PLA Blaster Jet Black – Deep Contrast Meets High Performance

PLA Blaster Jet Black is a high-grade filament engineered for creators who demand maximum contrast, reliable strength, and flawless surface quality. Its rich, matte black finish delivers striking visual depth, making details pop with every layer. Built on an enhanced PLA+ base, Jet Black combines superior toughness with exceptional print reliability, ensuring your parts look sharp and perform under stress.

Key Benefits:

- Enhanced Toughness: PLA+ formulation provides improved impact resistance and durability over standard PLA.

- Consistent Printing: Excellent layer adhesion and minimal warping for clean, dependable results.

- Broad Compatibility: Works seamlessly on all FDM/FFF printers with a 0.4 mm nozzle.

- Eco-Friendly: Made from biodegradable, non-toxic materials—perfect for sustainable projects.

Applications:

- Prototypes & Functional Parts: Ideal for gear housings, brackets, and end-use components requiring both strength and aesthetics.

- Artistic & Decorative Models: Perfect for sculptures, miniatures, and display pieces where contrast enhances form.

- Tooling & Jigs: Provides clear visibility of edges and tolerances in fixtures, templates, and guides.

- Cosplay & Props: Creates bold, dramatic elements for costumes and accessories.

- Everyday Printing: A go-to “default” filament for users who prefer sleek, professional black prints.

| Colour | Jet Black |

| Weight | 1 kg |

| Diameter tolerance | < 0,05 mm |

| Diameter | 1,75 mm |

| Printing Temperature | 230-240°C |

| Bed Temperature | 40-60°C |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 110°C |

