Precise Diameter – The Foundation of Reliable Printing!

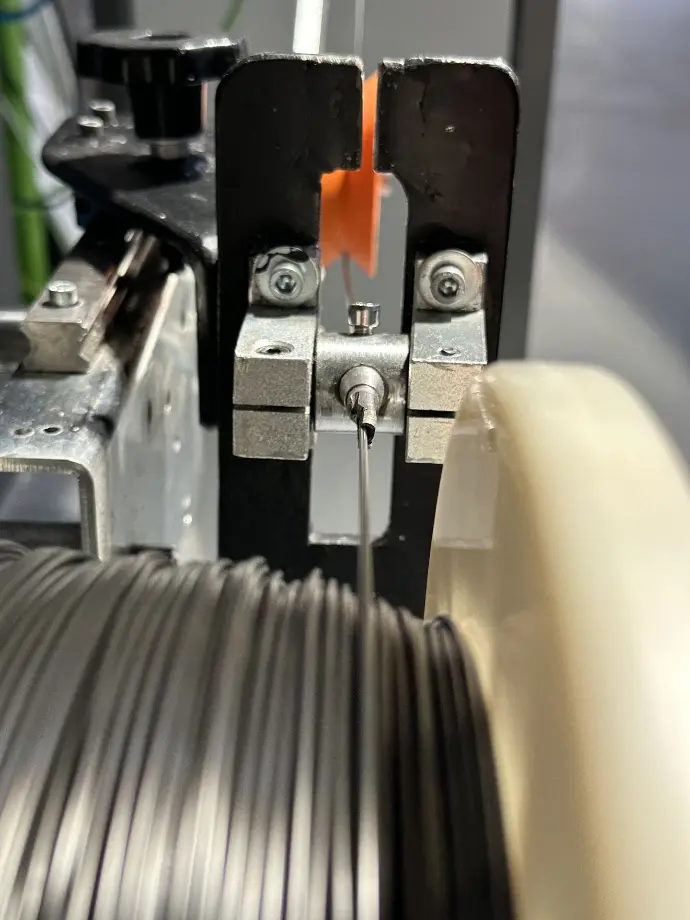

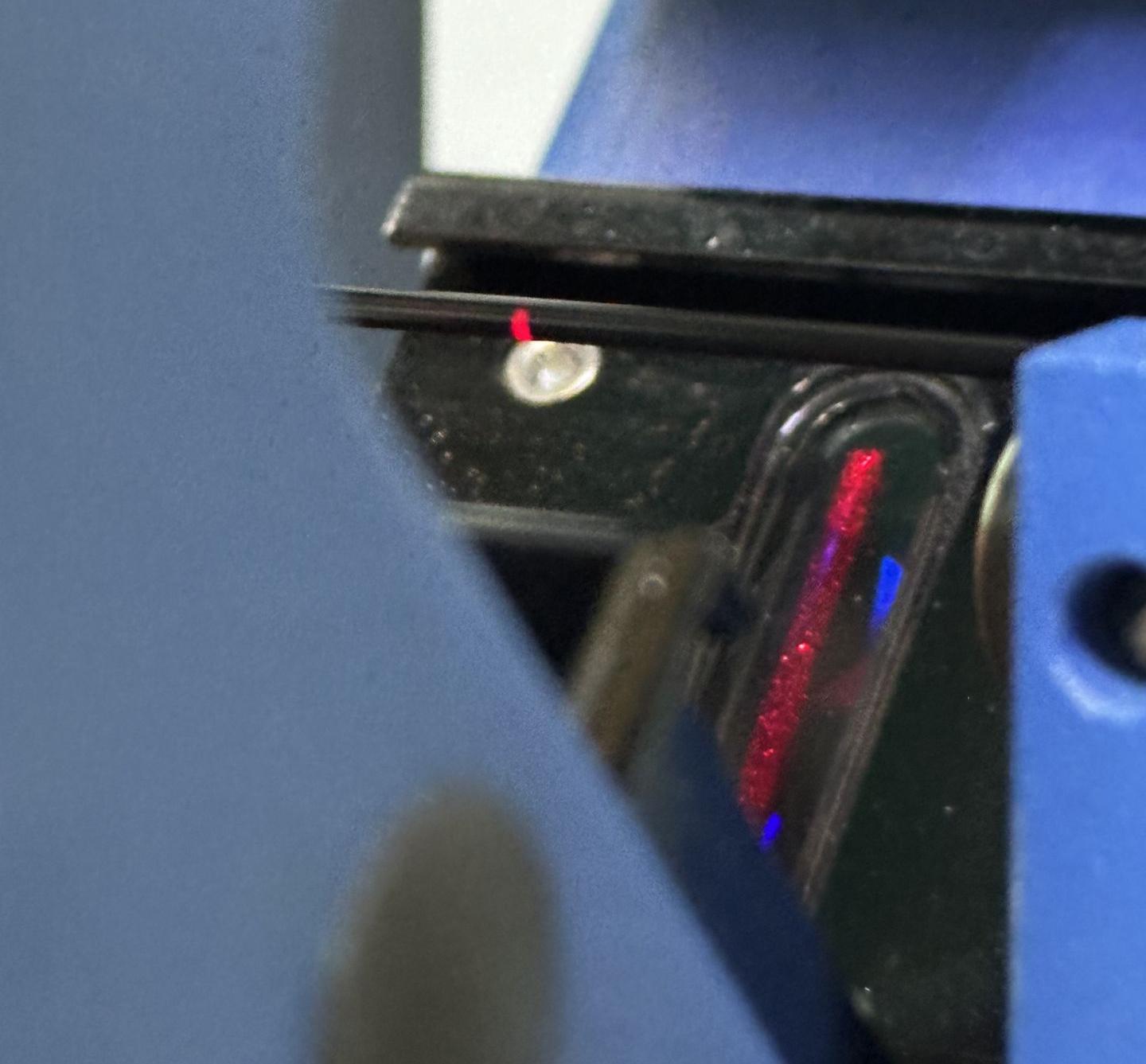

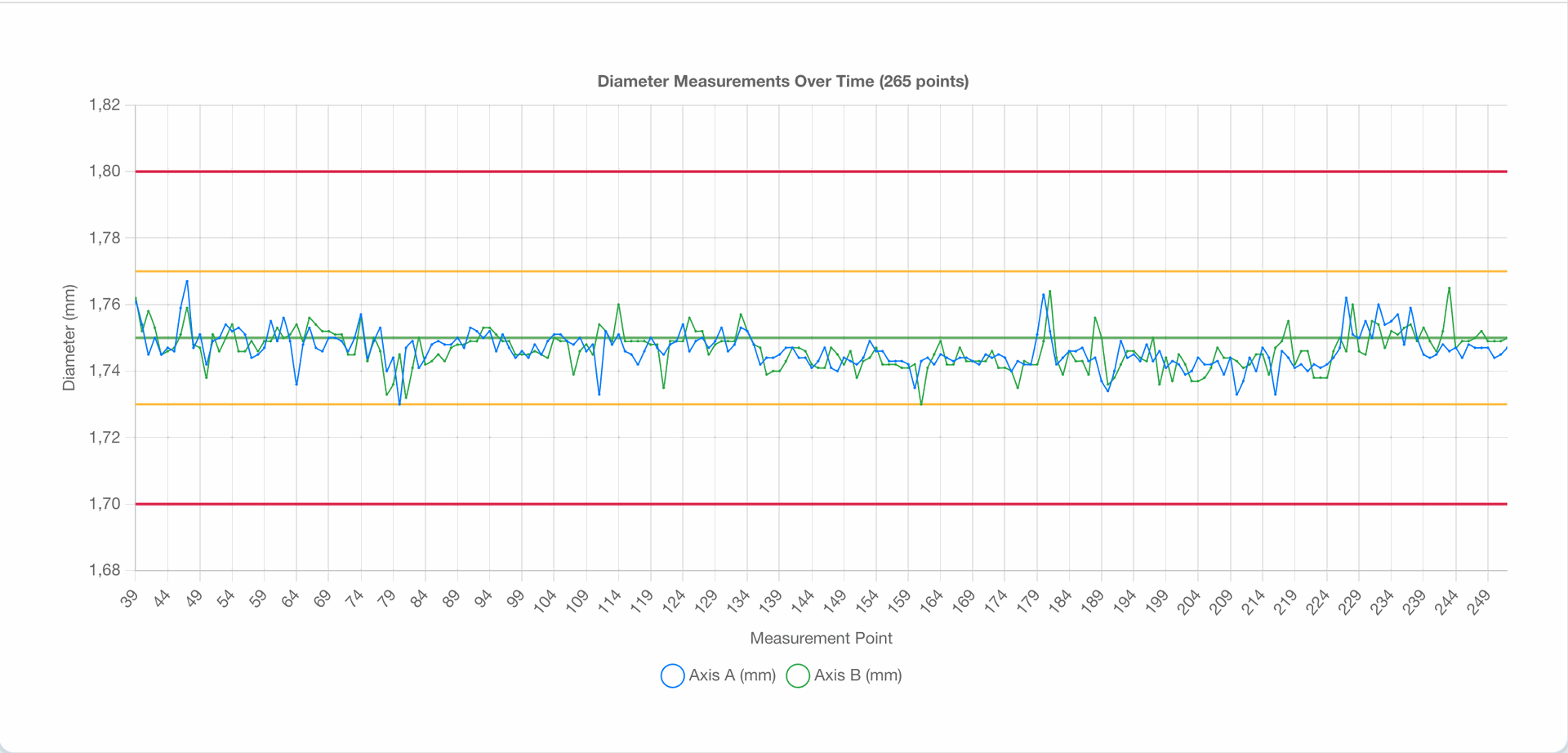

Every filament that leaves the extruder immediately passes through a dual-axis laser diameter gauge. This precise system checks the filament thickness every 30 milliseconds – meaning more than 30 measurements per second.

