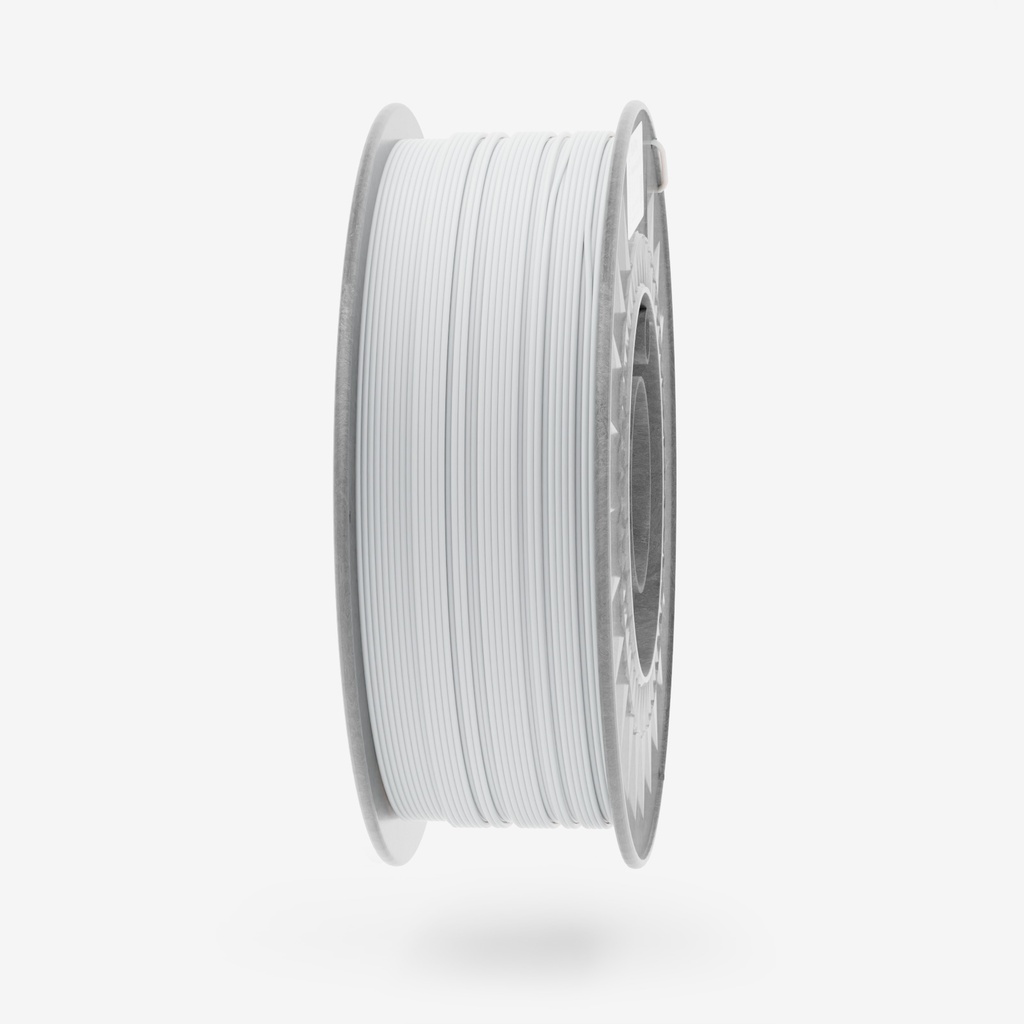

PLA Silk Shimmering White 1kg – Hodvábny efekt a luxusný lesk pre výnimočné výtlačky

PLA Silk Shimmering White je prémiový filament určený pre tvorcov, ktorí chcú svojim projektom dodať elegantný, perleťový vzhľad s výrazným hodvábnym odleskom. Spojenie kvalitného PLA materiálu a špeciálnej „silk“ zložky vytvára hladký povrch bez viditeľných vrstiev a dodáva výtlačkom exkluzívny charakter. Tento odtieň žiarivo bielej s jemným shimmer efektom je ideálny pre dekorácie, darčekové predmety, umelecké modely či reprezentatívne prototypy.

Hlavné výhody:

- Hodvábny lesk a perleťový efekt: Filament vytvára hladké povrchy s luxusným odleskom, ktoré zvýraznia každý detail a dodajú výtlačkom profesionálny umelecký vzhľad.

- Hladký povrch bez viditeľných vrstiev: Modifikovaná formula Silk zabezpečuje minimálnu viditeľnosť vrstiev a dokonale uhladený finiš bez nutnosti ďalšej postprodukcie.

- Jednoduchá a stabilná tlač: Výborná priľnavosť vrstiev, nízka náchylnosť na deformácie a kompatibilita s väčšinou FDM tlačiarní zaručujú spoľahlivé výsledky aj pri zložitejších modeloch.

