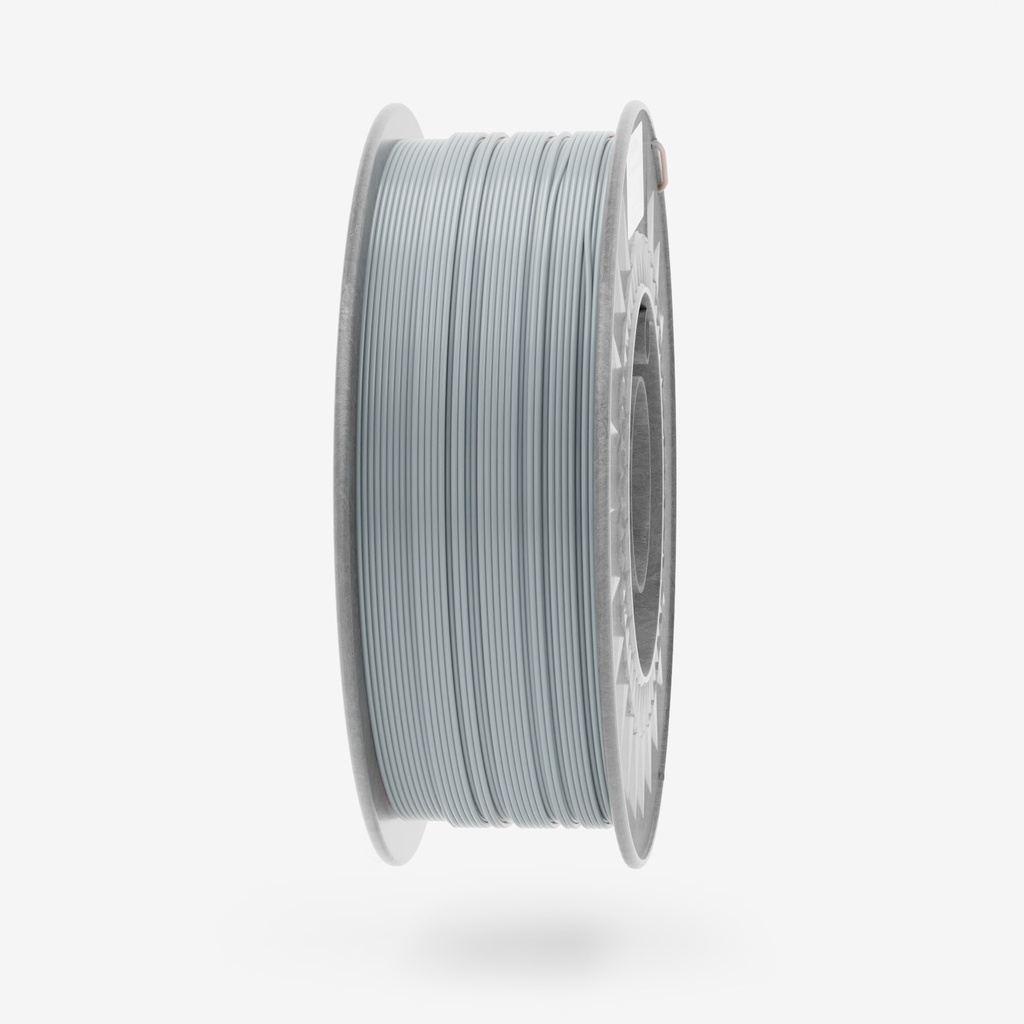

Product Description: PLA Pro Window Grey 1kg Filament

Elevate your 3D printing projects with PLA Pro Window Grey,

a premium-grade filament designed for professionals and enthusiasts

seeking precision, durability, and a touch of sophistication. This

translucent grey filament combines the eco-friendly benefits of PLA with

enhanced performance, making it ideal for functional and decorative

applications alike.

Key Features:

- Semi-Transparent Aesthetic: The unique "Window Grey" hue offers a sleek, modern appearance with a subtle translucency, perfect for mimicking glass or creating light-diffusing effects in lampshades, lanterns, or architectural models.

- Pro-Grade Performance: Enhanced layer adhesion, reduced warping, and improved thermal stability ensure smooth, reliable prints—even for complex designs.

