PLA-CF Black 0.75kg (Carbon Fiber Reinforced) – Premium Engineering Filament for 3D Printing

PLA-CF

Black combines the ease of printing with PLA and the exceptional

strength of carbon fiber, creating a lightweight yet ultra-durable

filament for demanding applications. Designed for engineers, makers, and

professionals, this carbon fiber-reinforced PLA delivers unmatched

rigidity, dimensional stability, and a sleek matte-black finish, perfect

for high-performance parts that require precision and resilience.

Key Benefits:

- Carbon Fiber Reinforcement: 20% carbon fiber infusion boosts stiffness, reduces flex, and enhances wear resistance, ideal for structural components and functional prototypes.

- Lightweight & Strong: Maintains PLA’s ease of use while offering near-ABS-level strength, perfect for weight-sensitive applications like drones, automotive parts, or robotics.

- Matte Black Professional Finish: The refined, non-reflective surface adds a stealthy, industrial aesthetic to prints, suitable for professional or consumer-facing products.

- Dimensional Stability: Minimal warping and superior layer adhesion ensure precise, repeatable prints even for complex geometries.

- Abrasion Resistance: Withstands friction and mechanical stress, making it ideal for gears, bearings, or moving parts.

Applications:

- Engineering & Robotics: Durable brackets, motor mounts, or robotic arms requiring stiffness and low weight.

- Automotive & Aerospace: Lightweight interior components, drone frames, or UAV parts demanding strength-to-weight ratios.

- Industrial Tooling: Jigs, fixtures, or custom tools that need rigidity and longevity.

- Consumer Products: High-end tech accessories, camera gear, or sports equipment with a premium finish.

- Prototyping: Functional prototypes that mimic the performance of production-grade materials.

Ideal For:

- Engineers and designers prioritizing strength, stiffness, and lightweight performance.

- Applications where traditional PLA lacks durability, but metal or ABS is impractical.

- Users seeking a professional, matte-black finish for industrial or consumer products.

- High-stress environments requiring abrasion resistance and dimensional accuracy.

PLA-CF Black redefines the limits of desktop 3D printing, merging the accessibility of PLA with the elite performance of carbon fiber. Elevate your projects with a filament built for innovation and endurance.

| Colour | Black |

| Weight | 1 kg |

| Diameter tolerance | < 0,03 mm |

| Diameter | 1,75 mm |

| Heat resistance | up to 90°C |

| Printing Temperature | 230-260°C |

| Bed Temperature | 50°C - 70°C |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

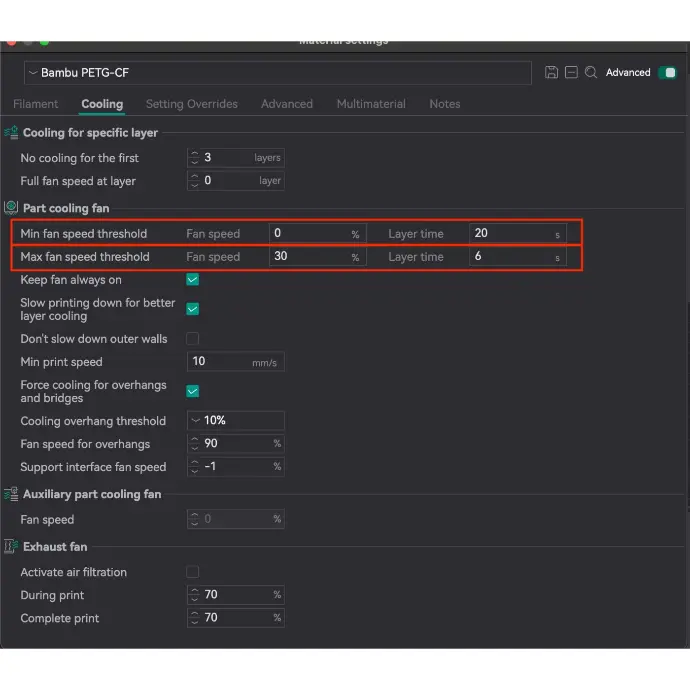

PLA-CF a PETG-CF – Print Settings

PLA-CF (Carbon Fiber PLA) and PETG-CF (Carbon Fiber PETG) are advanced 3D printing materials reinforced with carbon fiber, offering unique benefits for various applications. Both materials provide enhanced stiffness, reduced weight, and excellent dimensional stability, making them suitable for functional and structural parts.