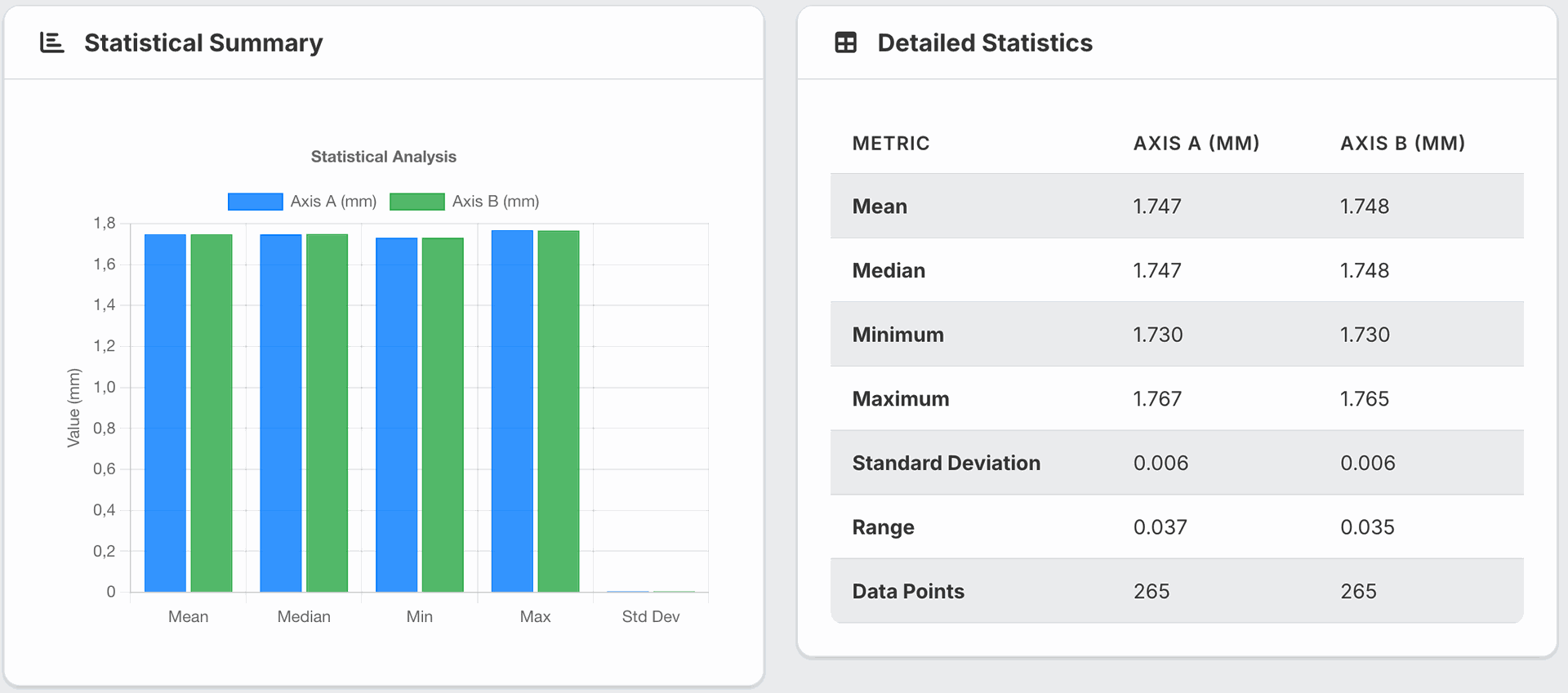

For PLA+ filaments, we maintain a diameter of 1.75 mm with an accuracy of ±0.02 mm, while for PETG the tolerance is ±0.03 mm. For special types, such as Carbon Fiber or Woodfill, the allowed deviation is ±0.05 mm.

This achieved precision ensures a smooth printing process and protects the nozzle from clogging, contributing to the reliability and consistency of every print.

Automatic Quality Sorting

Our system instantly decides whether the filament meets the strict criteria for first-class quality.

If a deviation is detected, the spool is automatically classified as second-class.

This way, you can always be sure that when you have a filament labeled as “first-class,” it truly is top quality.

Every Spool Carries Its Own Story: