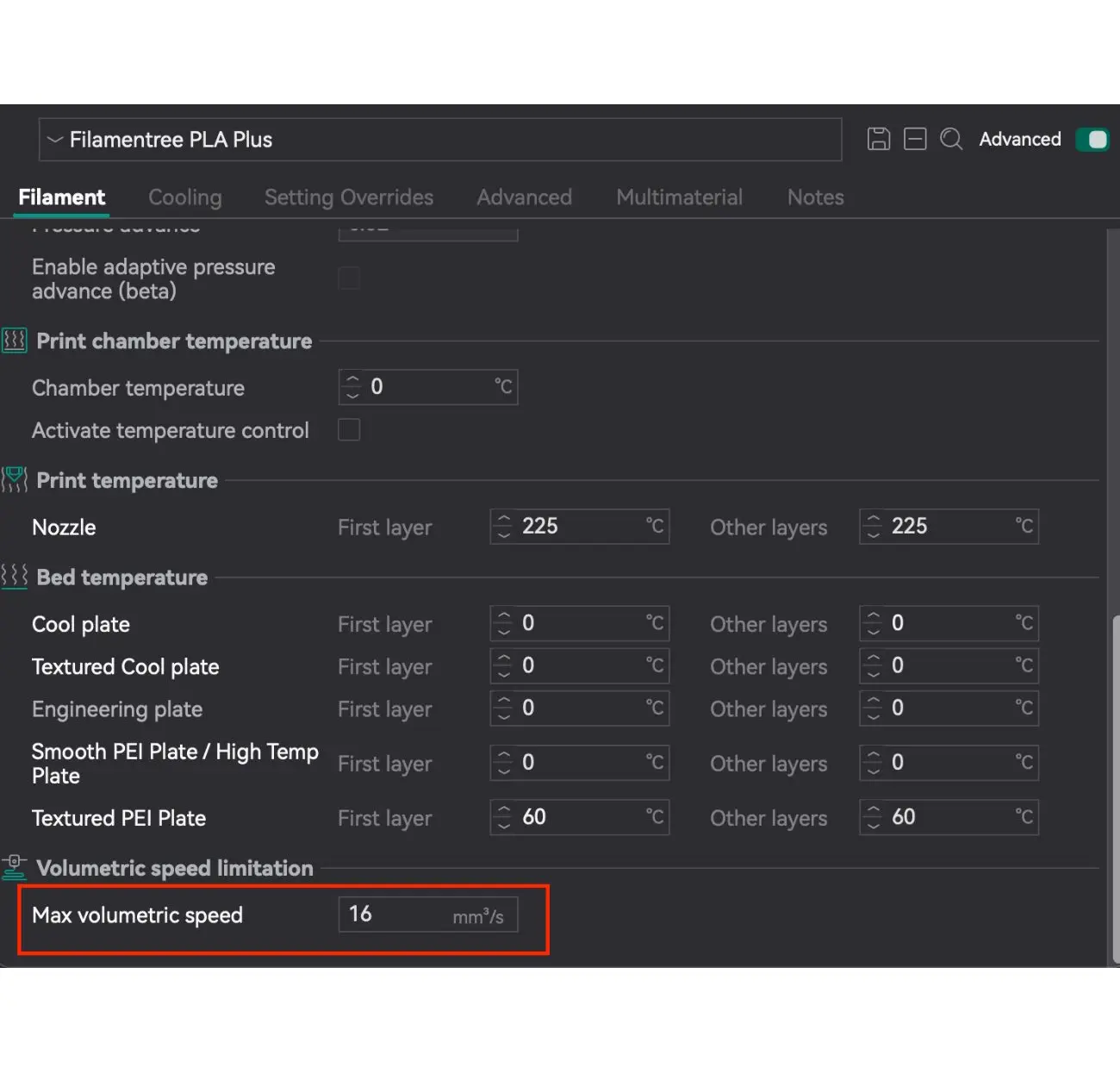

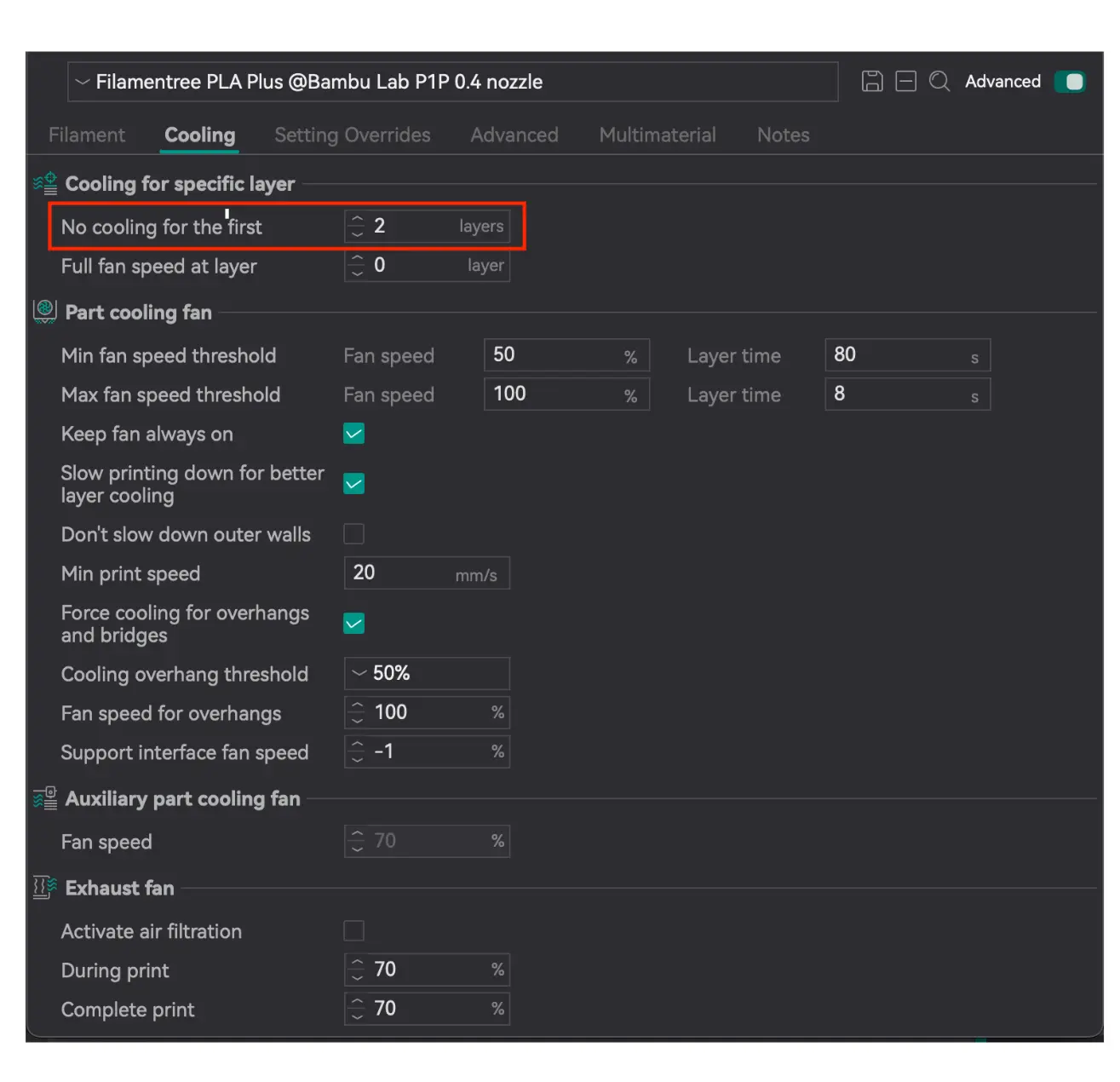

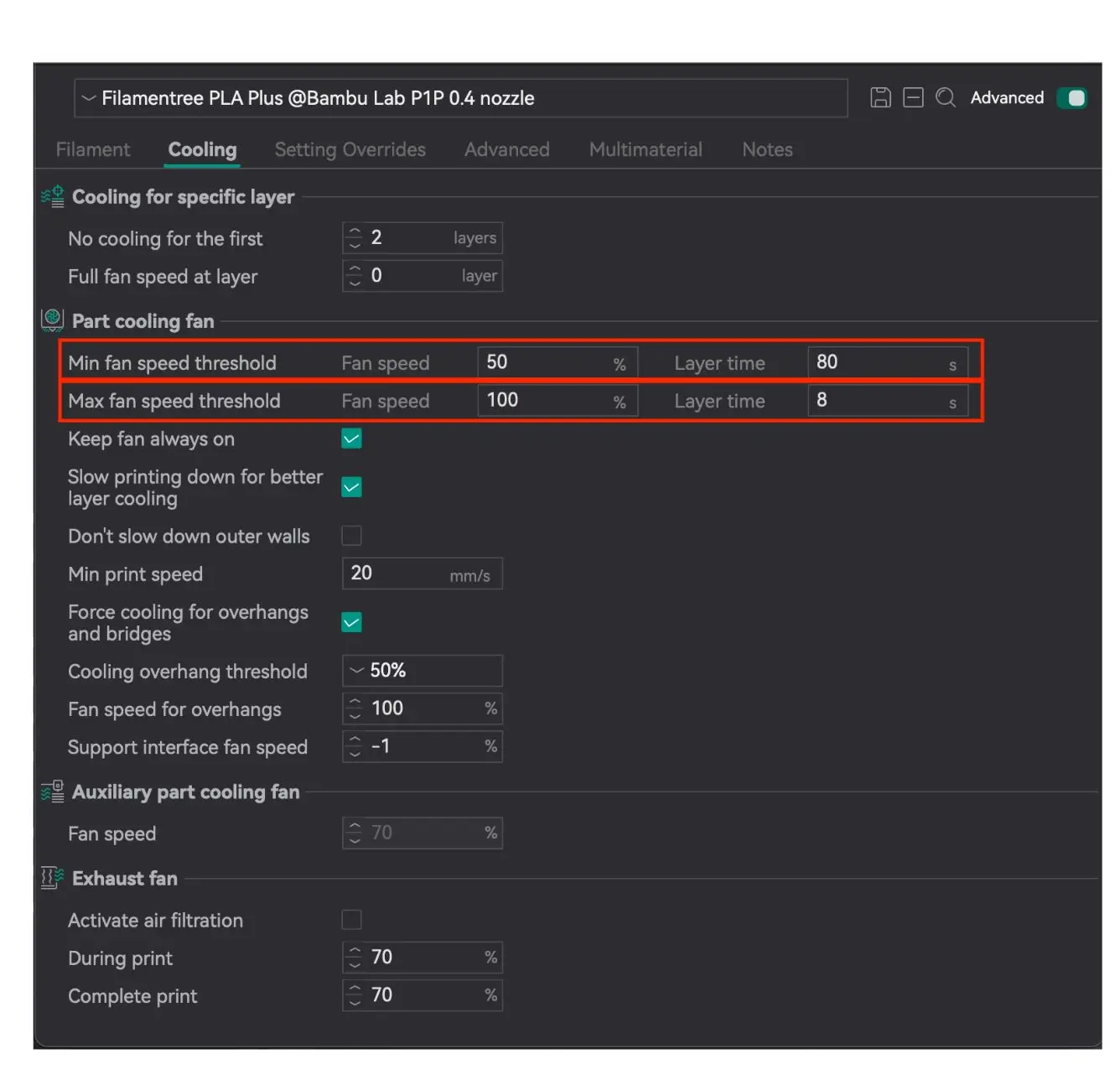

PLA Plus (PLA+) is an improved version of classic PLA, offering higher strength, better flexibility, and increased durability. To achieve the best printing results, it is essential to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

Using the correct printing parameters for PLA Plus is critically important for achieving high-quality results. PLA Plus, as an improved version of standard PLA, requires precise settings to optimize its properties. Following the recommended settings allows you to fully leverage the benefits of PLA Plus, ensuring strong, aesthetically appealing, and durable prints.