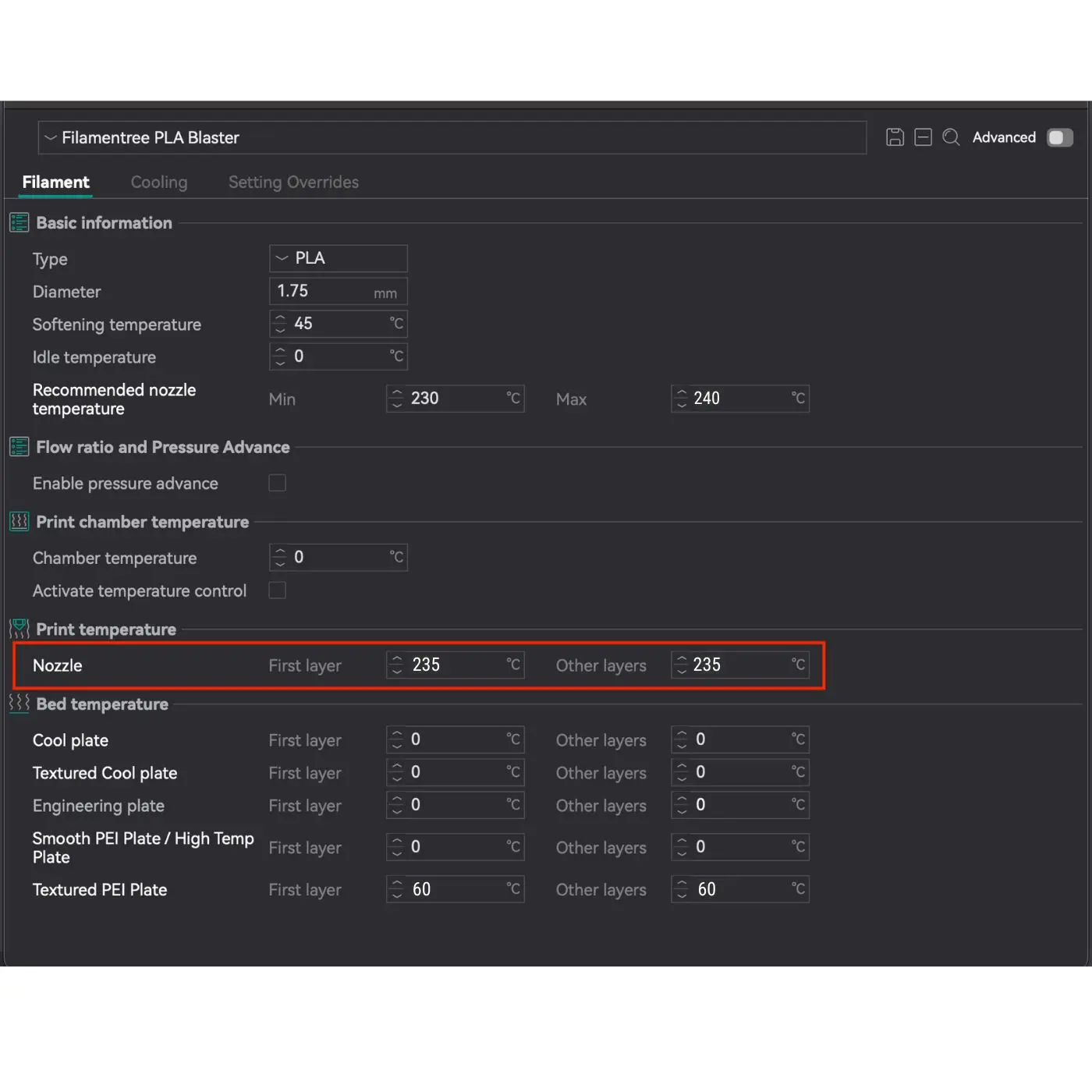

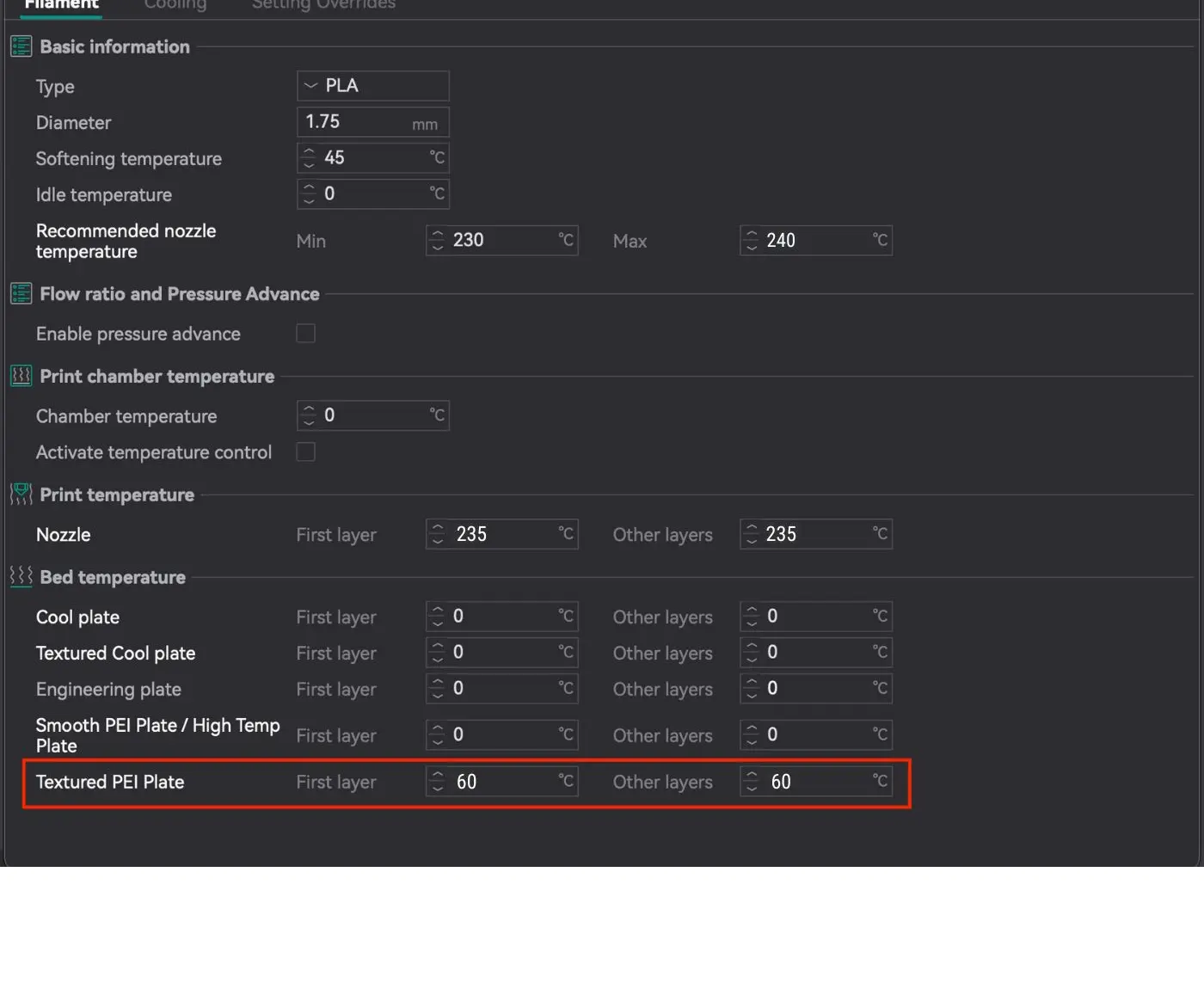

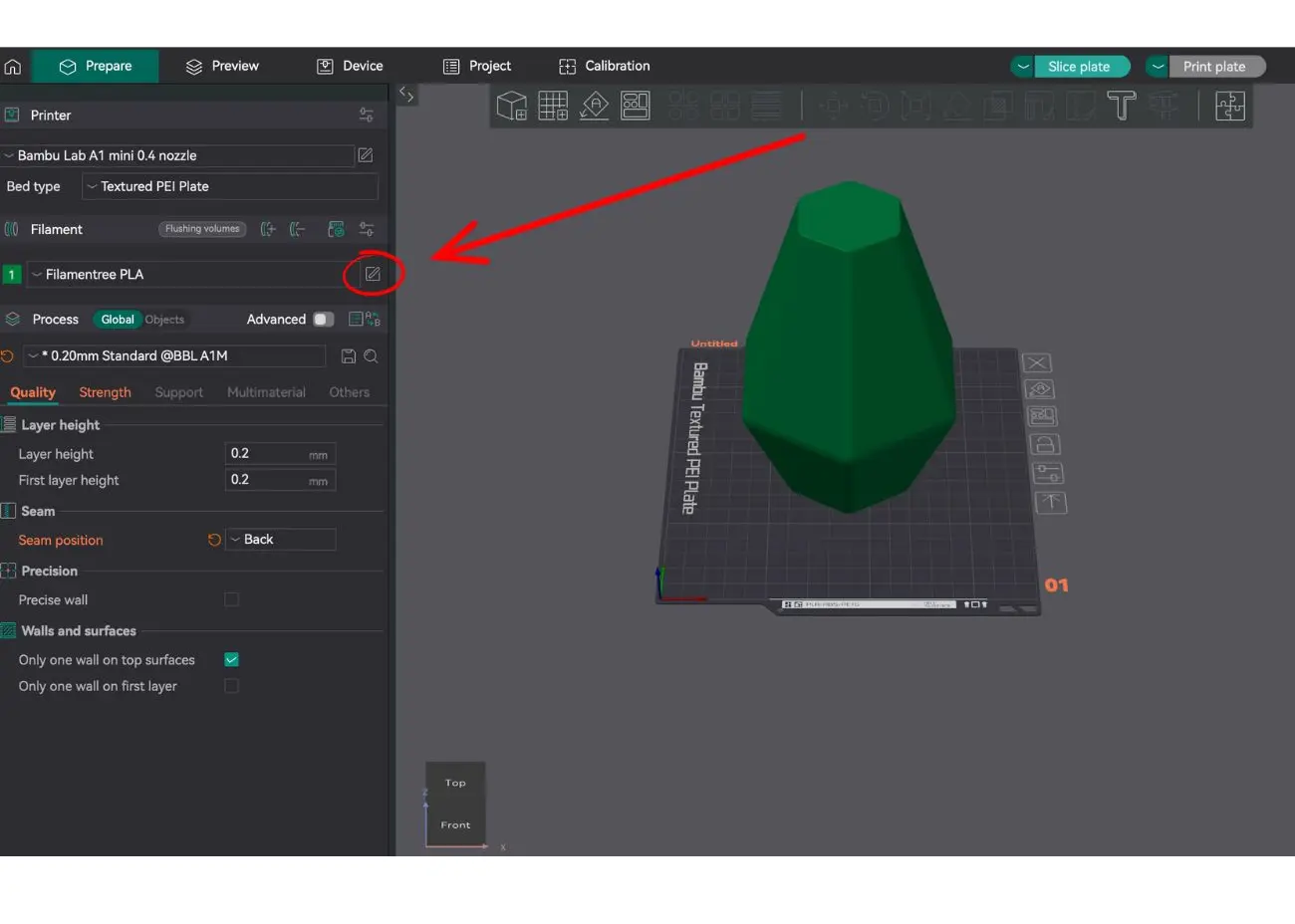