- Eco-Conscious Material: Made from renewable, biodegradable resources (non-toxic, plant-based PLA), this filament supports sustainable creativity.

- Consistent Quality: Precision-engineered with a diameter tolerance of ±0.03mm for clog-free printing and flawless results.

- User-Friendly: Optimized for FDM printers, with low odor and minimal warping. Compatible with most desktop 3D printers.

Applications:

- Decorative Designs: Craft translucent vases, geometric art, or custom lighting fixtures.

- Functional Prototypes: Create enclosures, panels, or prototypes requiring a semi-transparent finish.

- Architectural Models: Simulate glass windows or modern structures with a professional touch.

- Educational & Hobby Projects: Ideal for STEM projects or cosplay accessories needing durability and aesthetic appeal.

Why Choose PLA Pro Window Grey?

This

filament bridges the gap between practicality and artistry, offering a

versatile solution for projects demanding both strength and visual

elegance. Whether you’re prototyping a functional part or designing

eye-catching décor, PLA Pro Window Grey delivers consistent,

professional-quality results every time.

Unlock Creativity. Print with Precision.

Ideal for makers, designers, and innovators who refuse to compromise on quality or sustainability. Order your PLA Pro Window Grey 1kg spool today and transform your 3D visions into reality!

| Colour | Window Grey |

| Weight | 1 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

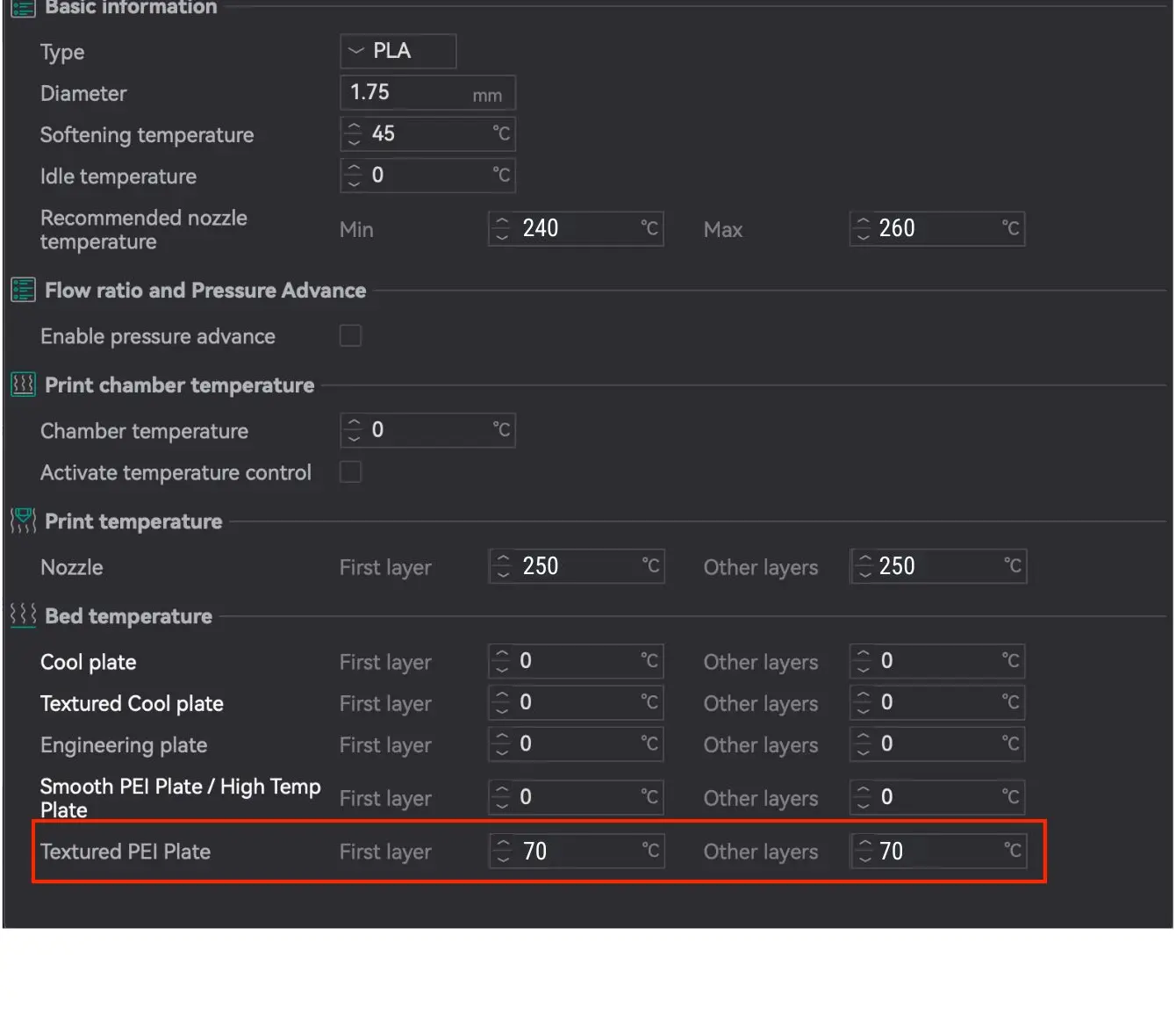

| Printing Temperature | 240-260°C |

| Bed Temperature | 60-80°C |

| Printing Speed | 40-500 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 90°C |