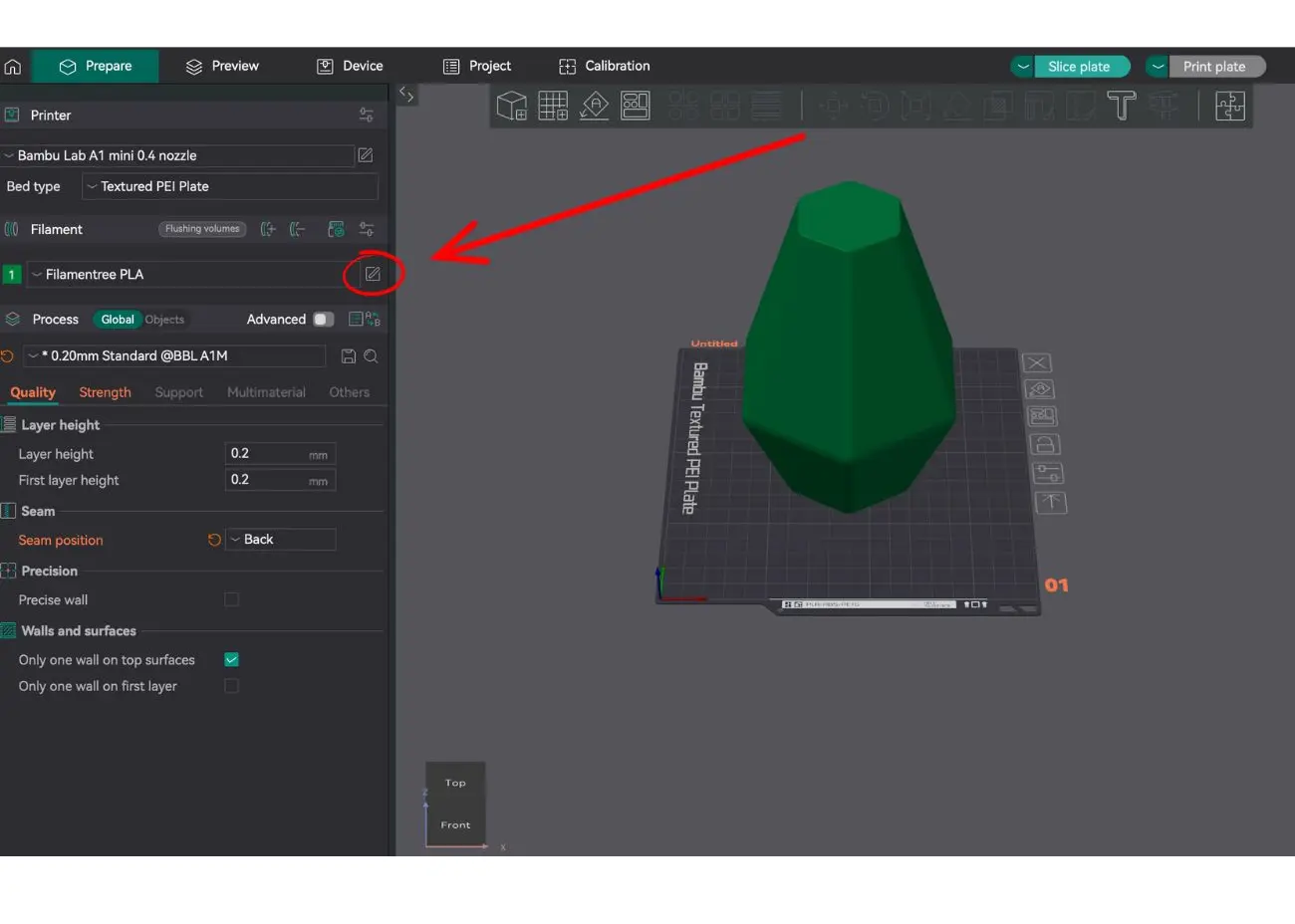

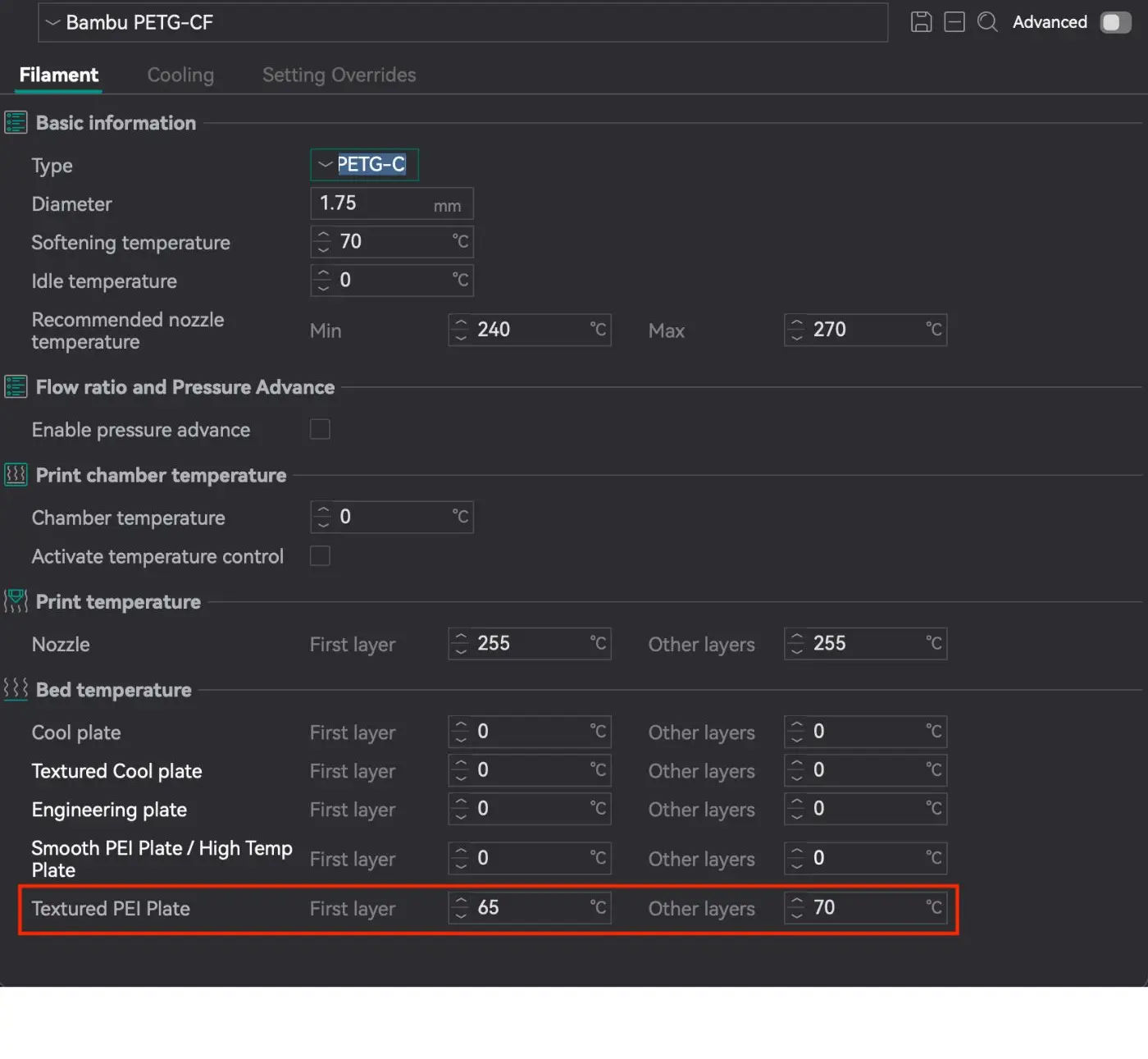

