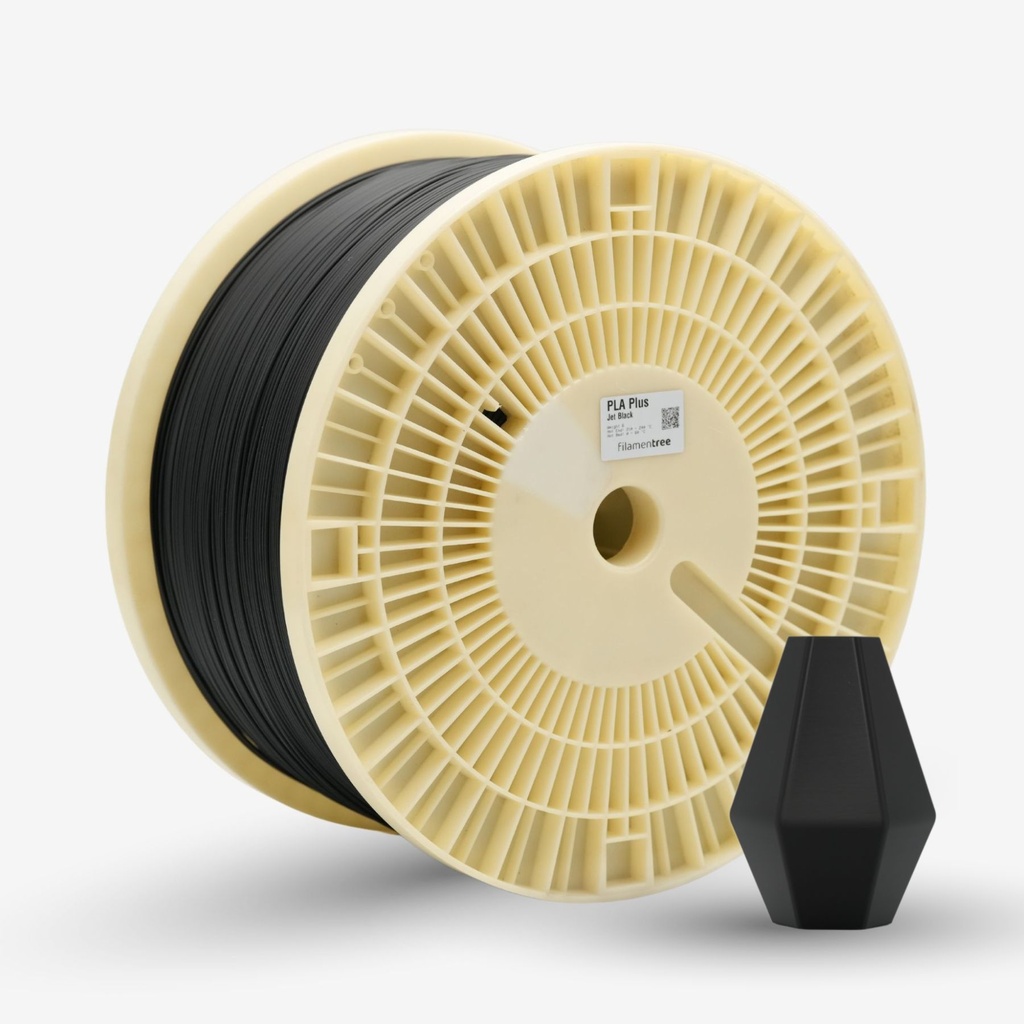

PLA Pro 6kg with Returnable Spool

Product Description:

PLA Pro 6kg with Returnable Spool is a high-performance 3D printing filament designed for users who demand enhanced strength, durability, and print quality while maintaining an eco-friendly approach. Made from premium-grade Polylactic Acid (PLA) with advanced additives, this filament offers greater impact resistance, higher heat tolerance, and improved mechanical properties compared to standard PLA.

The 6kg spool is perfect for large-scale or high-volume printing, ensuring fewer filament changes and consistent performance throughout long print jobs. Additionally, the returnable spool program allows you to send back the empty spool, helping to reduce plastic waste and support sustainable 3D printing practices.

Key Features:

- Advanced PLA Pro Formula: Improved strength, heat resistance, and impact durability compared to standard PLA.

- Large 6kg Spool: Ideal for continuous printing, reducing the need for frequent spool swaps.

- Returnable Spool Program: Minimize waste by returning the empty spool for reuse, promoting a sustainable printing solution.

- Excellent Printability: Easy to print with minimal warping, strong layer adhesion, and smooth extrusion.

- High Dimensional Accuracy: Consistent filament diameter ensures reliable performance and uniform prints.

- Low Odor & Environmentally Friendly: Made from bio-based materials, with low emissions for safe indoor use.