- Ekologické zloženie: PLA Silk je vyrobený z biologicky odbúrateľného materiálu na rastlinnej báze, bezpečný a bez zápachu počas tlače.

Aplikácie:

- Umelecké modely a dekorácie: Ideálny pre vázy, sochy, ozdoby, doplnky a dizajnové prvky vyžadujúce wow efekt.

- Darčekové a reprezentatívne predmety: Perfektný pre ceny, trofeje, nápisy, logá a modely, ktoré majú zaujať na prvý pohľad.

- Estetické prototypy: Vytvorte atraktívne vizuálne návrhy produktov, ktoré vyzerajú profesionálne už bez povrchovej úpravy.

- Interiérové doplnky: Tlačte moderné dekorácie či prvky osvetlenia, ktoré ťažia z jemného perleťového lesku.

- Kreatívne projekty: Od cosplay doplnkov až po štýlové figúrky – Silk Shimmering White dodá každému výtvoru jedinečný šmrnc.

Ideálne pre:

- Tvorcov, ktorí chcú výtlačky s luxusným, hladkým a lesklým povrchom.

- Dekoratívne projekty, pri ktorých je vzhľad dôležitejší ako extrémna mechanická pevnosť.

- Produkty určené na prezentácie, výstavy alebo ako darčekové predmety.

- Každého, kto chce spojiť jednoduchú tlač PLA s estetickým efektom hodvábneho lesku.

PLA Silk Shimmering White v sebe spája technickú jednoduchosť PLA s výnimočným vizuálnym efektom. Ak chceš, aby tvoje výtlačky pôsobili prémiovo, elegantne a nezameniteľne, tento filament je tou správnou voľbou.

| Colour | Shimmering White |

| Weight | 1 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

| Printing Temperature | 210-240°C |

| Bed Temperature | 0–60°C (prints well without a heated bed) |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 50°C |