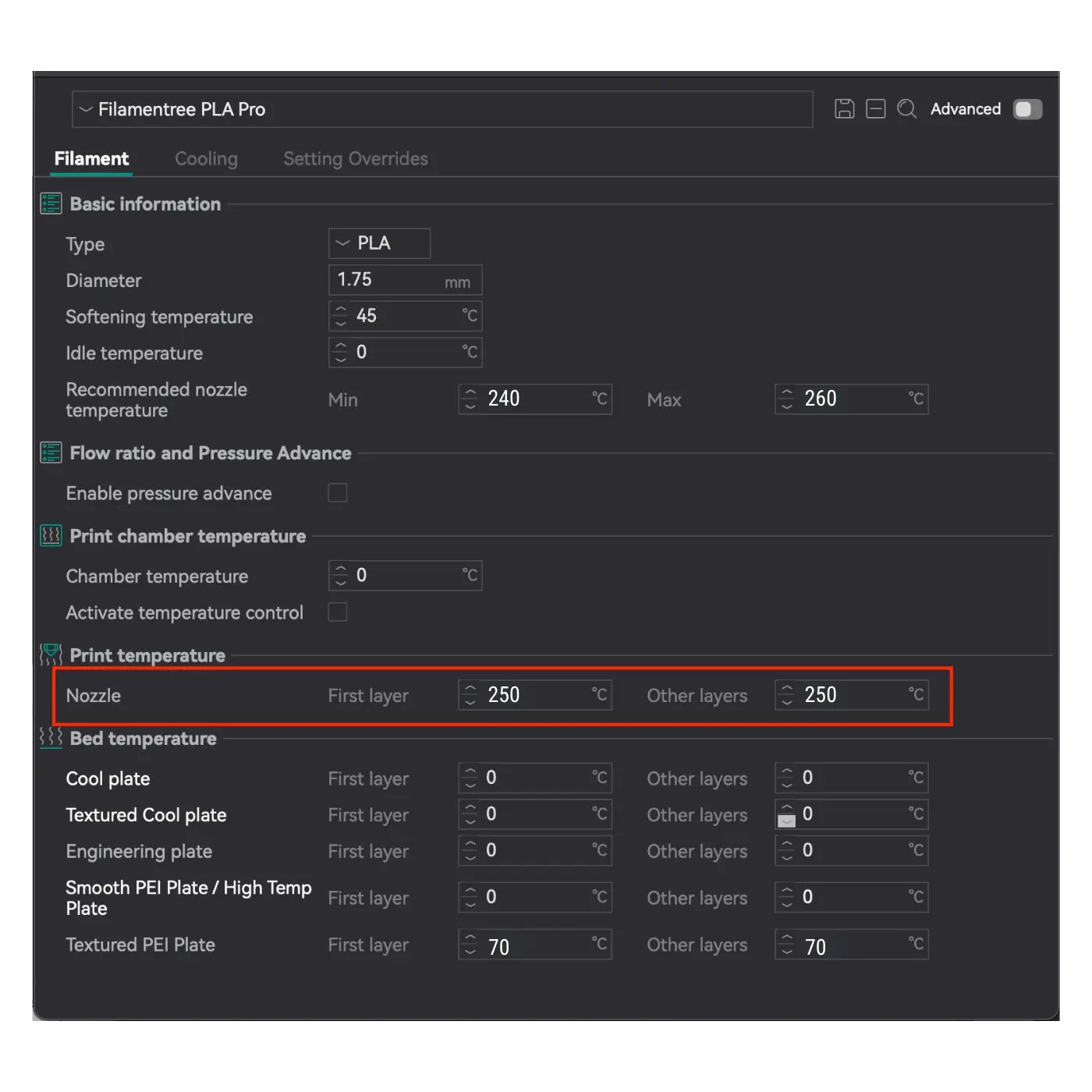

