PLA Plus Olive Green 1kg – Prémiový filament pre 3D tlač

PLA Plus Pure Green je prémiový 3D tlačový filament s čistým, sviežim zeleným odtieňom, ktorý symbolizuje energiu, rovnováhu a prírodu. Tento odtieň je ideálny pre dizajnové, ekologické aj technické projekty, kde sa spája precíznosť s vizuálnou atraktivitou. PLA Plus Pure Green ponúka vynikajúcu pevnosť, hladký povrch a jednoduché spracovanie – skvelá voľba pre všetkých tvorcov, ktorí hľadajú kvalitu a živú farbu v jednom.

Hlavné výhody

- Čistá zelená farba: Jasný a vyvážený odtieň zelenej, ktorý dodáva výtlačkom prirodzený a svieži vzhľad.

- Vysoká pevnosť a pružnosť: PLA Plus je pevnejší a odolnejší než bežné PLA, čo zaručuje trvácne a stabilné výtlačky.

- Jednoduché použitie: Výborná priľnavosť, minimálne riziko deformácií a kompatibilita s väčšinou 3D tlačiarní.

- Ekologický materiál: Vyrobený z biologicky odbúrateľných, netoxických surovín, vhodný pre ekologicky uvedomelých používateľov.

Aplikácie

- Dekoratívne a interiérové projekty: Ideálny na výrobu dizajnových doplnkov, rastlinných dekorácií či modelov s prírodnou tematikou.

- Ekologické a edukačné projekty: Perfektný pre environmentálne modely, školské výstupy alebo prezentačné prototypy.

- Umelecké diela a kreatívne výtlačky: Skvelý pre figúrky, šperky alebo moderné umelecké objekty.

- Funkčné prototypy: Vhodný pre pevné, presné a zároveň esteticky atraktívne modely.

- Reklamné a prezentačné predmety: Pôsobivý vzhľad pre logá, nápisy a ukážkové výrobky.

Ideálne pre

- Dizajnérov a tvorcov, ktorí chcú sviežu a prírodnú farbu.

- Projekty zamerané na estetiku a udržateľnosť.

- Ekologicky uvedomelých používateľov hľadajúcich spoľahlivý filament.

- Kreatívne výtlačky spájajúce farbu, kvalitu a pevnosť.

PLA Plus Pure Green prináša dokonalú kombináciu odolnosti, spoľahlivosti a živej farby. Je ideálny pre všetkých, ktorí chcú, aby ich 3D výtlačky pôsobili prirodzene, sviežo a profesionálne.