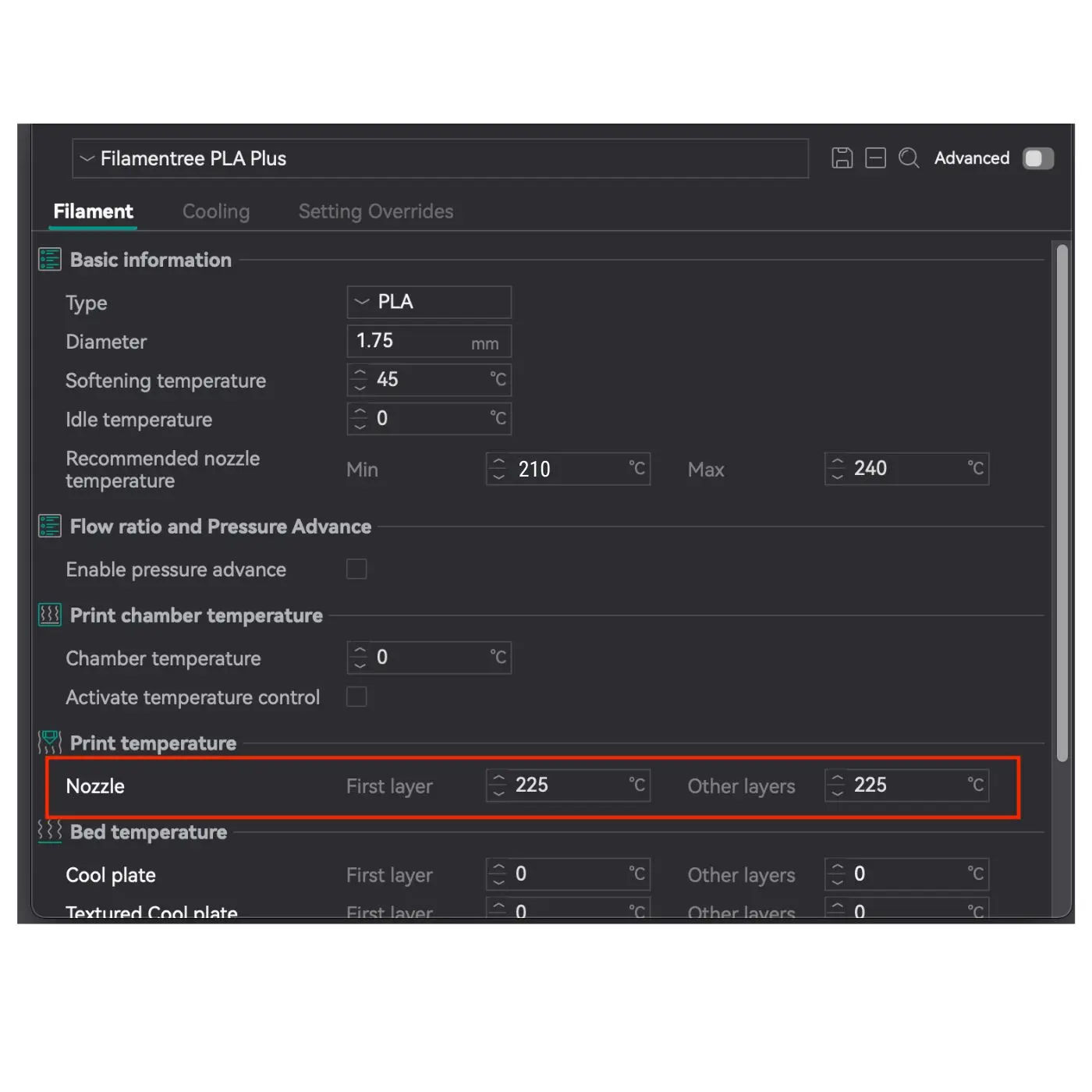

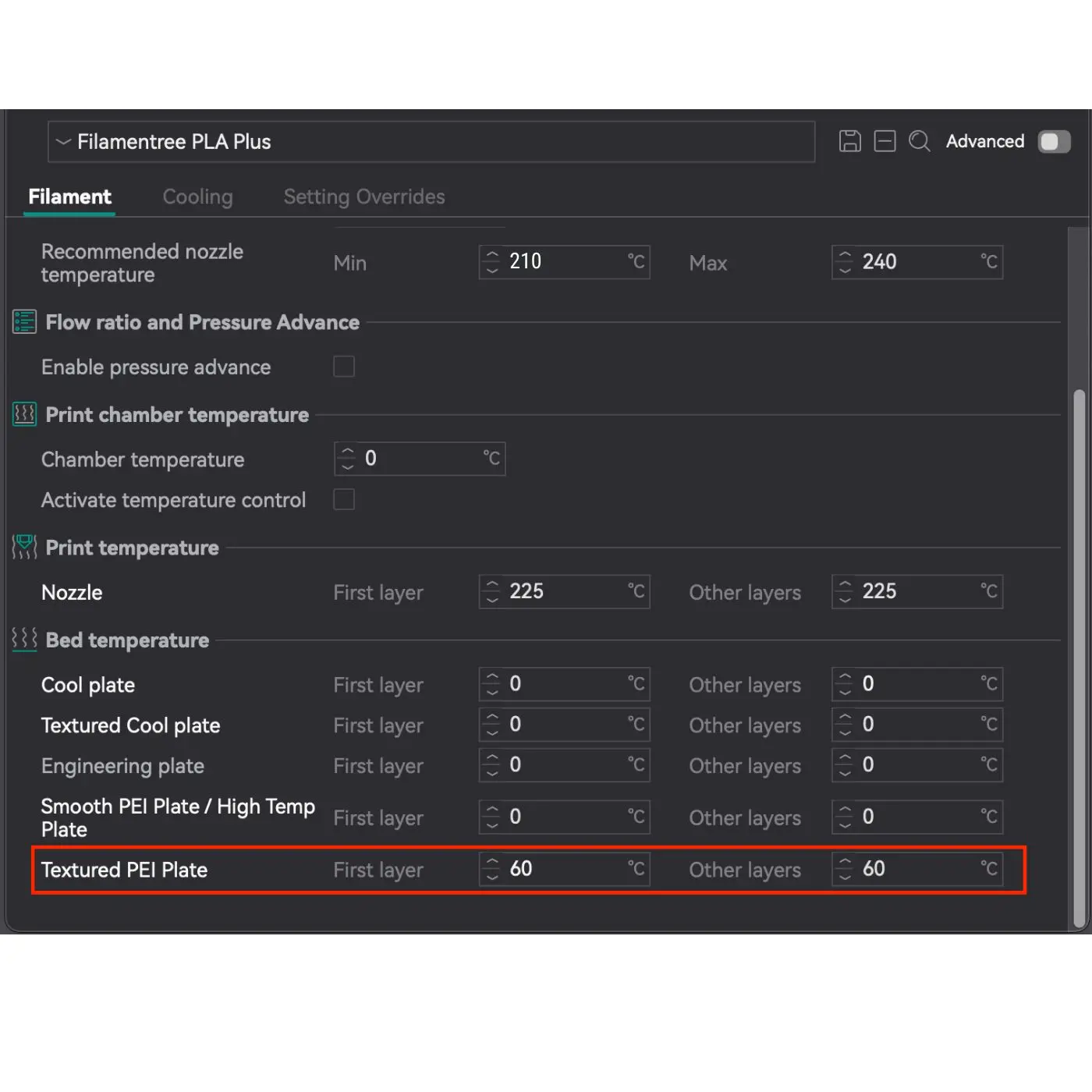

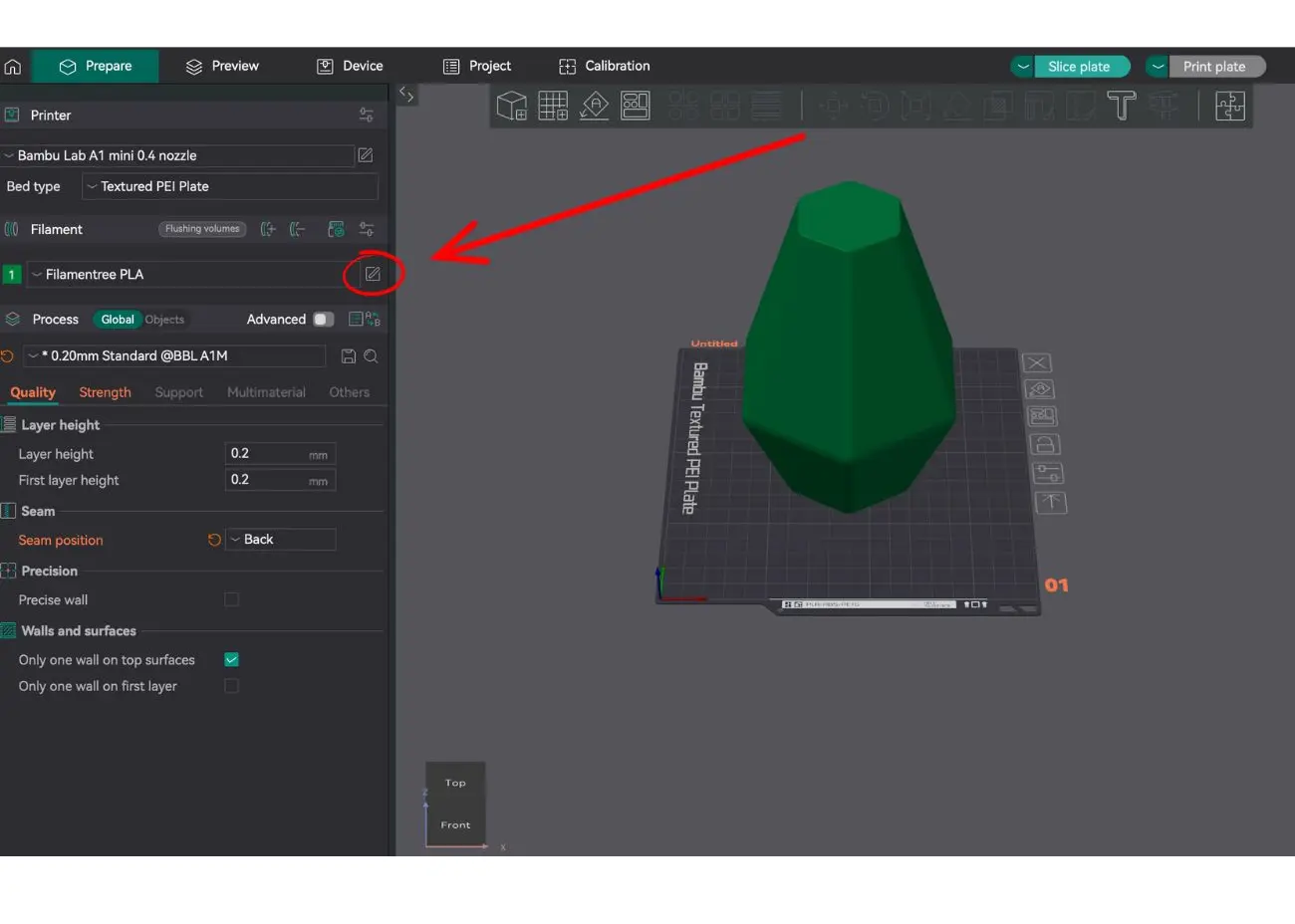

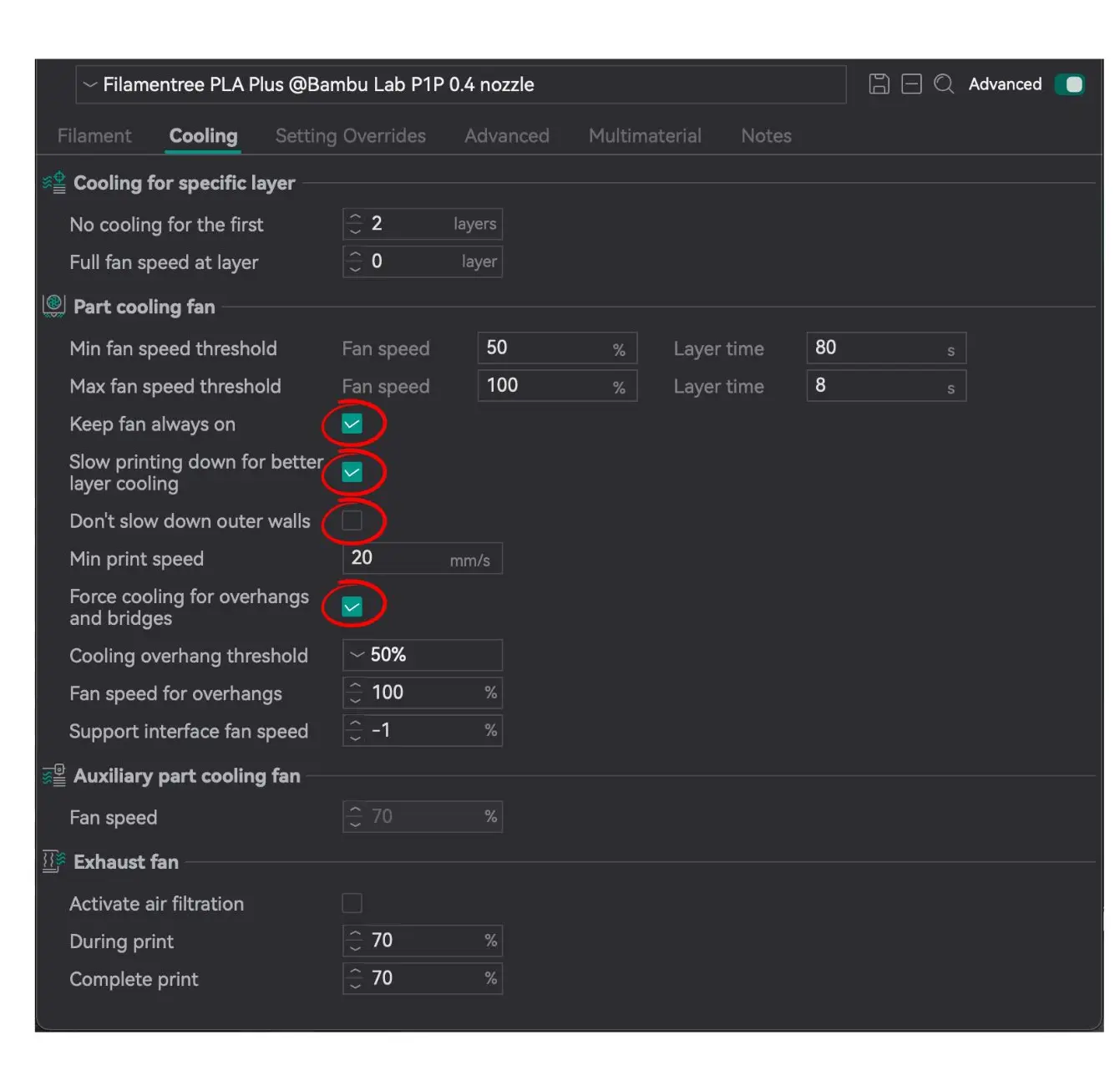