Applications:

- Functional and mechanical parts requiring extra strength and durability

- Prototyping for industrial and engineering purposes

- Large-format 3D prints with extended print times

- Architectural and artistic models

- Batch production of high-volume prints

- Educational and research applications

Safety Information:

- Use in a well-ventilated area.

- Keep out of reach of children.

- Store in a cool, dry place, away from direct sunlight and moisture.

PLA Pro 6kg with Returnable Spool is the perfect choice for professional and large-scale printing needs, offering superior mechanical properties while supporting an eco-conscious printing environment. Whether you’re working on durable prototypes, functional parts, or artistic creations, this filament delivers exceptional performance with sustainability in mind.

Specifications

| Colour | Jet Black or Pure White or Window Grey |

| Weight | 6 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

| Printing Temperature | 240-280°C |

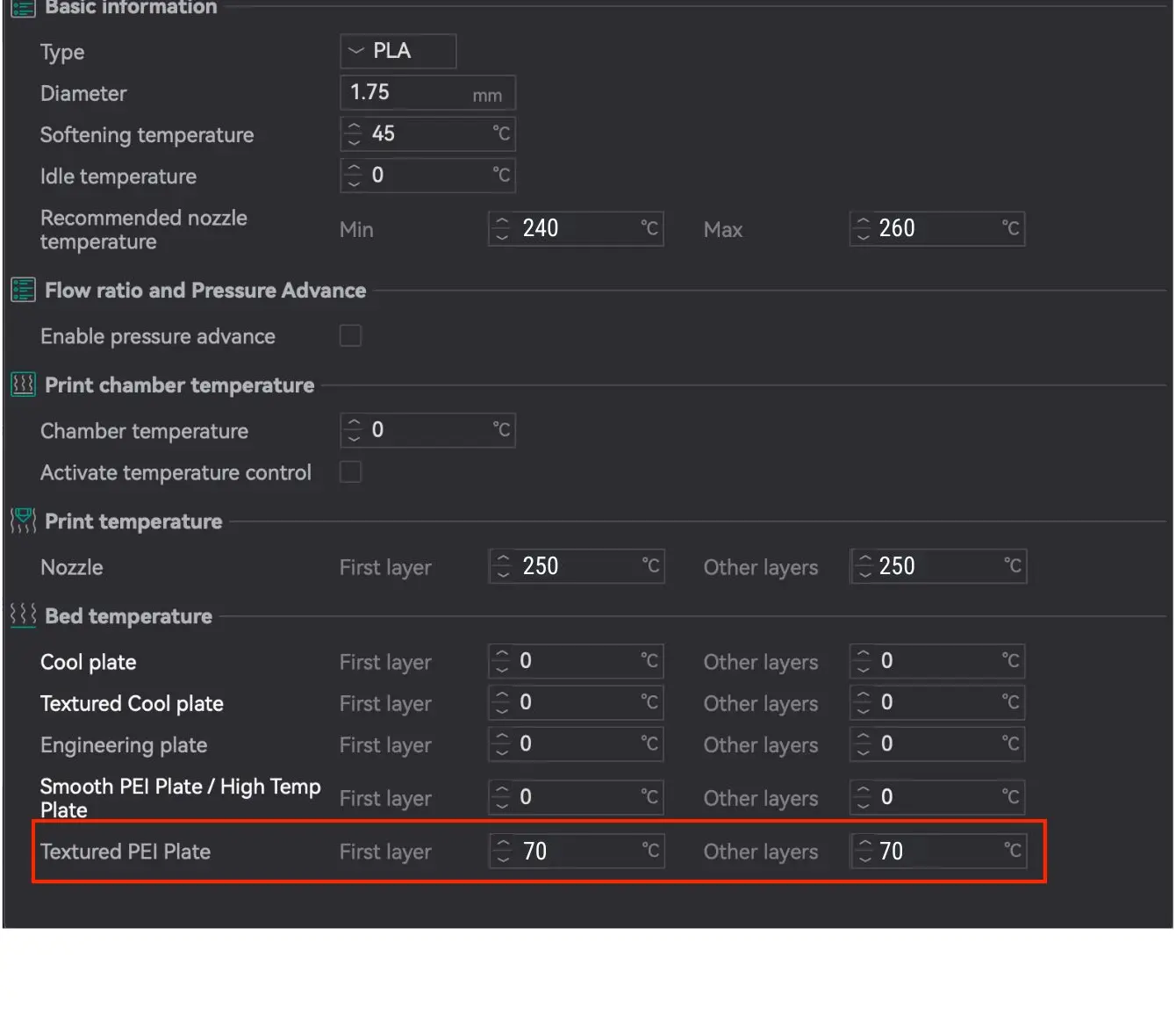

| Bed Temperature | 50°C – 80°C |

| Printing Speed | 40-500 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 90°C |