| Colour | Pure Green |

| Weight | 1 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

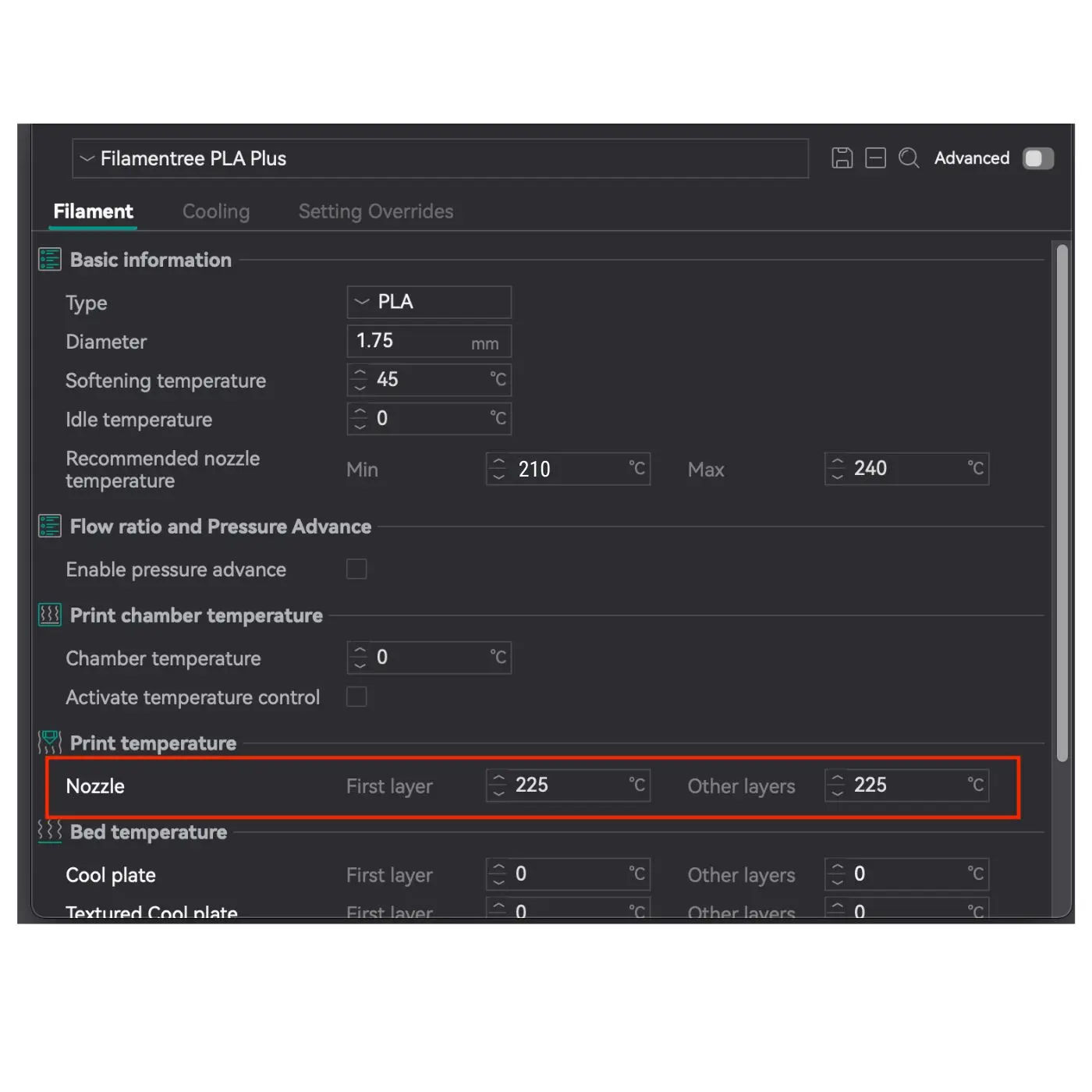

| Printing Temperature | 210-240°C |