PLA Pro – Print Settings

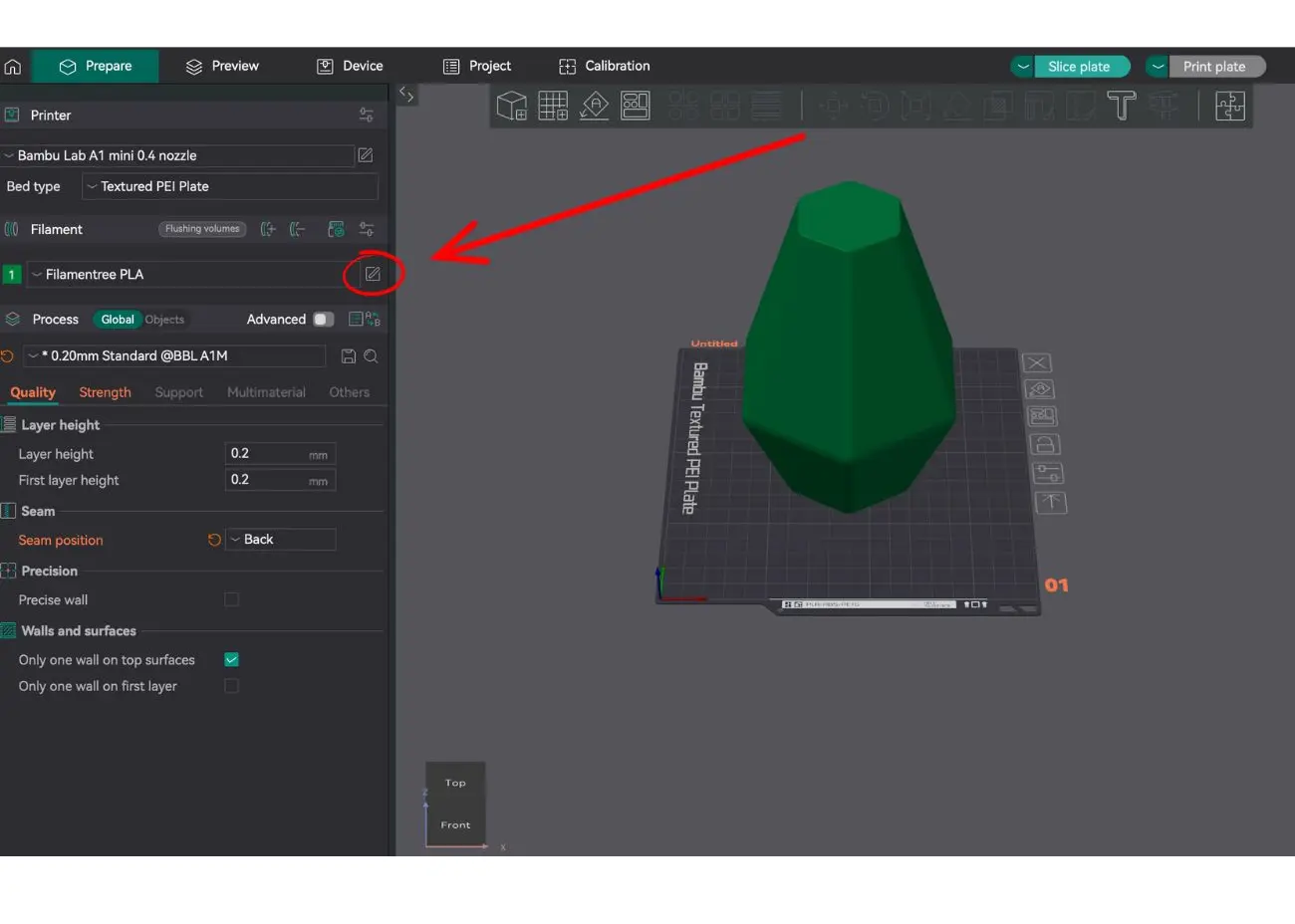