PLA Plus (PLA+) – Print Settings

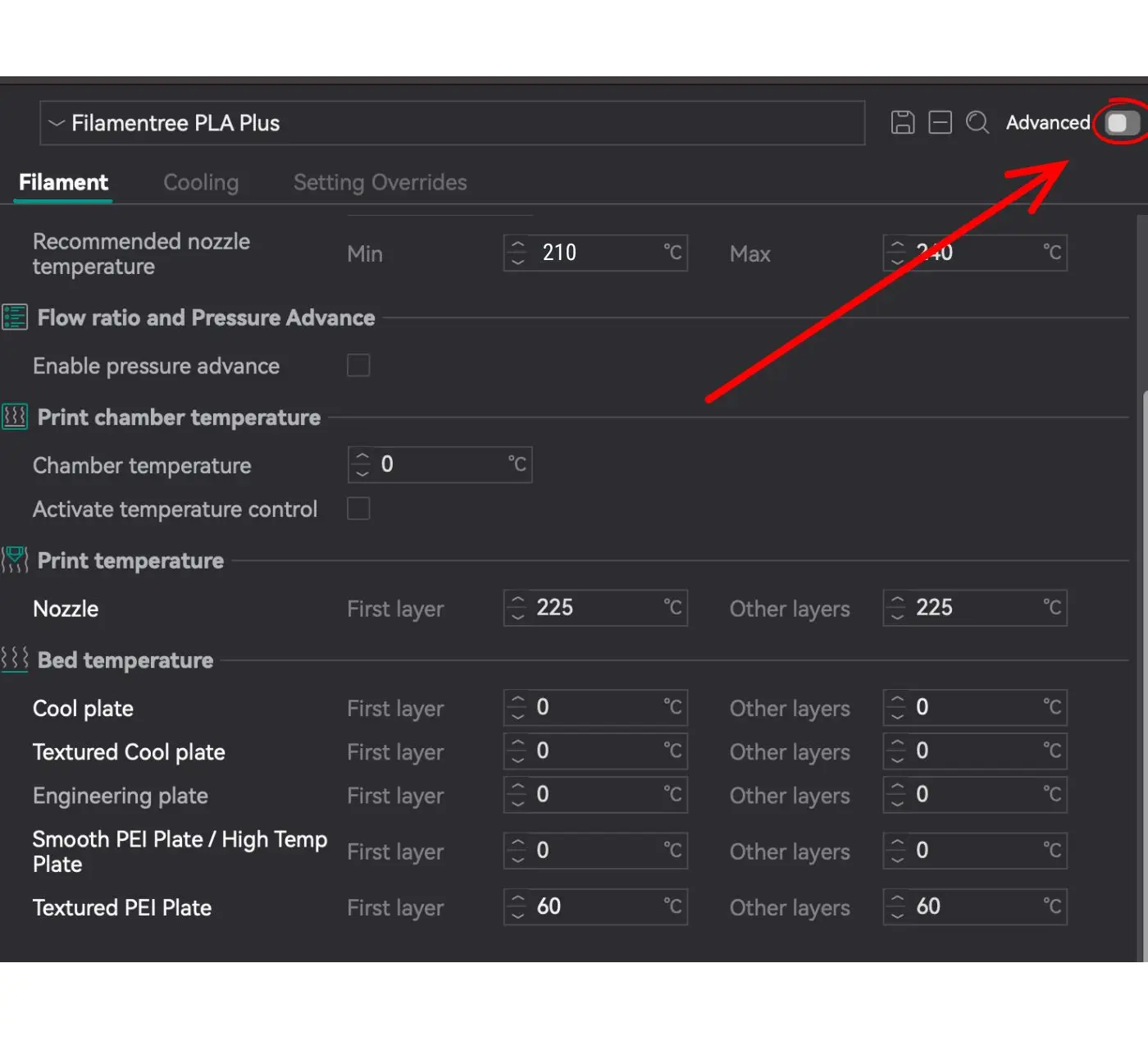

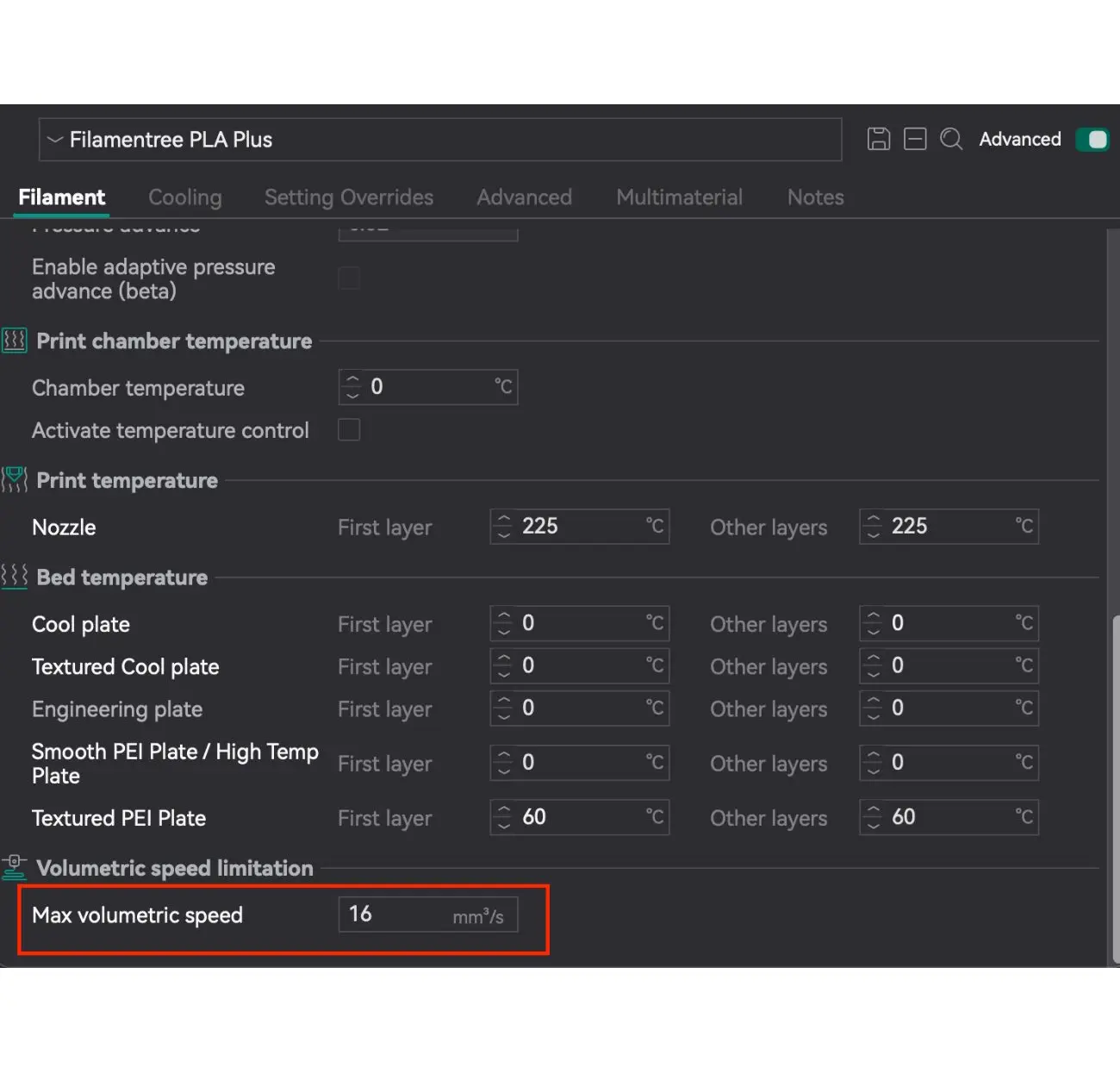

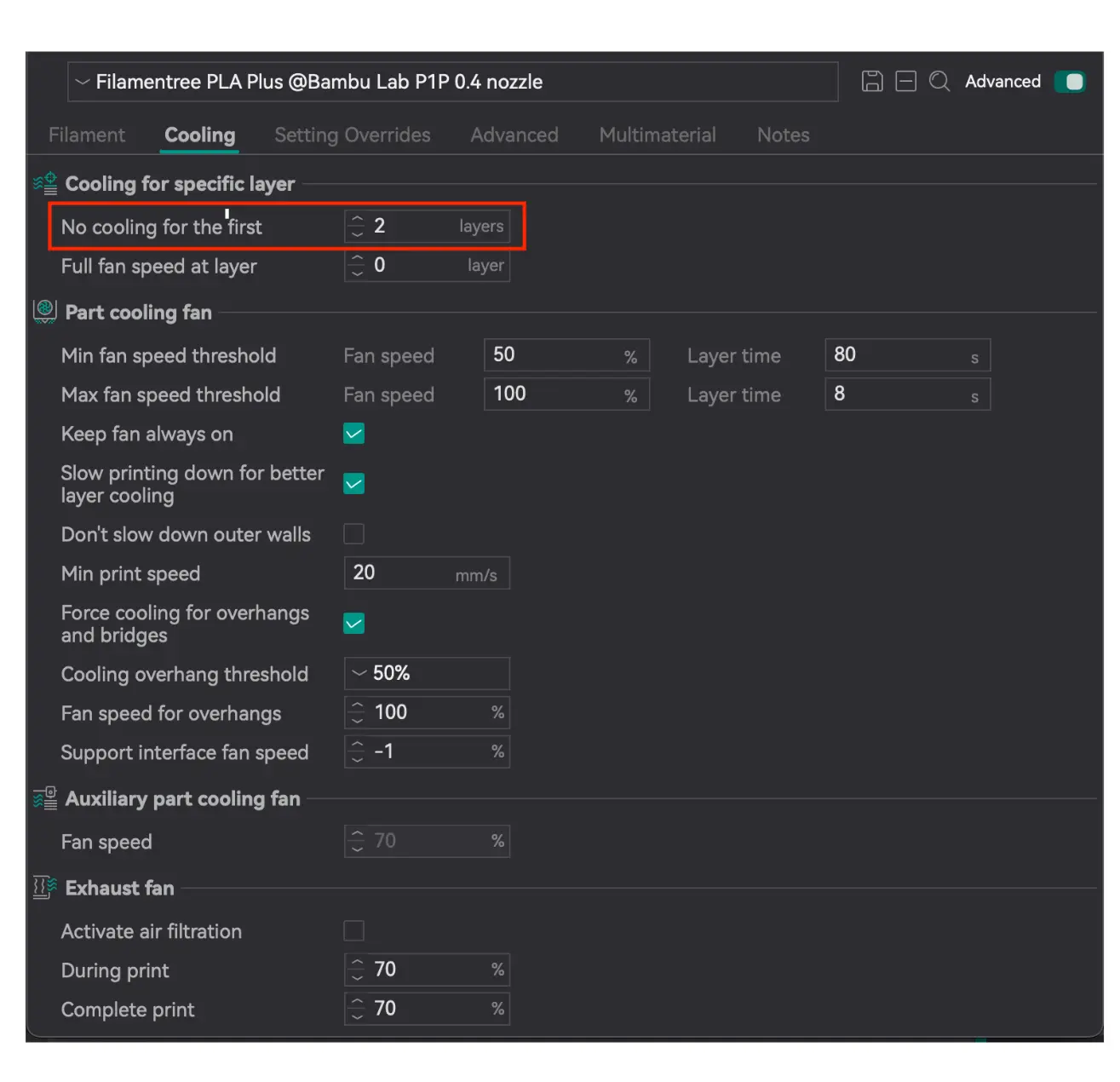