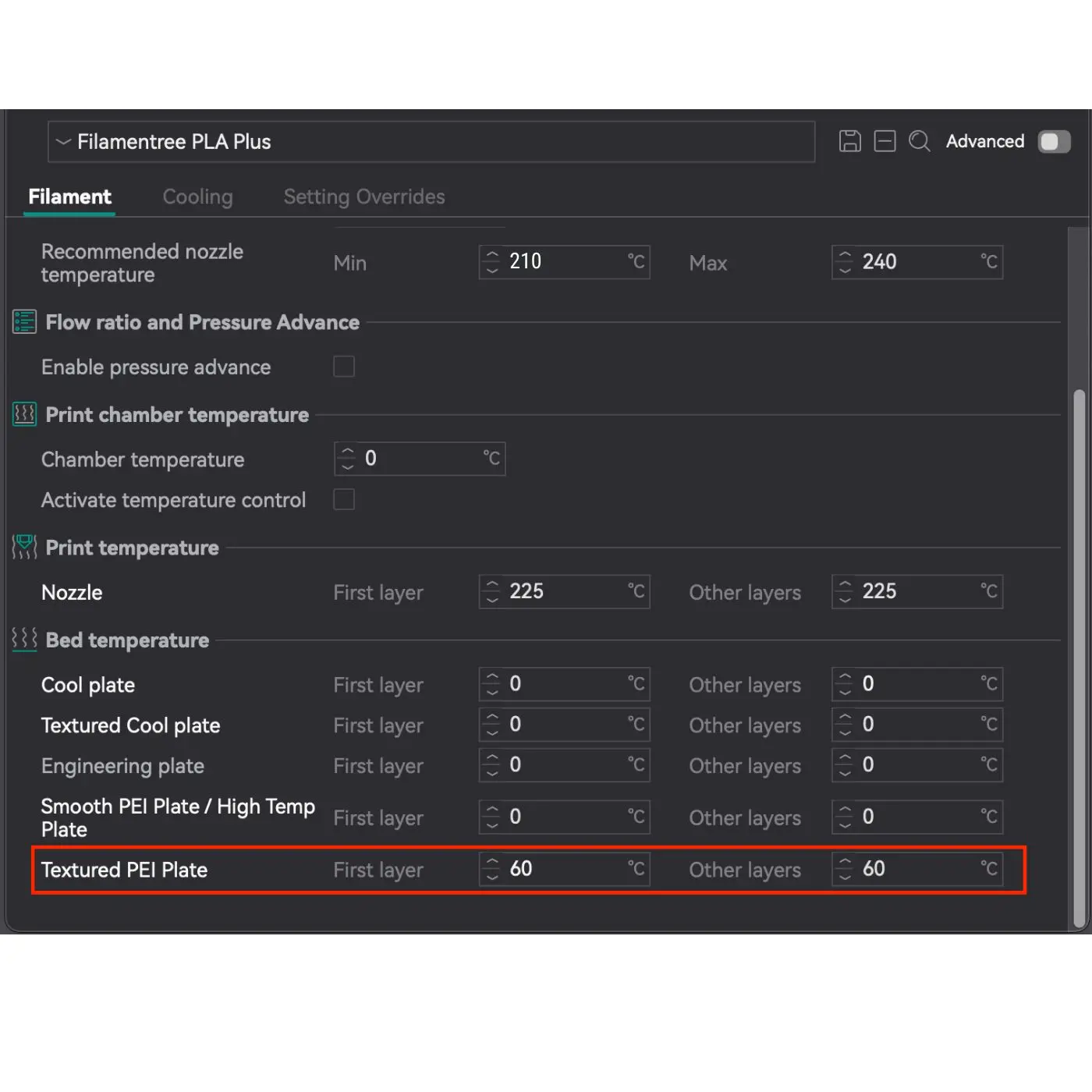

| Bed Temperature | 0–60°C (prints well without a heated bed) |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 50°C |

