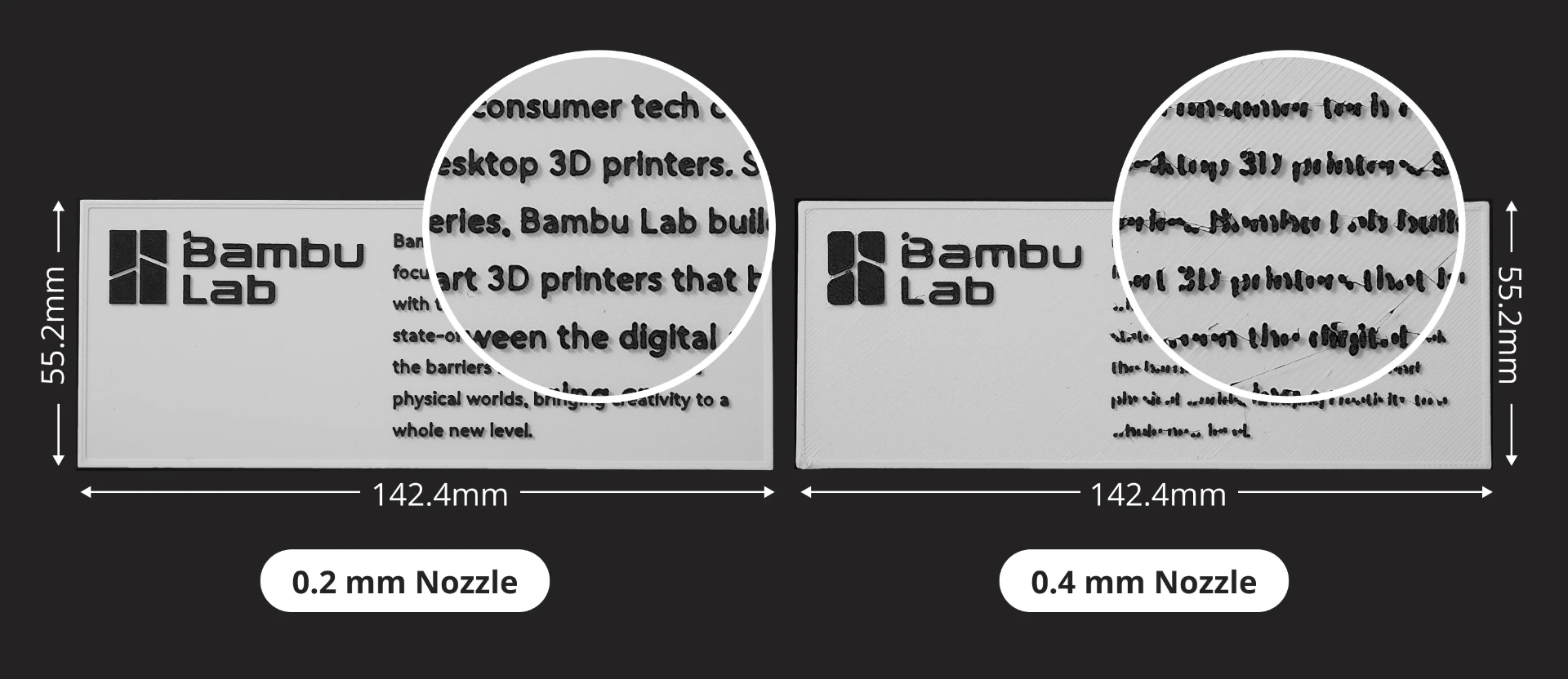

0.2mm Nozzle - Optimal Print Fineness

Smaller diameter extrudes thin filaments

High resolution on the horizontal print surface

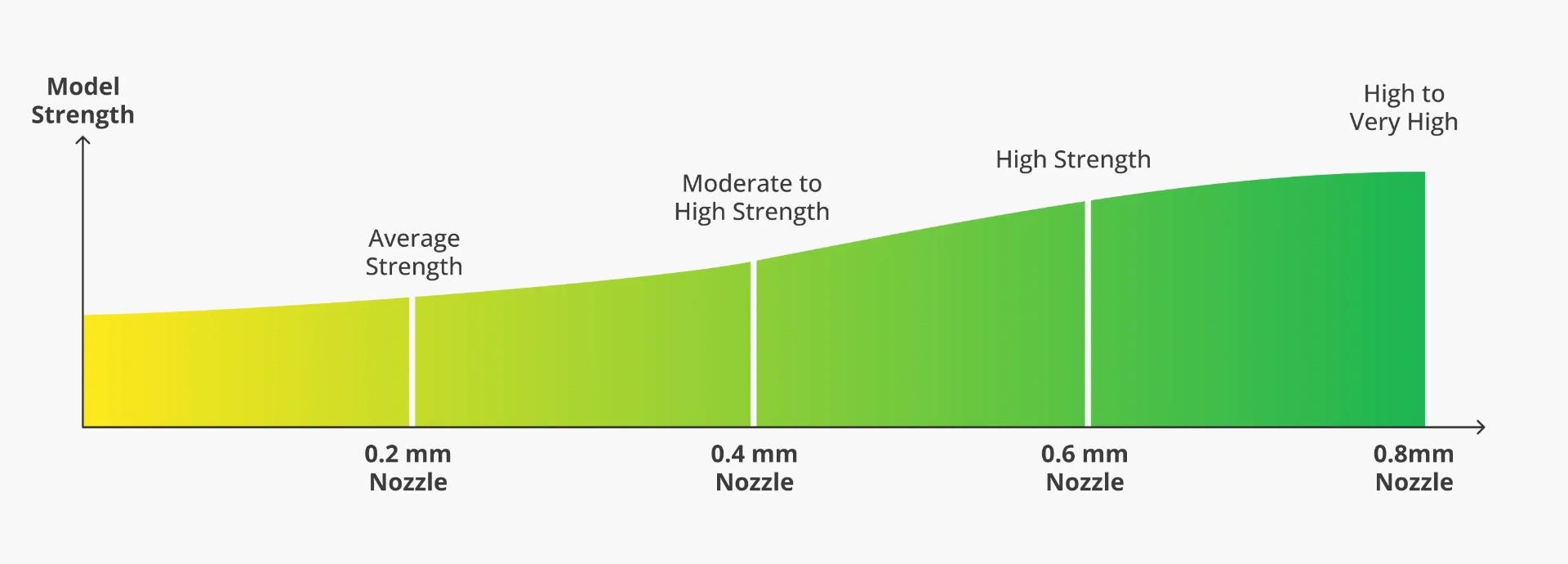

0.6mm and 0.8mm Nozzle - Faster Print Speed

Larger diameter extrudes more filaments per second, resulting in faster print speed

Comparison of Different Nozzle Sizes

| 0.2 mm Nozzle | 0.4 mm Nozzle | 0.6 mm Nozzle | 0.8 mm Nozzle | |

| Usage scenario | Perfect for small and intricate models, with precision that’s worth the wait |

Ideal for everyday use with the perfect balance of speed and qualty |

Faster speeds and capable of printing high-performance filaments, with some decrease in resolution |

Faster speeds and capable of printing high-performance filaments, with some decrease in resolution |

| Commonly used for | Miniature models Intricate logos Text Molds |

Toys Mechanical parts Decorative objects |

Large structural parts Functional parts for household Industrial or engineering parts High-strength models |

Large structural parts Functional parts for household Industrial or engineering parts High-strength models |

*The final display of 'Model Strength' & 'Model Fineness' depend on the results of the material testing

- Filaments with carbon fiber, glass fiber, metal, or other inorganic particles are prone to clog a 0.2 mm nozzle.

- For filaments containing carbon fiber or glass fiber, it is highly recommended to use a hardened steel 0.6 mm nozzle to minimize the risk of clogging and abrasion.

- PLA-CF and PETG-CF have been extensively tested and proven to have a low risk of clogging when printed with a hardened steel 0.4 mm nozzle, while also achieving higher print quality.

Product Specifications

| Max. Printing Temp. | 320 ℃ | Length | 47.3 mm |

| Packaging Weight | 30 g | Packaging Size | 60*60*30 mm |

| Size | 0.2 mm or 0.4mm or 0.6mm |

| Brand | Bambu Lab |