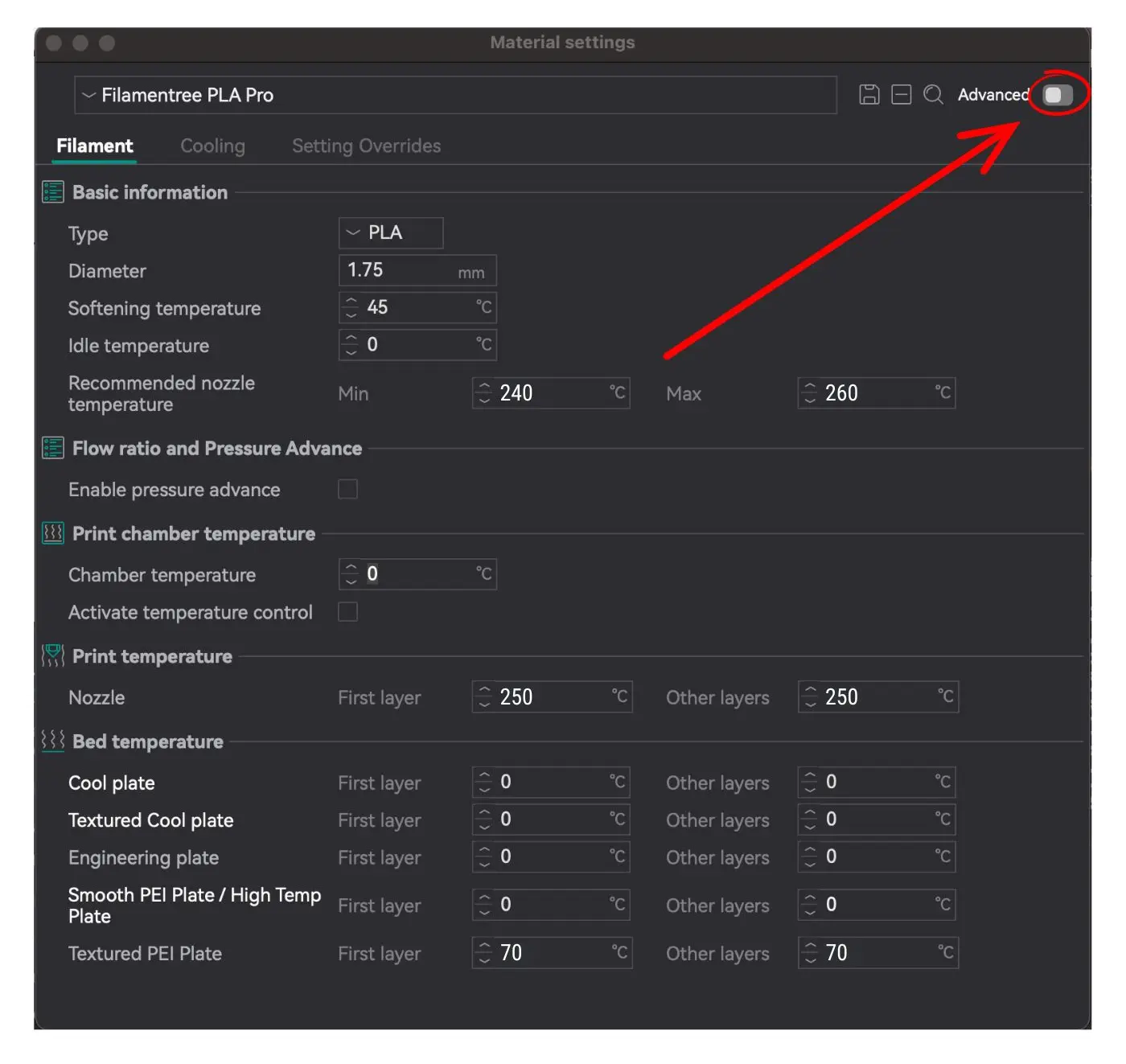