PLA Plus (PLA+) – Print Settings

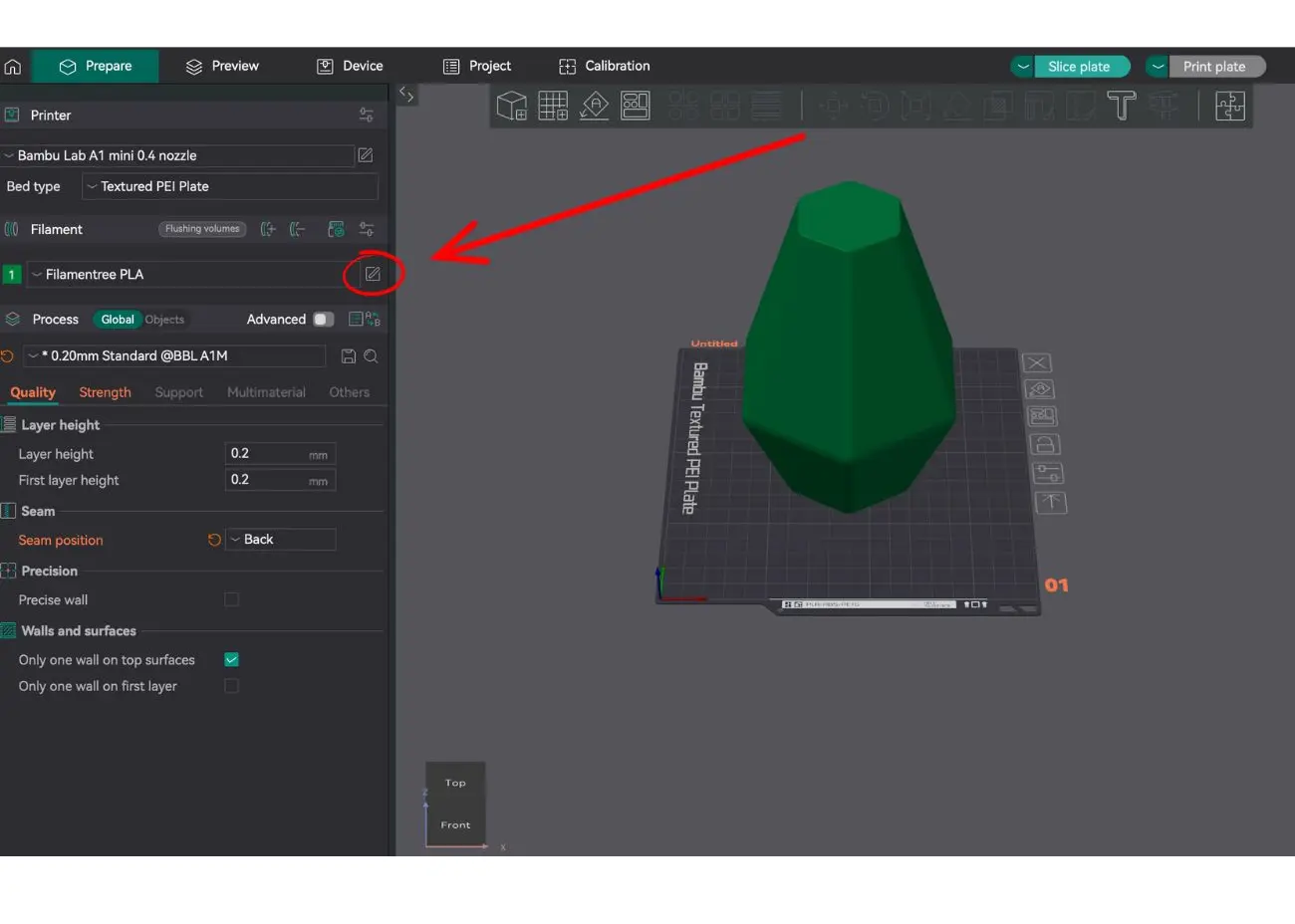

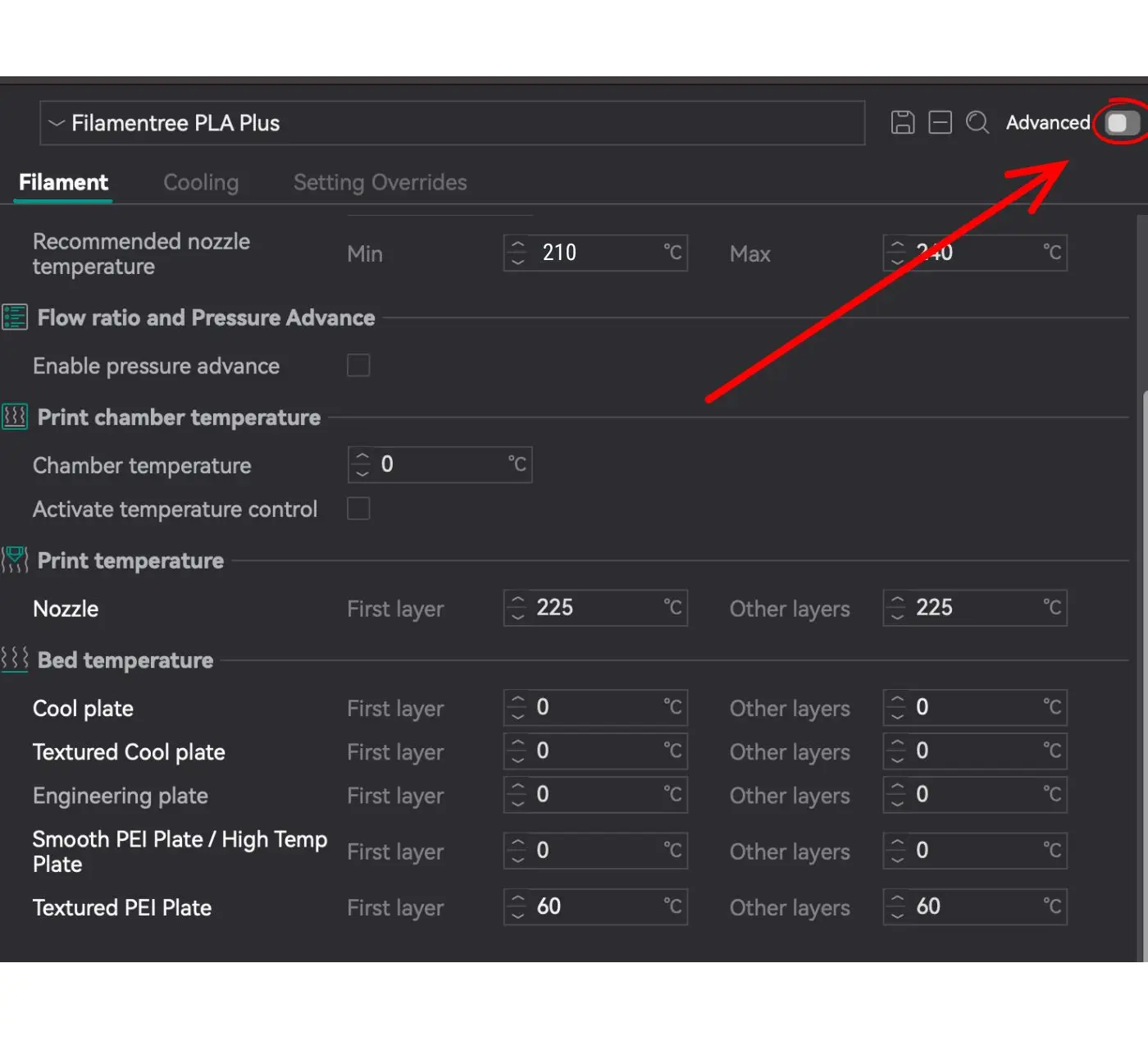

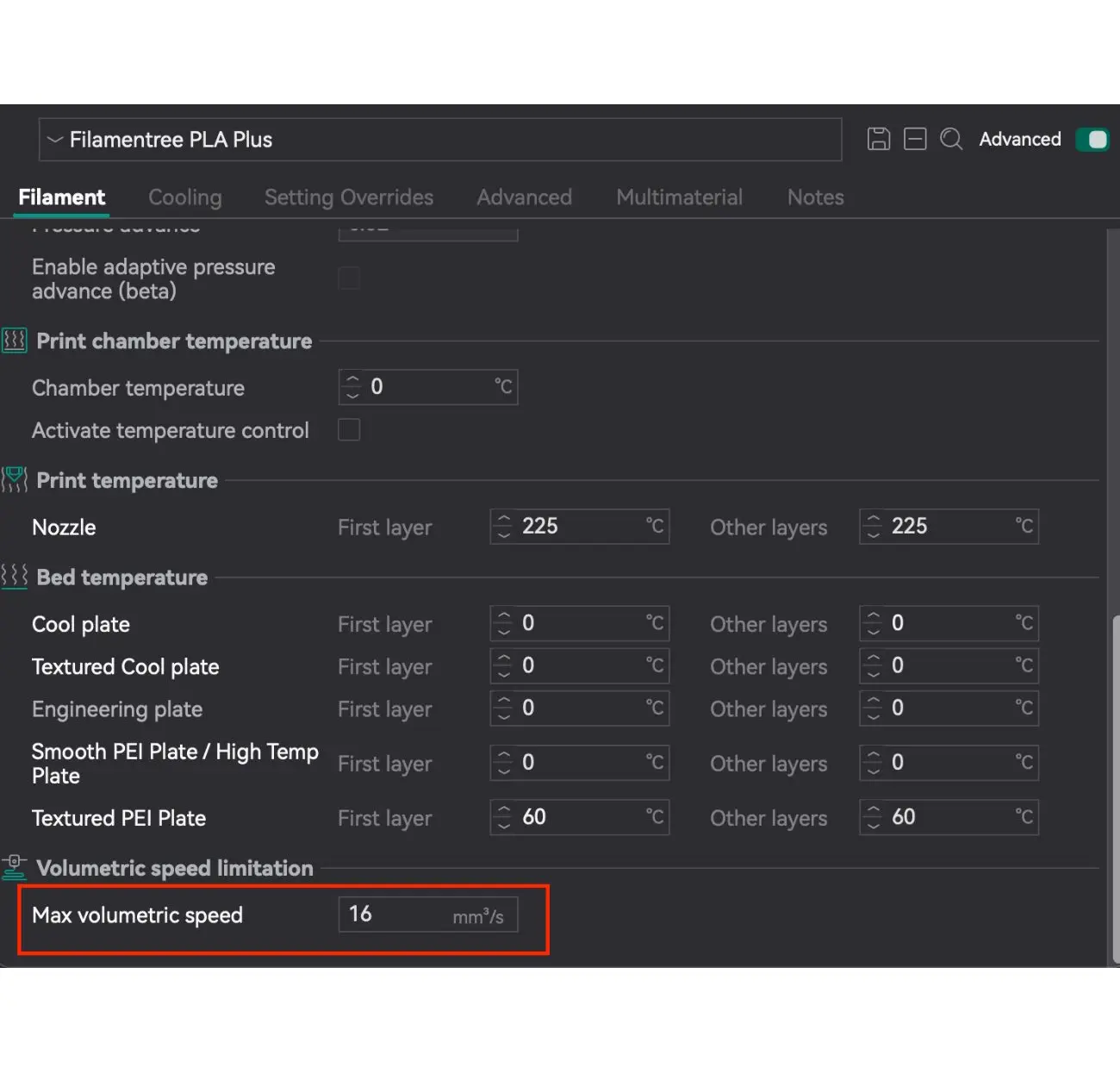