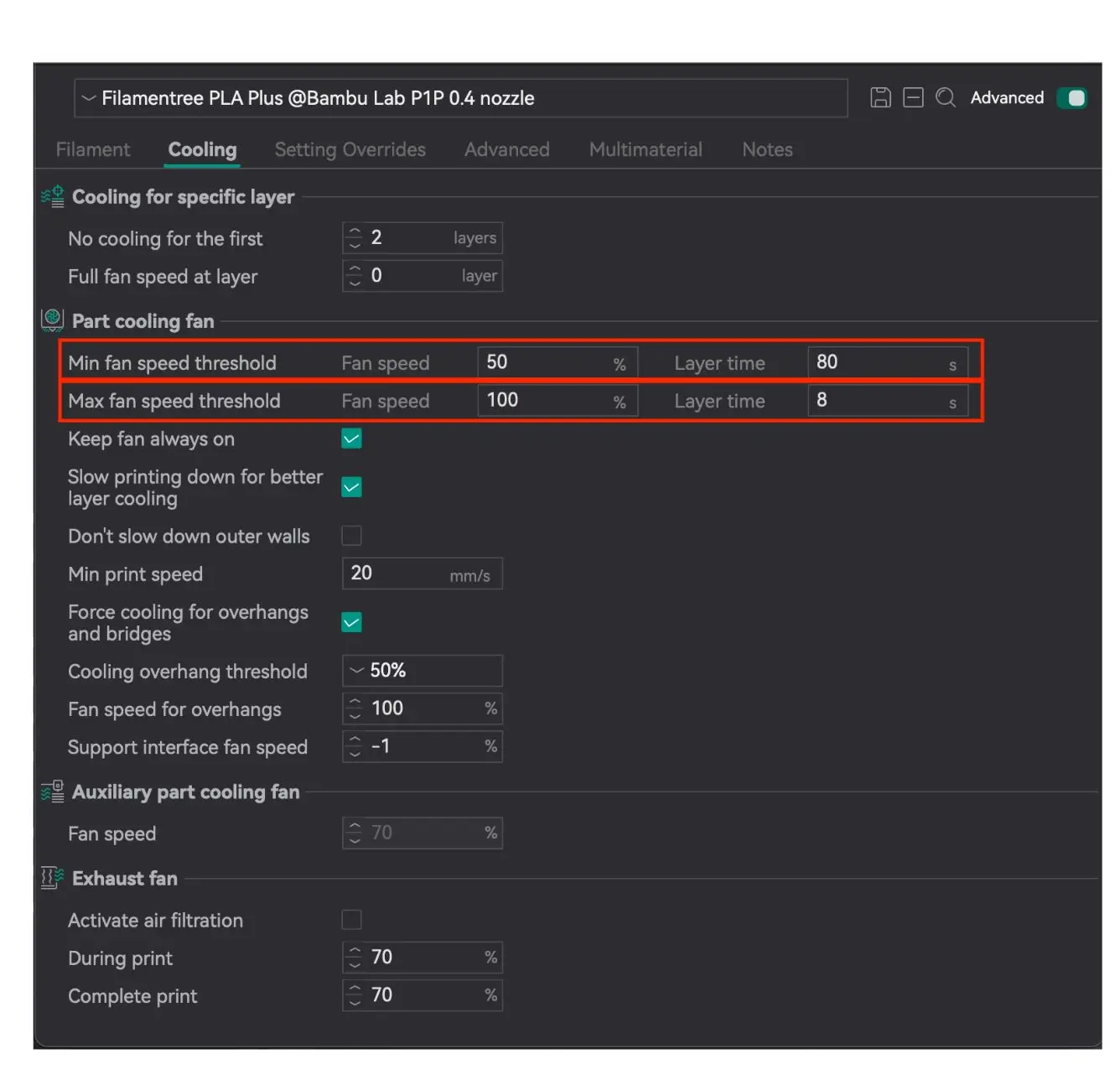

PLA Plus (PLA+) is an improved version of classic PLA, offering higher strength, better flexibility, and increased durability. To achieve the best printing results, it is essential to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

Using the correct printing parameters for PLA Plus is critically important for achieving high-quality results. PLA Plus, as an improved version of standard PLA, requires precise settings to optimize its properties. Following the recommended settings allows you to fully leverage the benefits of PLA Plus, ensuring strong, aesthetically appealing, and durable prints.