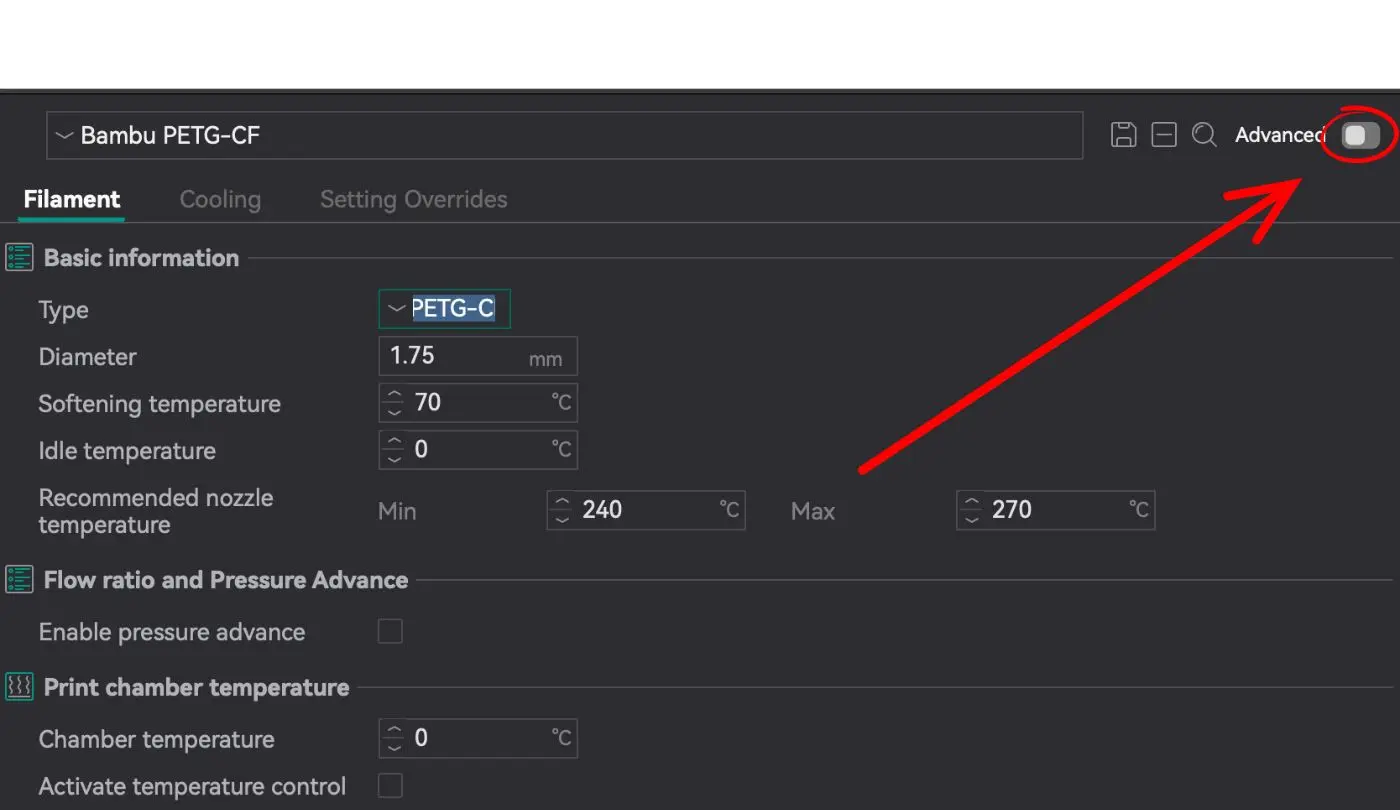

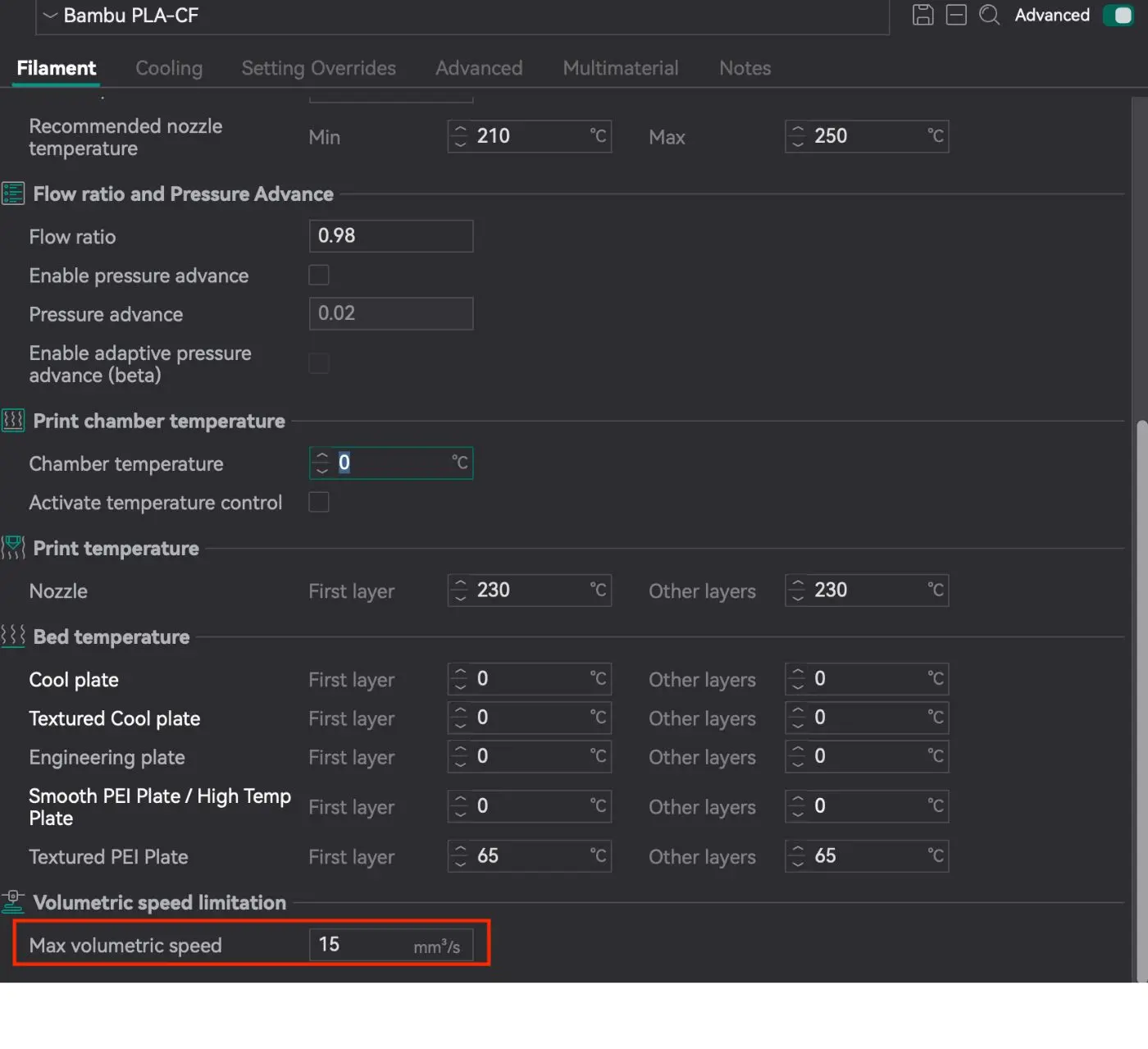