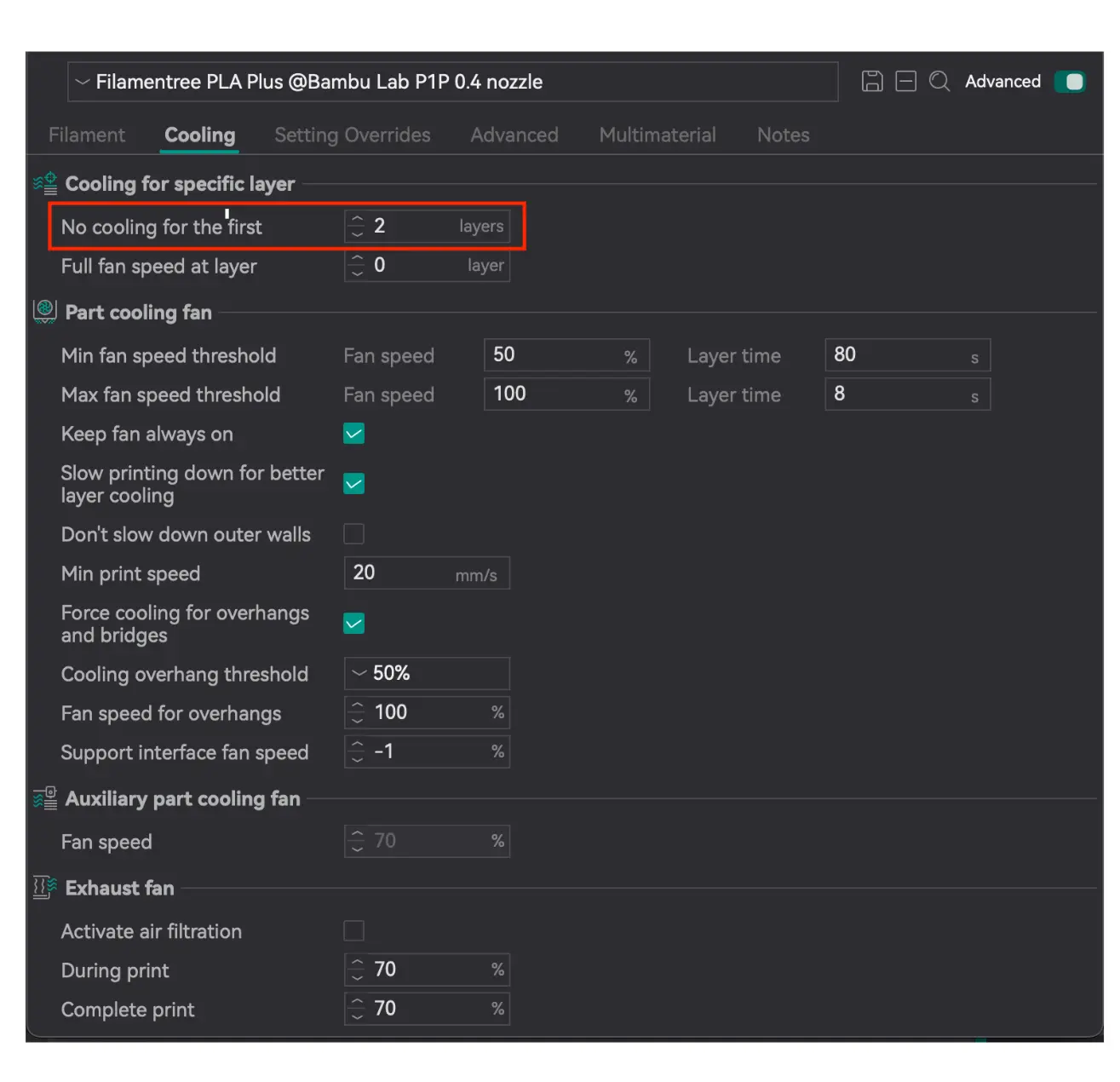

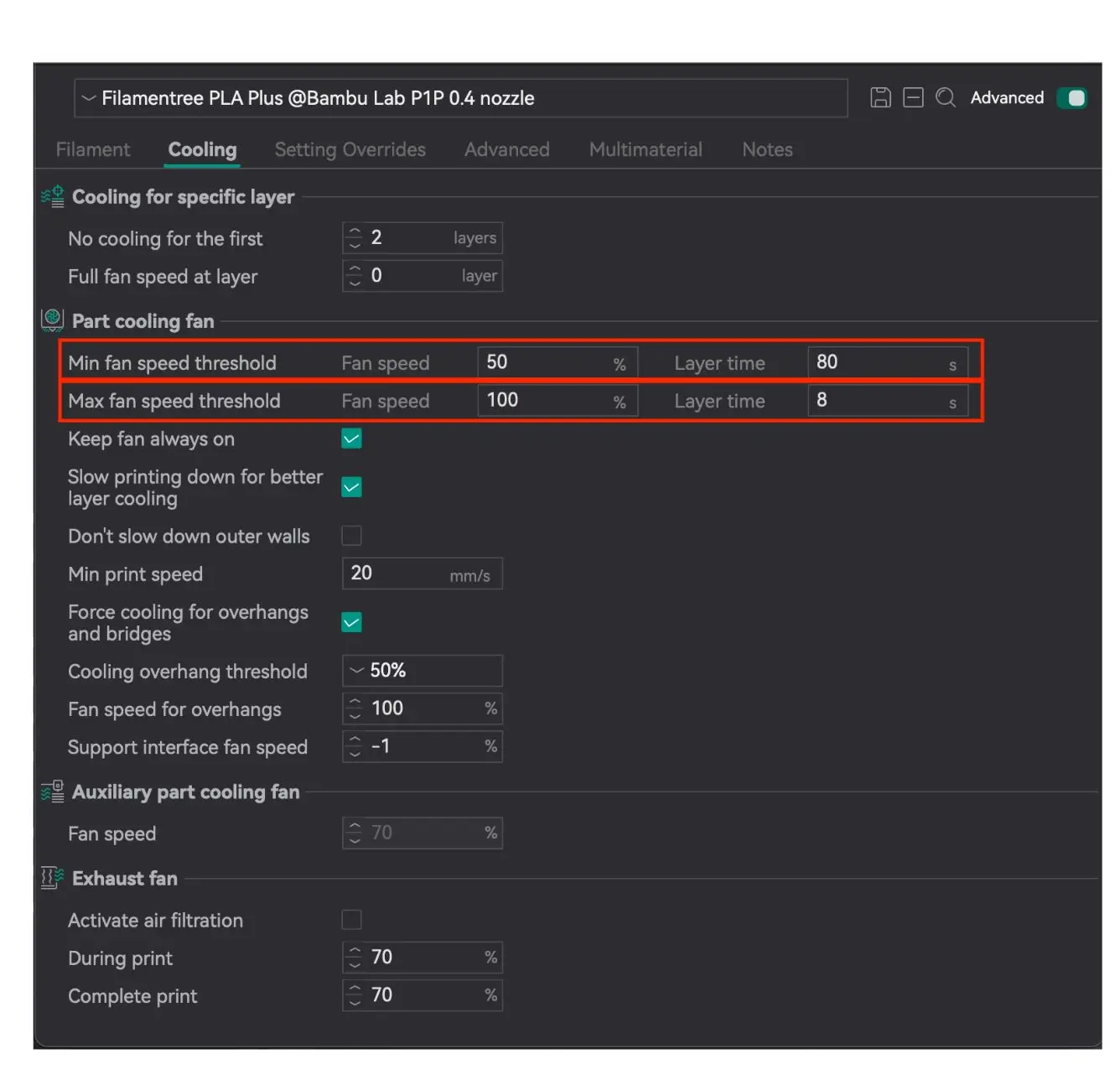

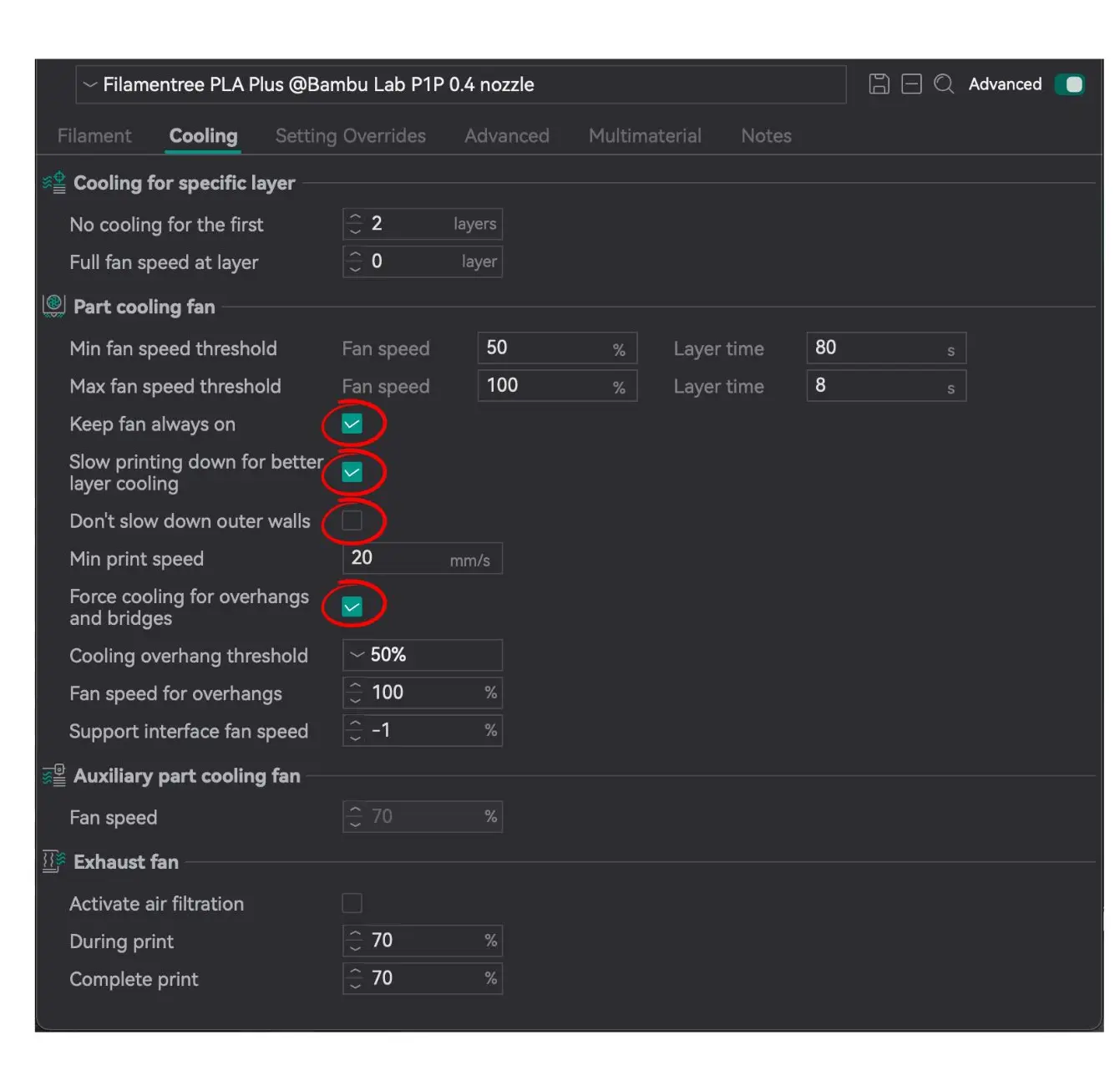

PLA Plus (PLA+) is an improved version of classic PLA, offering higher strength, better flexibility, and increased durability. To achieve the best printing results, it is essential to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

Using the correct printing parameters for PLA Plus is critically important for achieving high-quality results. PLA Plus, as an improved version of standard PLA, requires precise settings to optimize its properties. Following the recommended settings allows you to fully leverage the benefits of PLA Plus, ensuring strong, aesthetically appealing, and durable prints.