PLA Pro – Print Settings

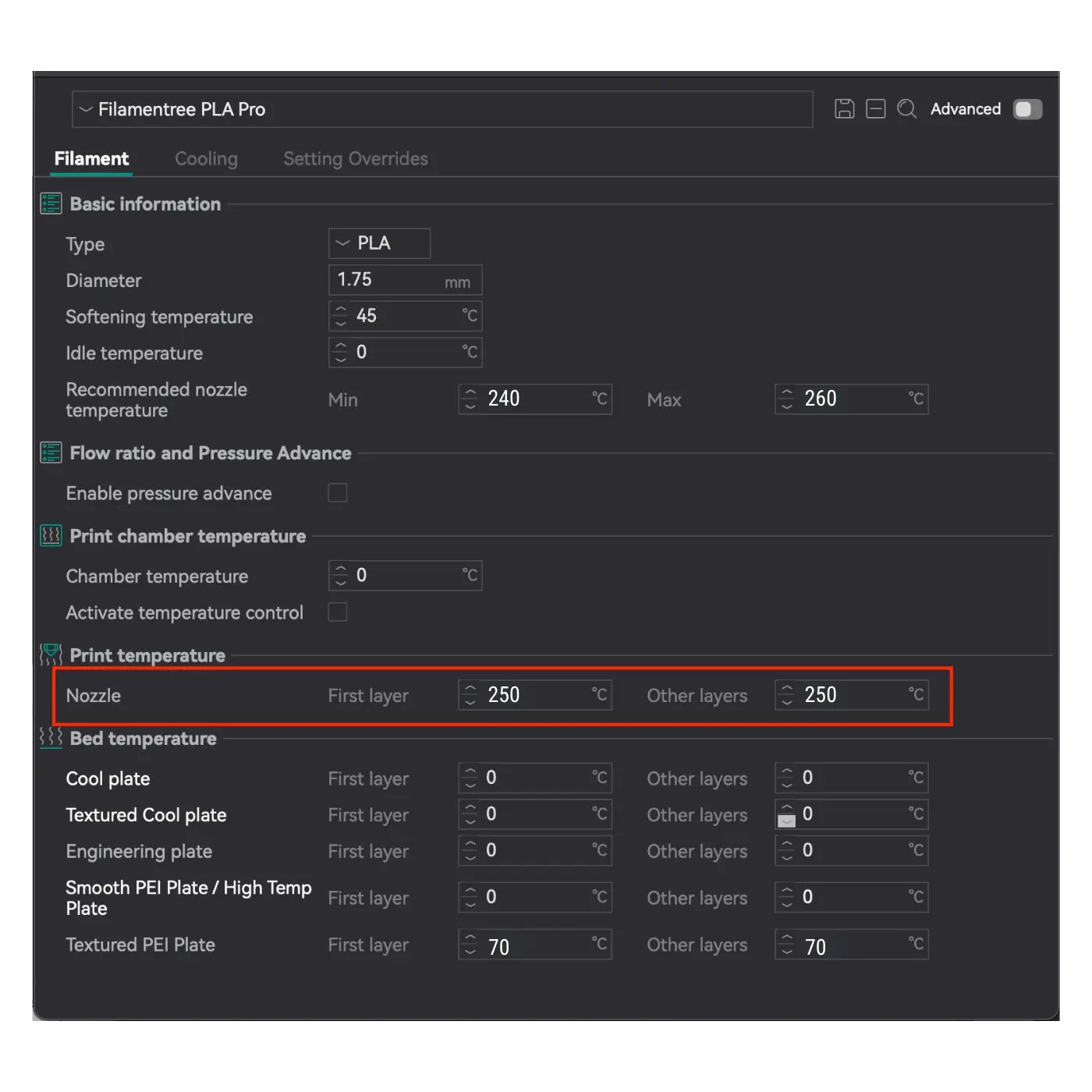

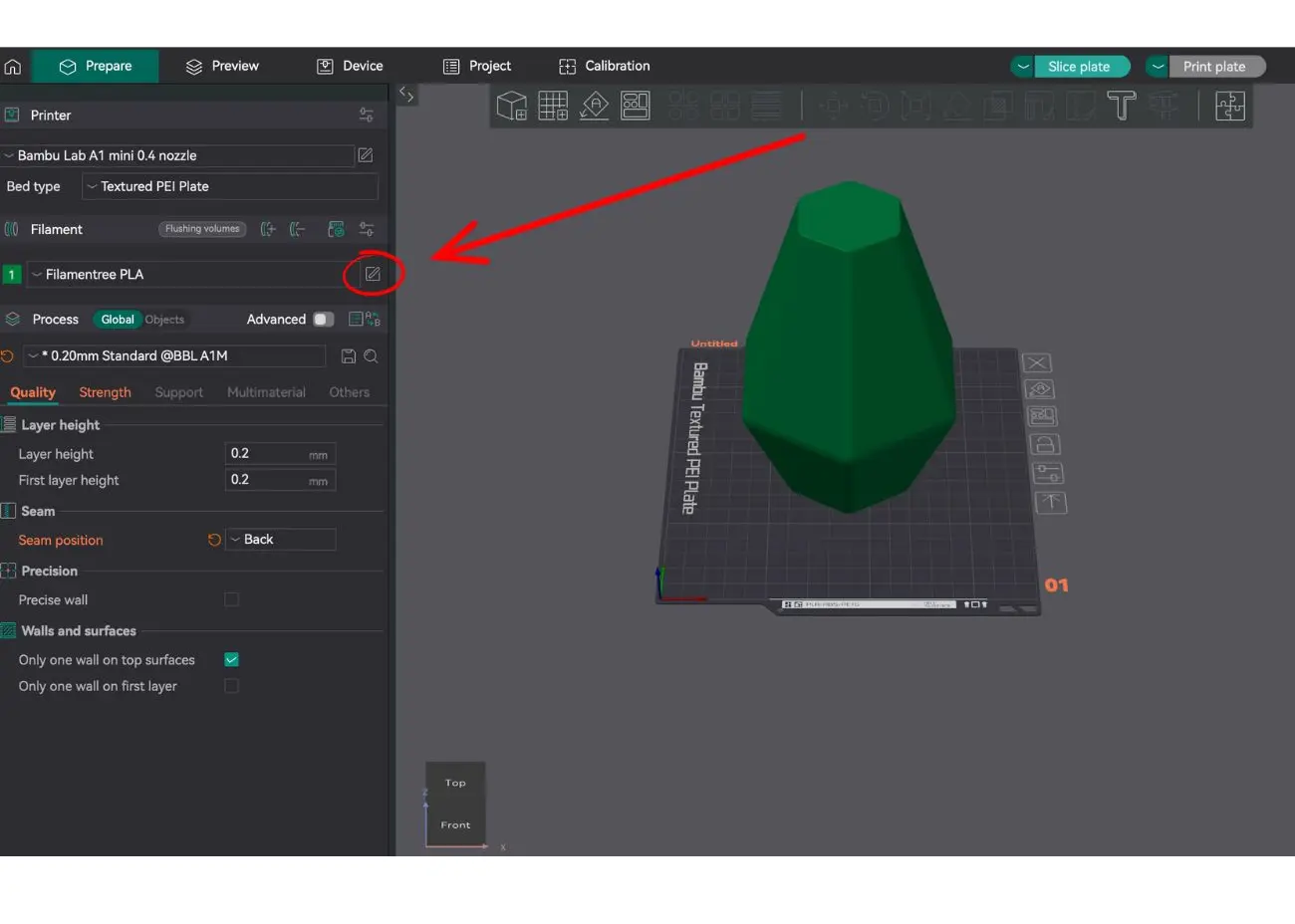

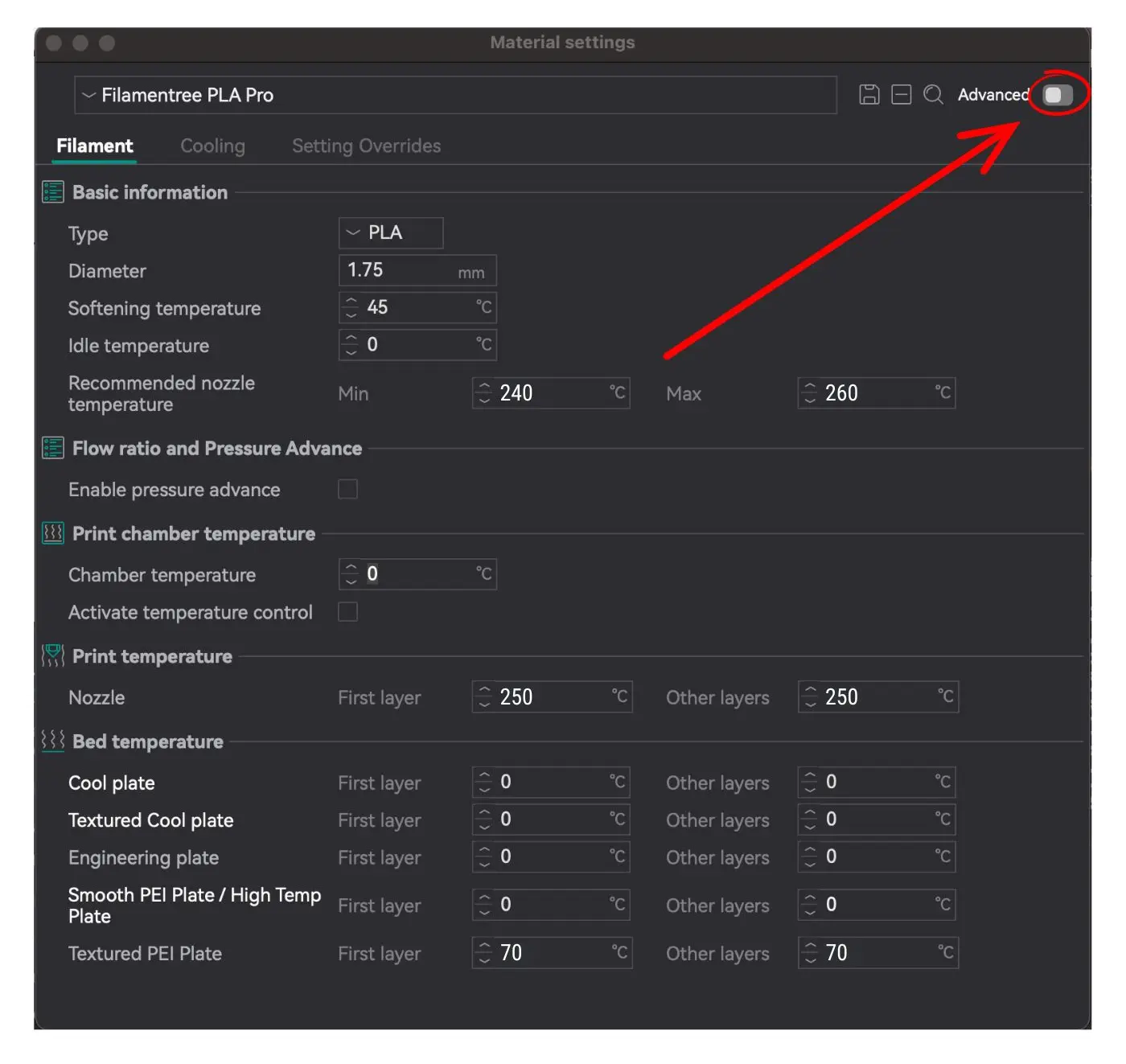

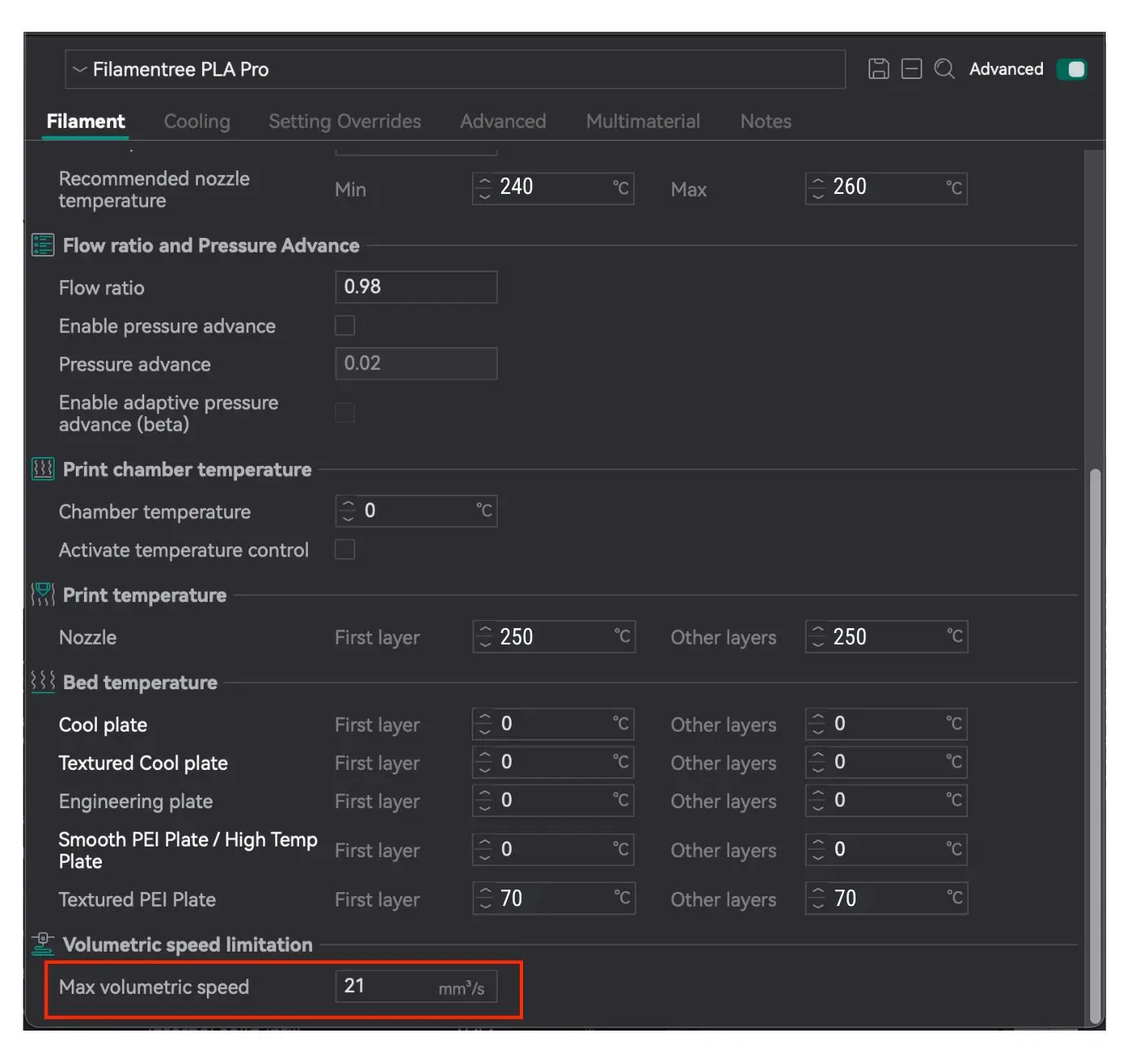

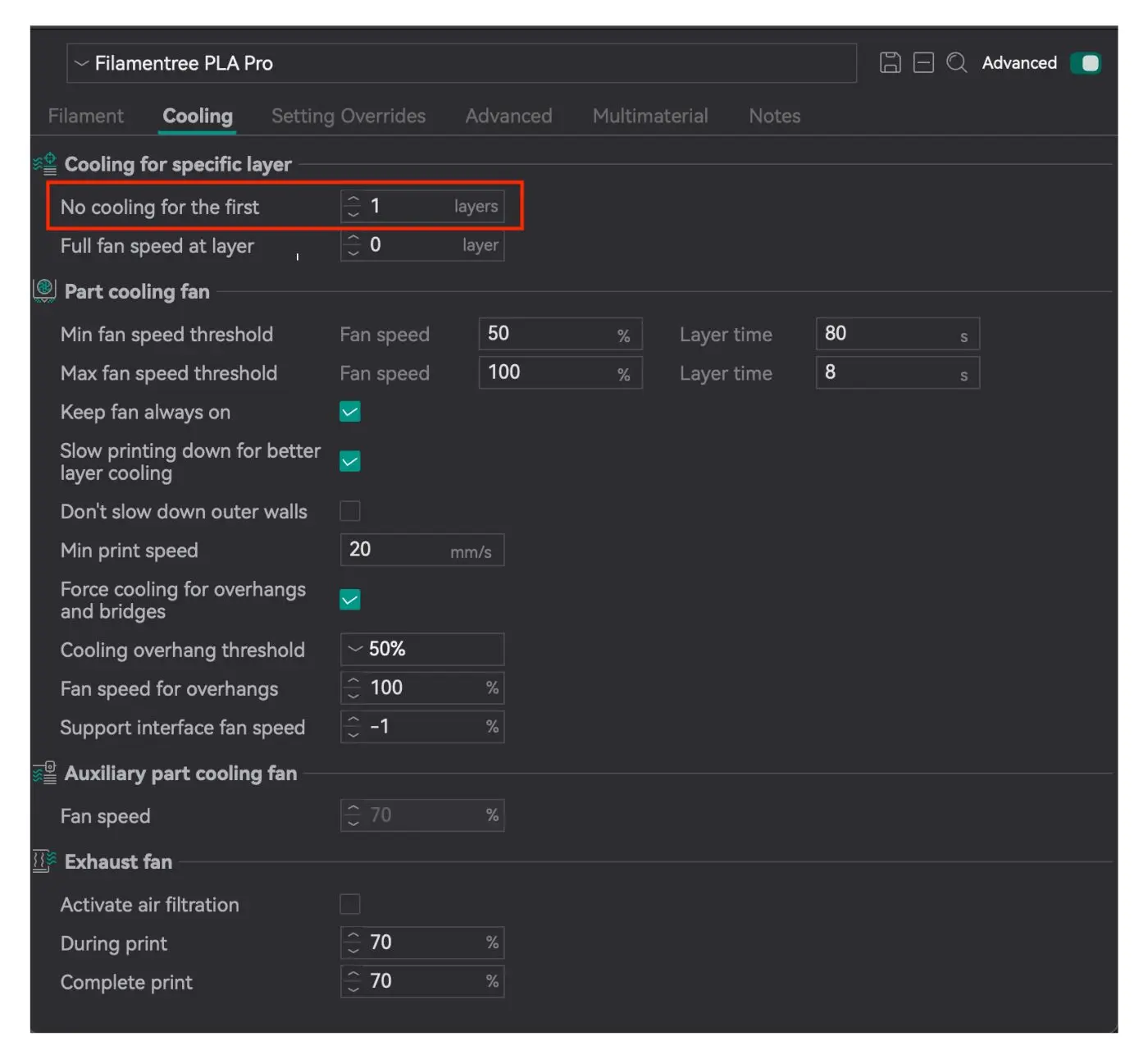