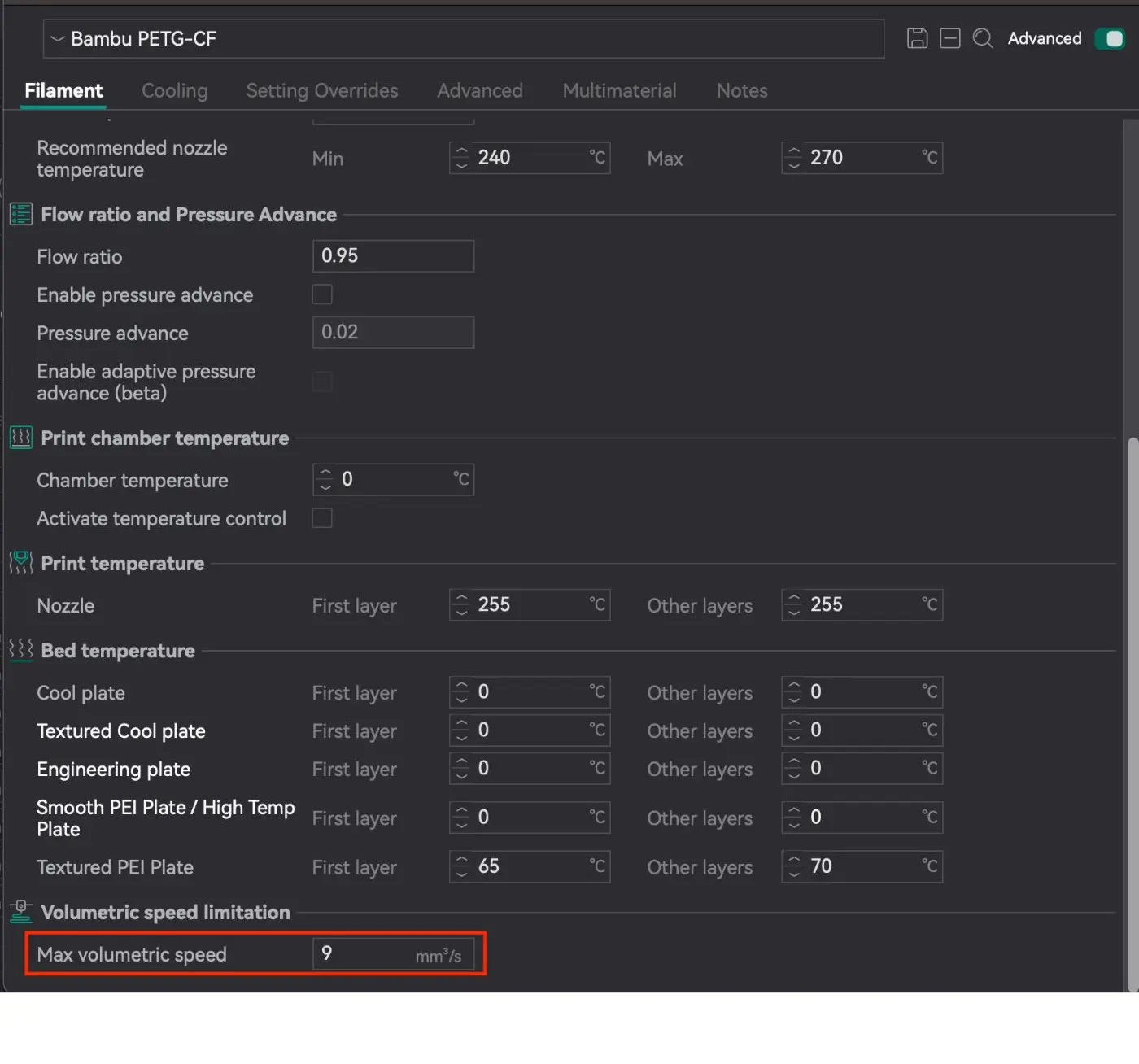

To achieve the best printing results, it is essential to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

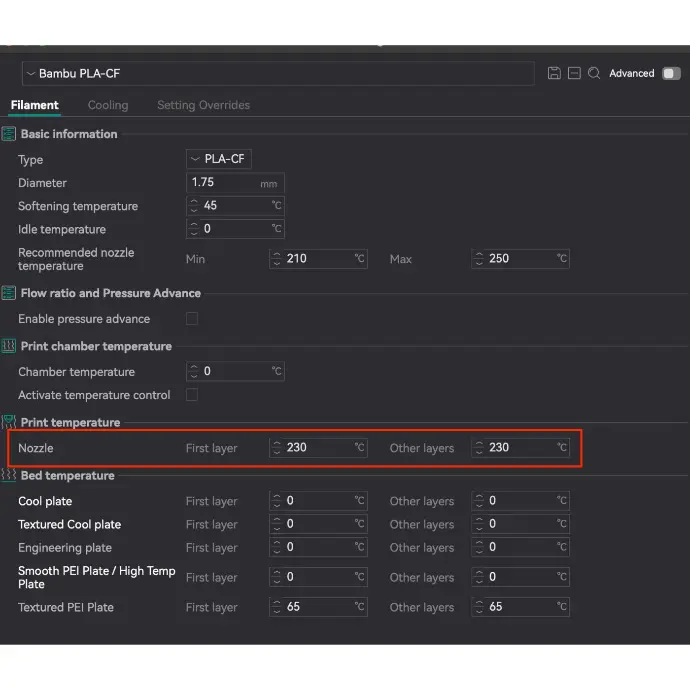

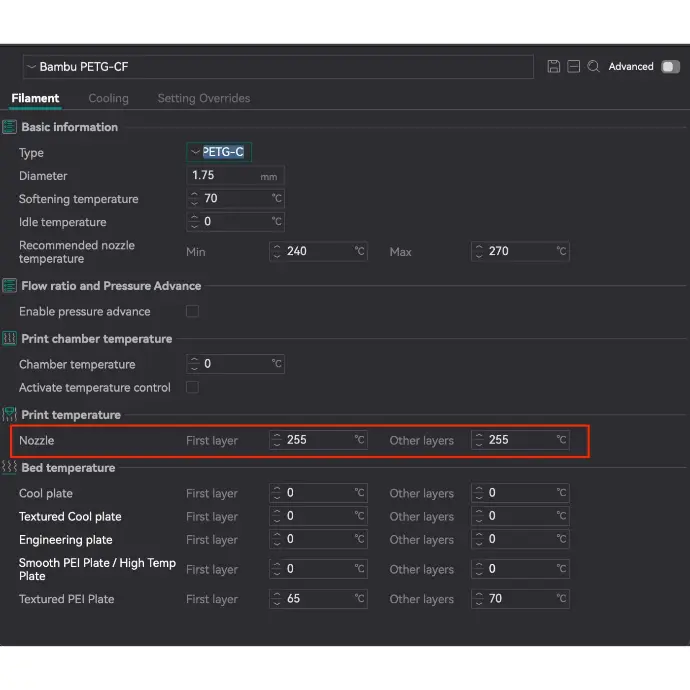

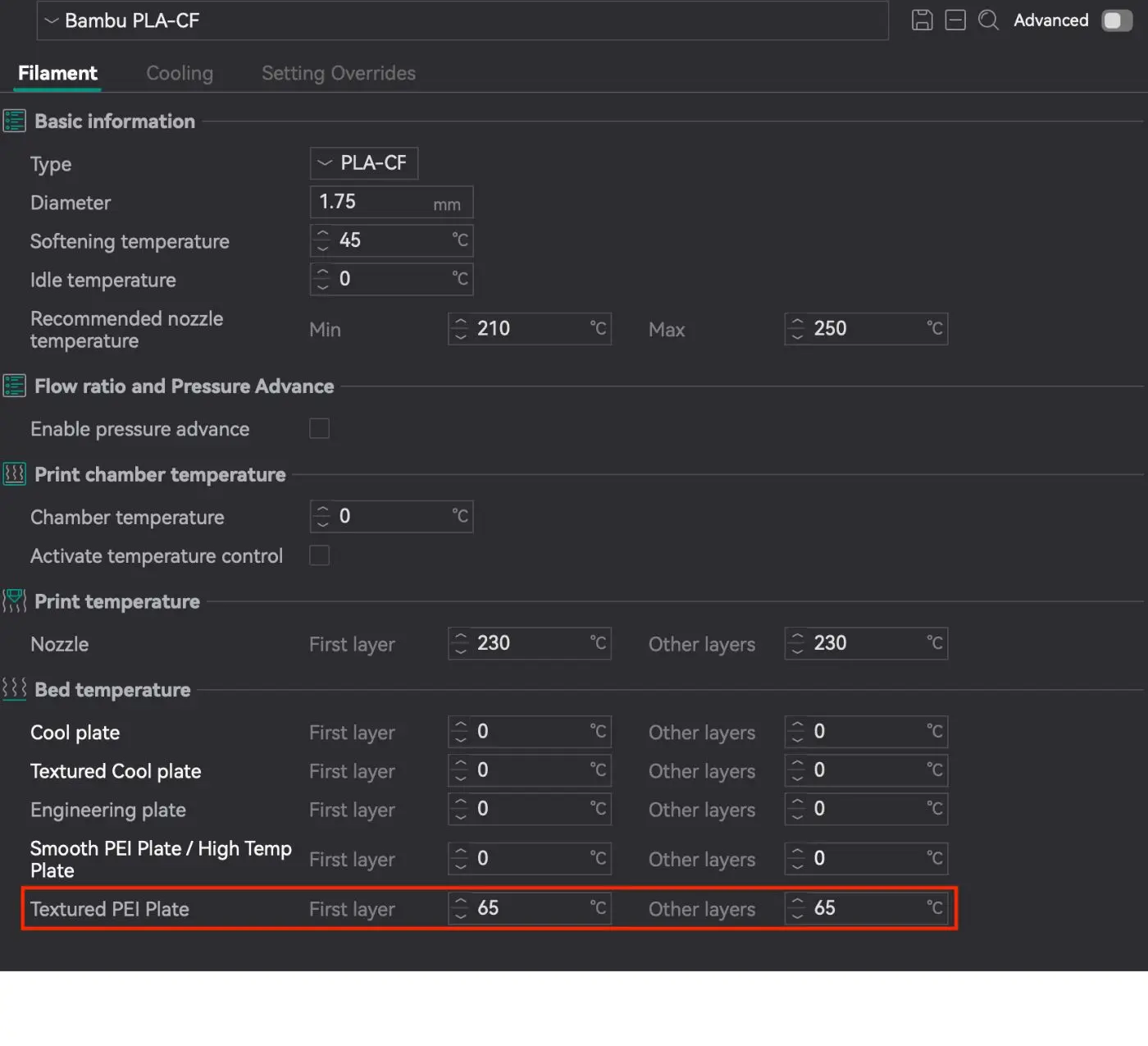

PLA-CF and PETG-CF require precise adjustments to temperature, cooling, and print speed to fully utilize their unique properties. Proper settings ensure high-quality, durable, and functional prints. Here’s why:

- Temperature Control: Higher nozzle and bed temperatures are essential to ensure proper melting, strong layer bonding, and prevent under-extrusion.

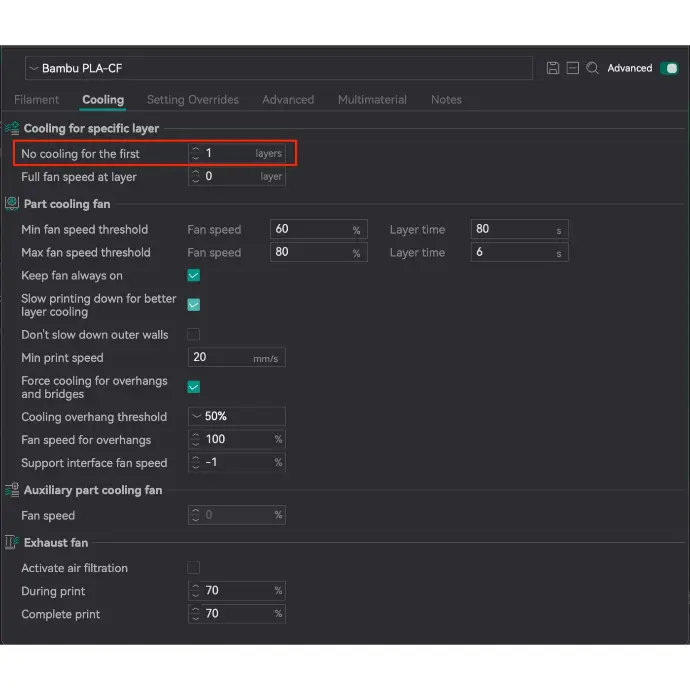

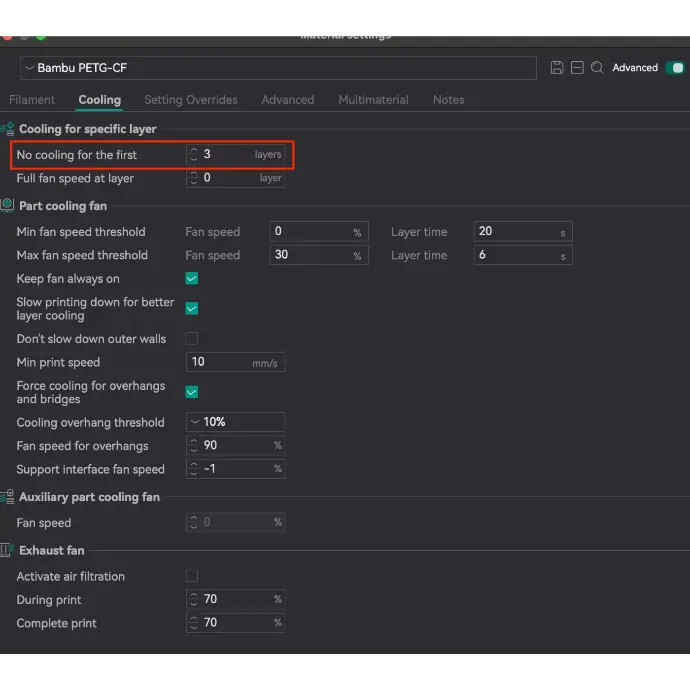

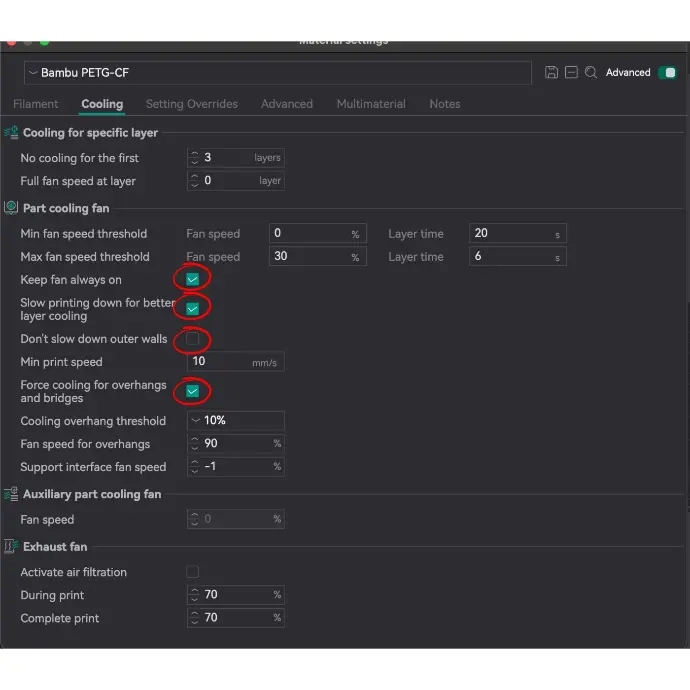

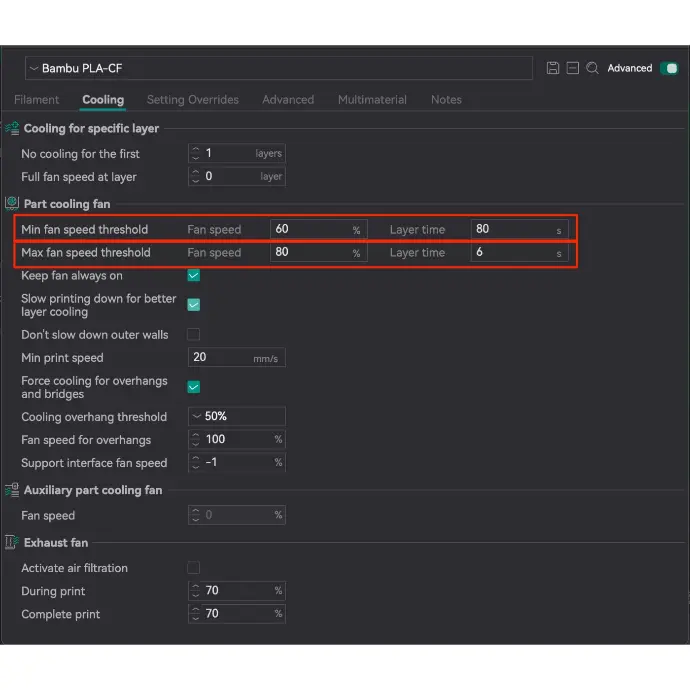

- Cooling Adjustments:

- PLA-CF: Moderate cooling prevents deformation and maintains dimensional accuracy.

- PETG-CF: Minimal cooling reduces warping and ensures strong layer adhesion.

- Print Speed Optimization: Slower speeds reduce strain on the extruder and improve extrusion consistency for stiffer, carbon fiber-reinforced materials.

By carefully tuning these parameters, you achieve precise, strong, and defect-free prints, making PLA-CF and PETG-CF ideal for functional and structural applications.