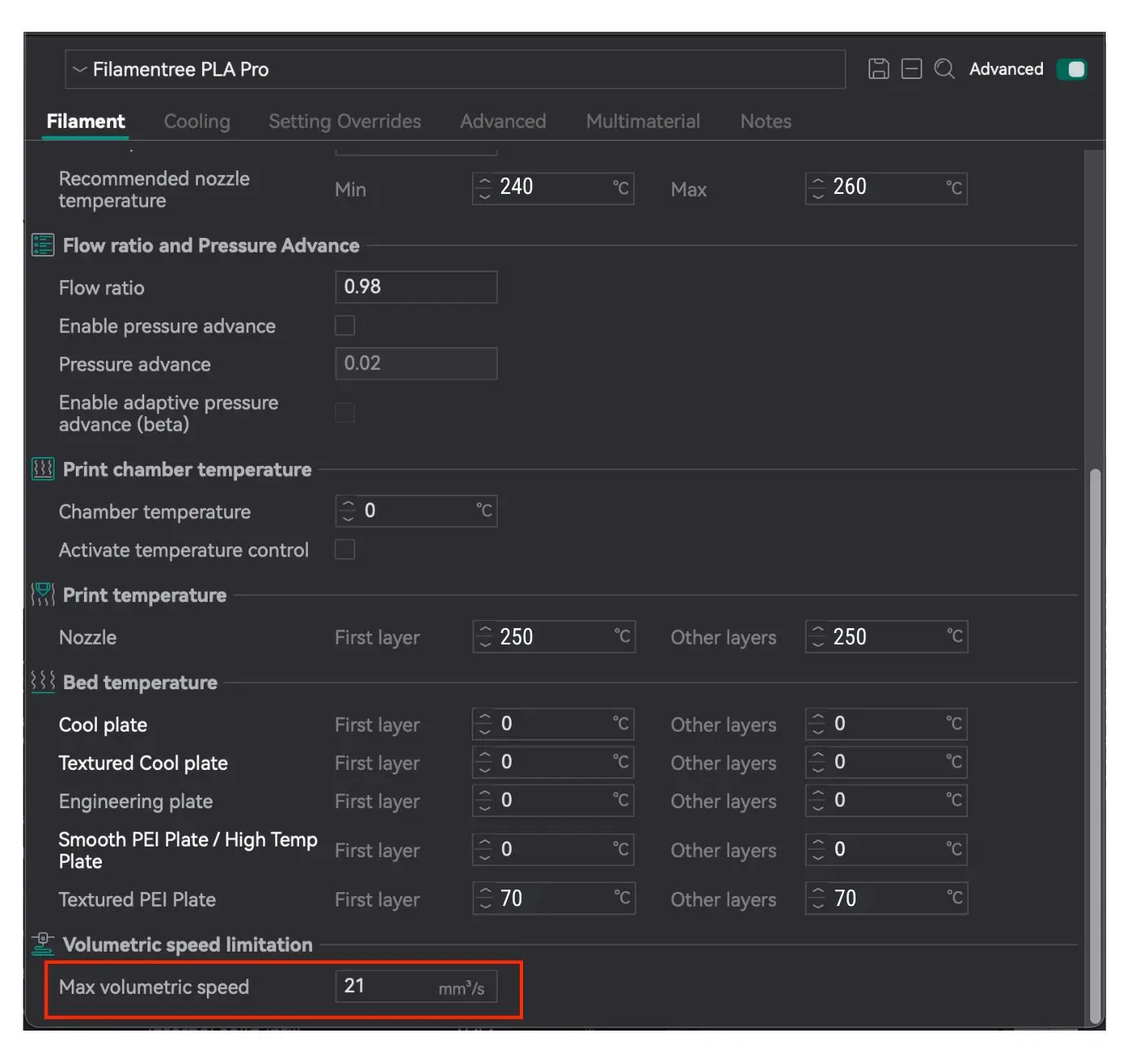