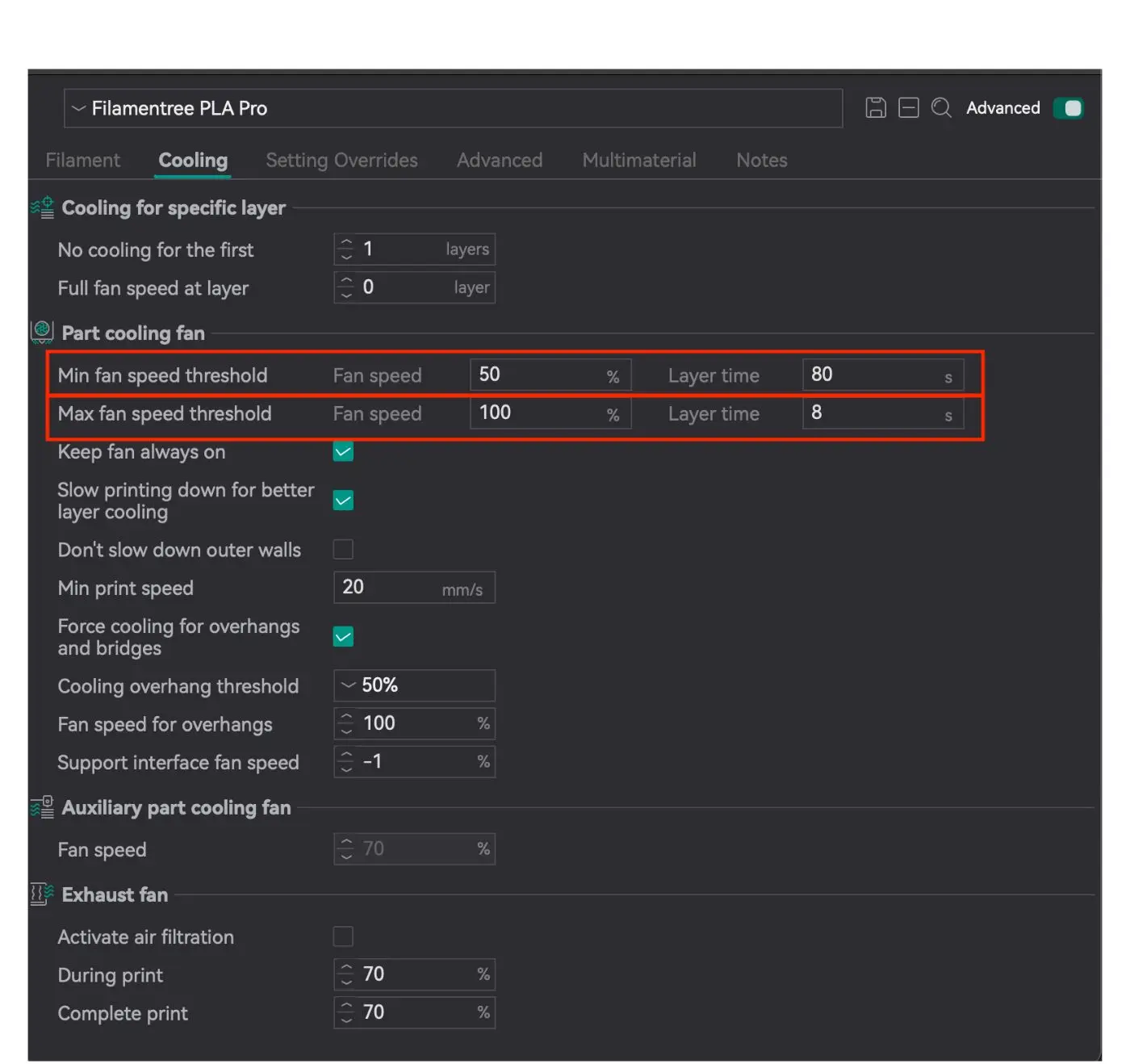

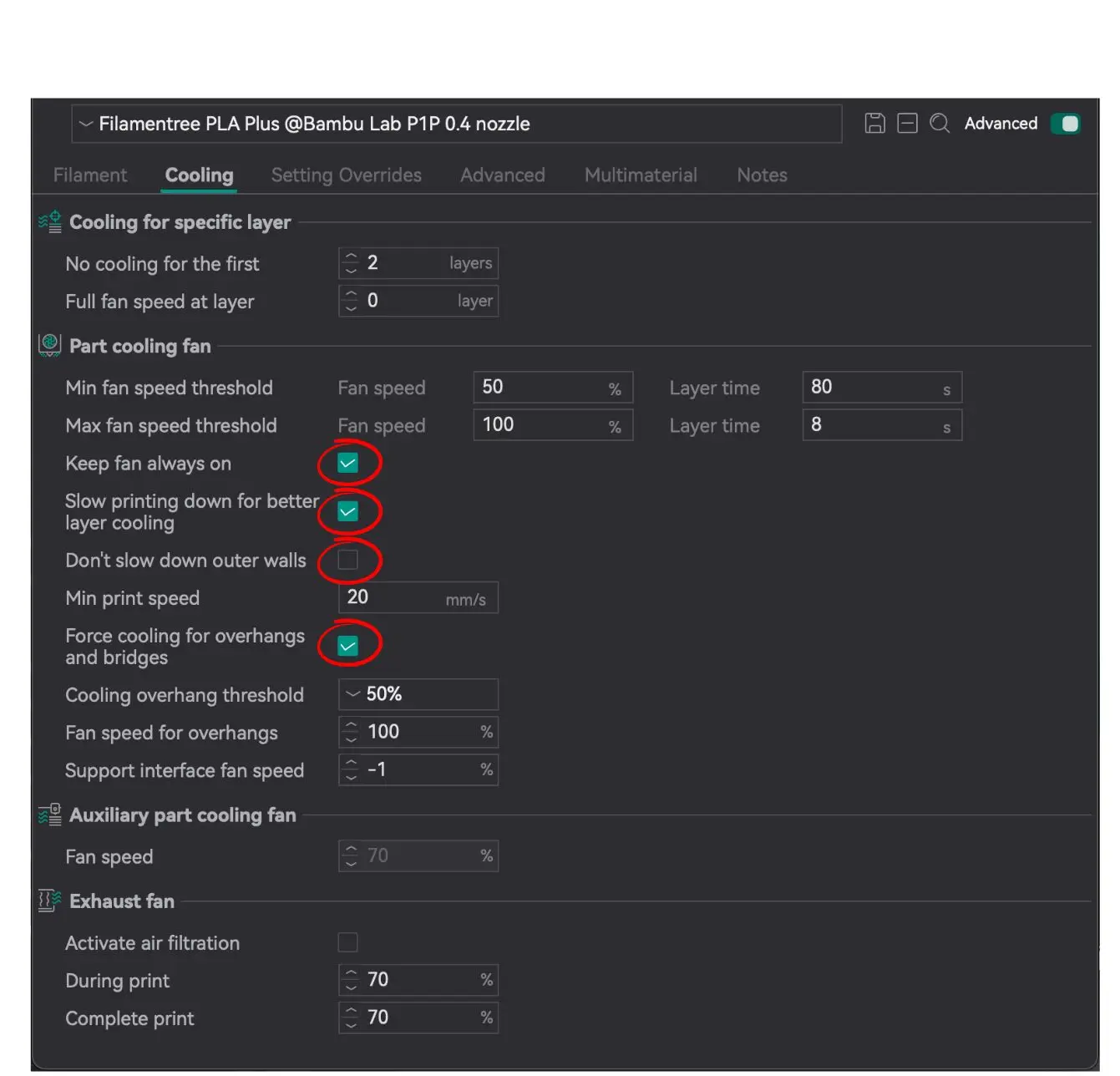

PLA Pro is an improved version of classic PLA, offering higher strength, better toughness, and increased heat resistance. This material is suitable for printing mechanically stressed parts while maintaining the ease of printing typical for PLA. To achieve optimal results, it is essential to set the printing parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

With the right slicer settings and optimized printing conditions, PLA Pro offers exceptional layer adhesion, increased impact resistance, and enhanced durability, making it a reliable choice for demanding 3D printing applications. Thanks to its improved mechanical properties, PLA Pro minimizes the risk of layer separation and ensures stable prints with sharp details and smooth surfaces. Proper cooling control, along with the correct print bed temperature, further enhances adhesion, reducing the chances of warping or model detachment.

By following these recommendations, you can achieve strong, high-quality 3D prints with PLA Pro, making it an excellent option for functional prototypes, mechanical parts, and high-detail models that require extra strength and stability.