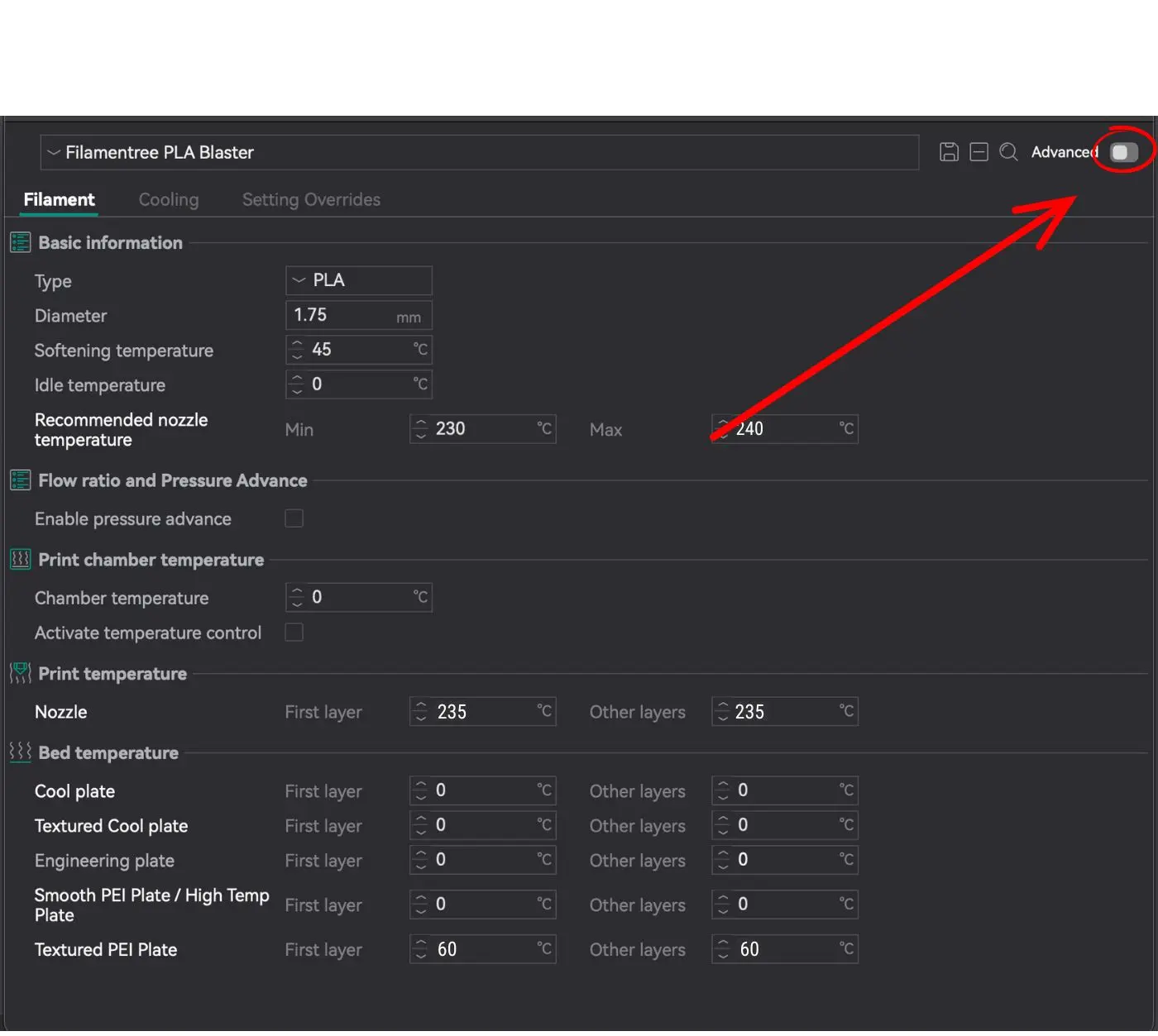

PLA Blaster – Print Settings

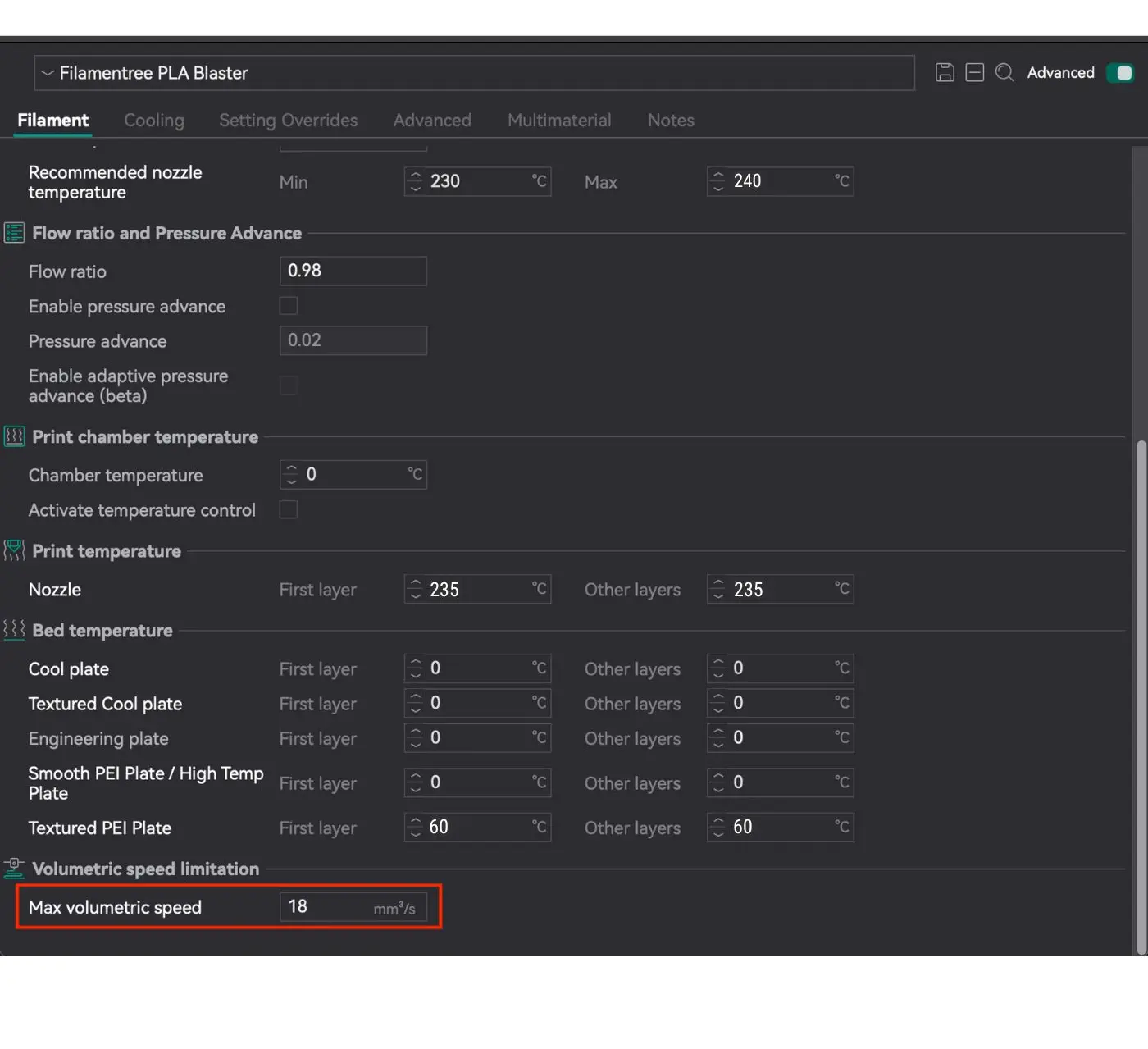

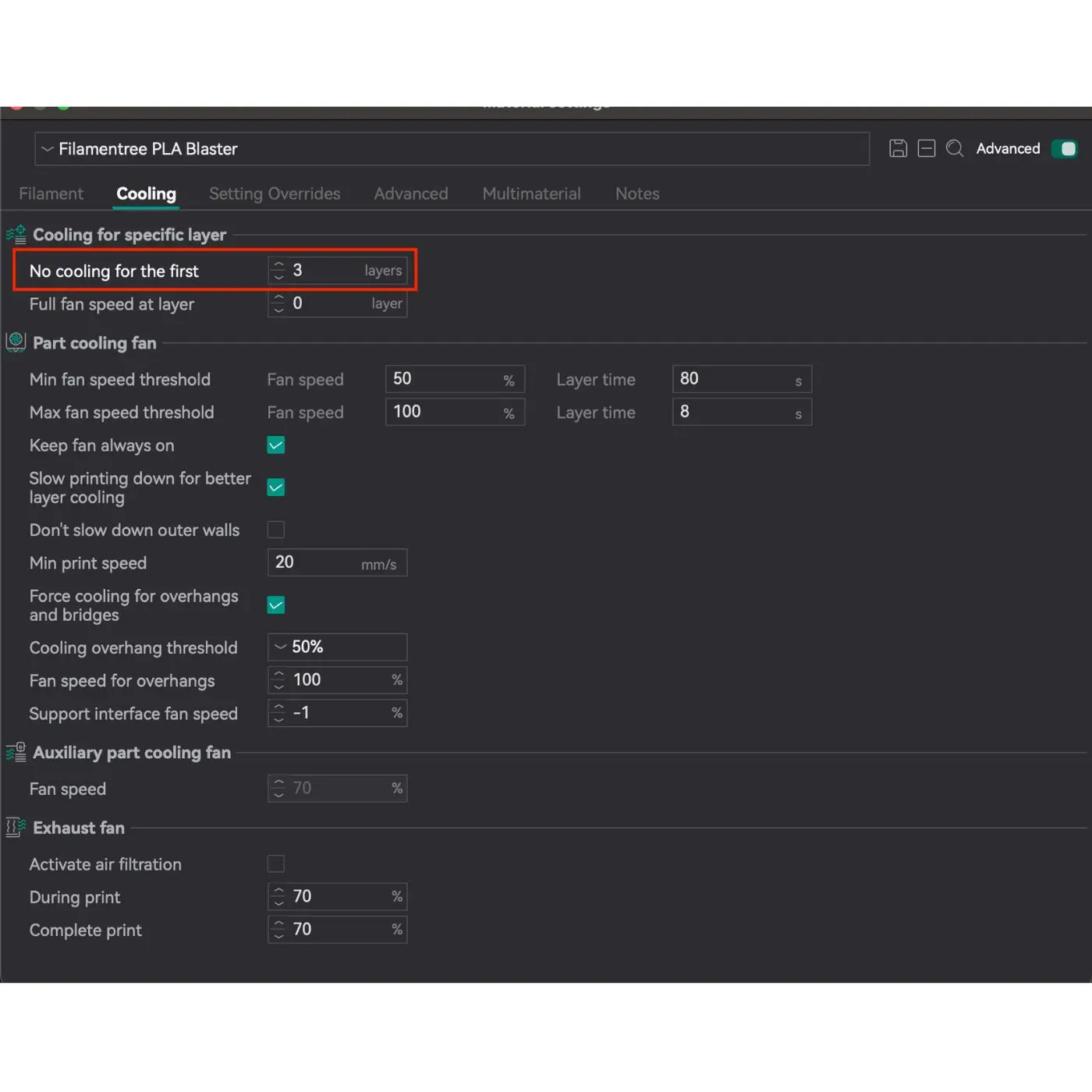

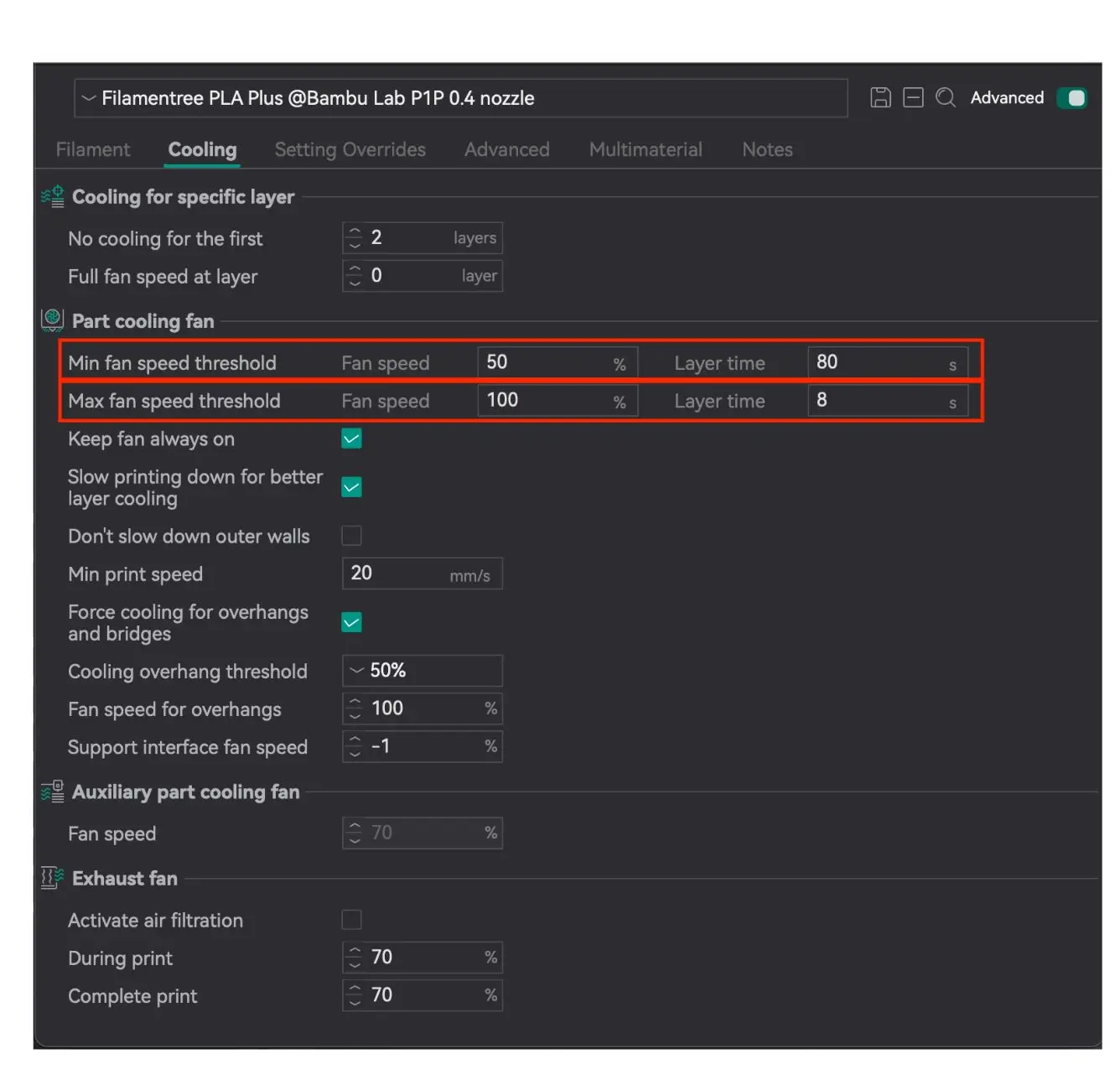

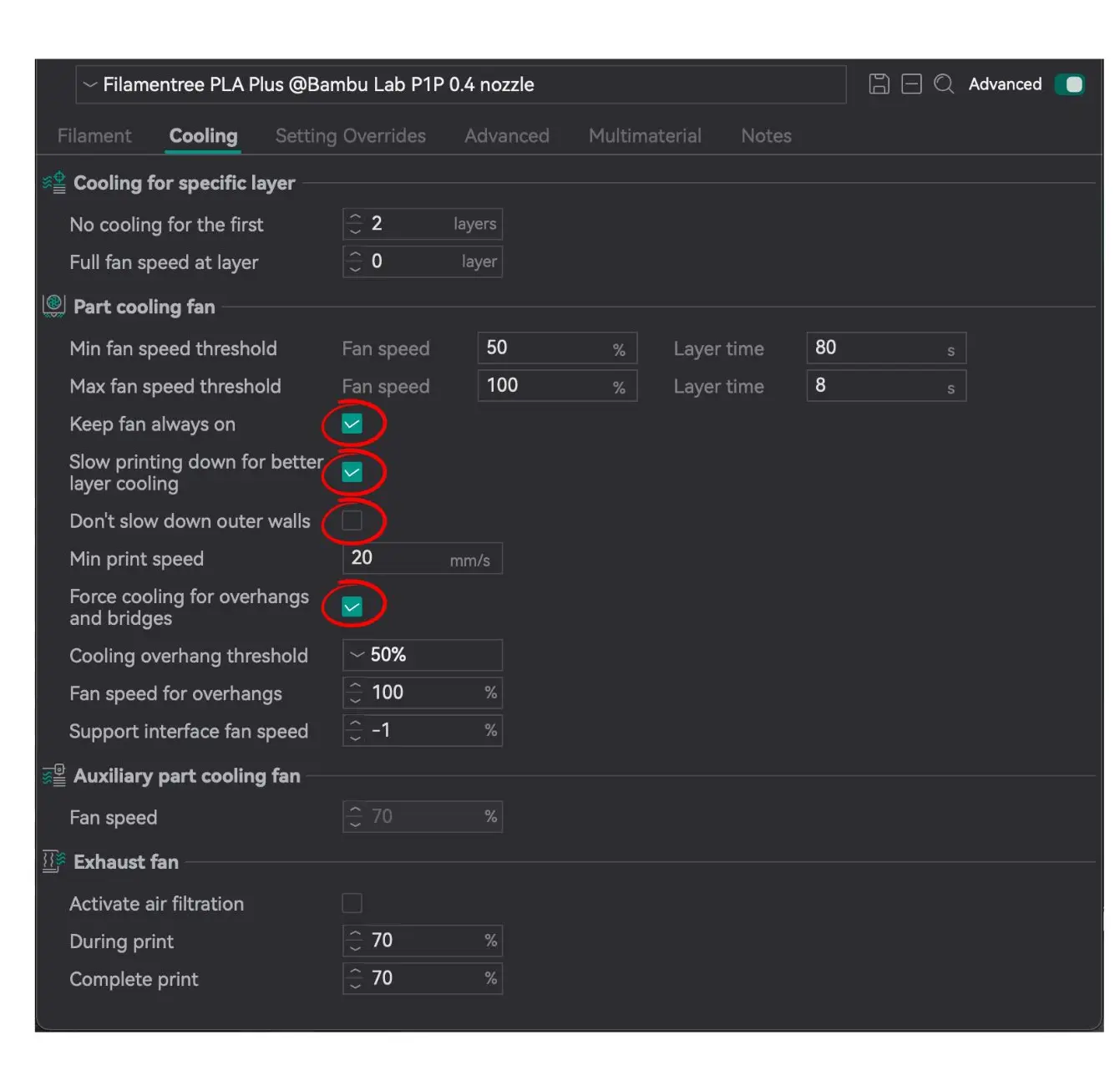

PLA Blaster is an improved version of classic PLA, offering higher strength, better durability, and excellent mechanical properties. To achieve optimal printing results, it is important to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

Using the correct printing parameters for PLA Blaster is essential for achieving high-quality results. As an enhanced version of standard PLA, PLA Blaster requires precise settings to fully optimize its advanced properties. By following the recommended settings, you can take full advantage of its increased strength, durability, and excellent print quality, ensuring reliable and visually appealing prints.