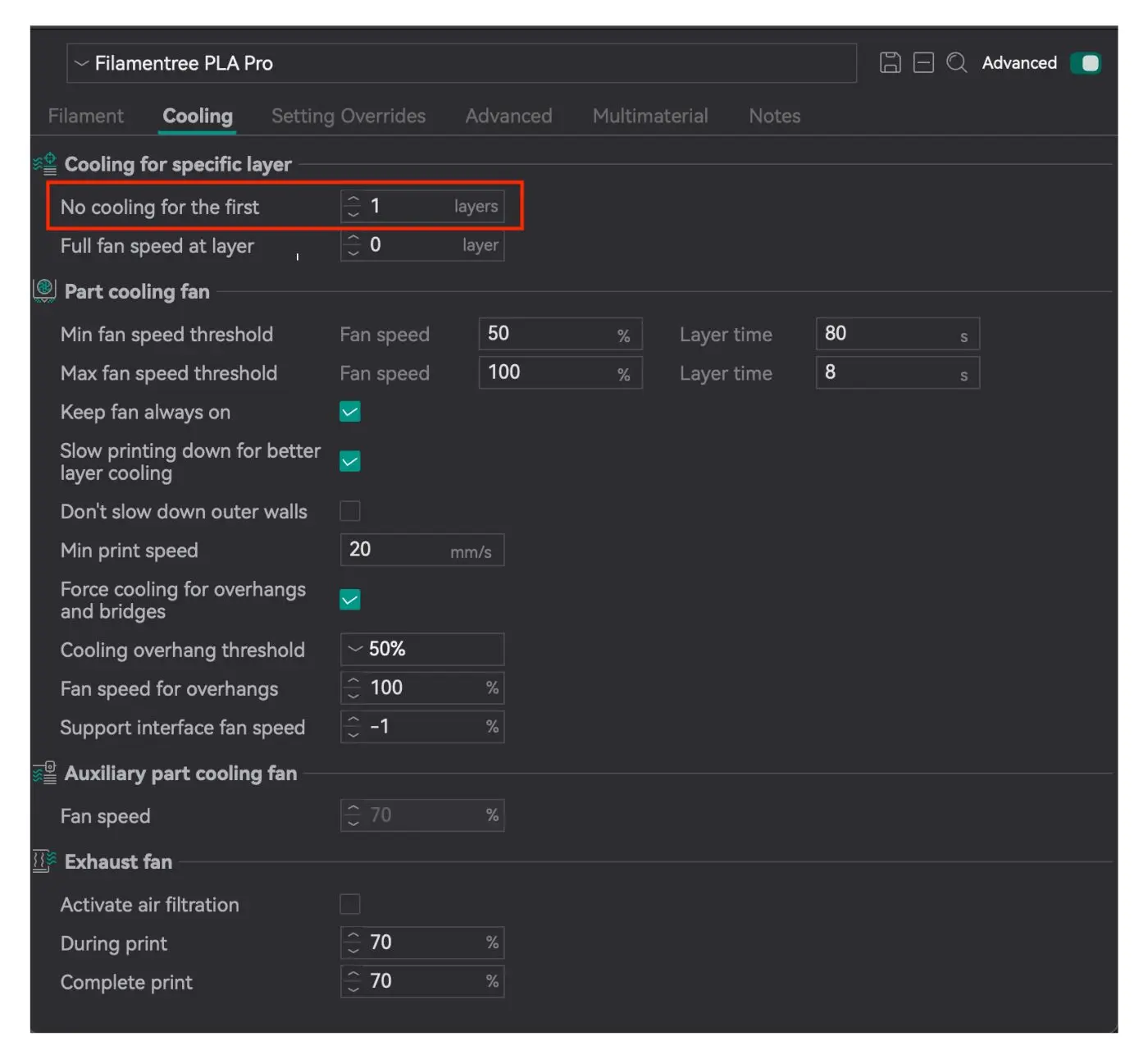

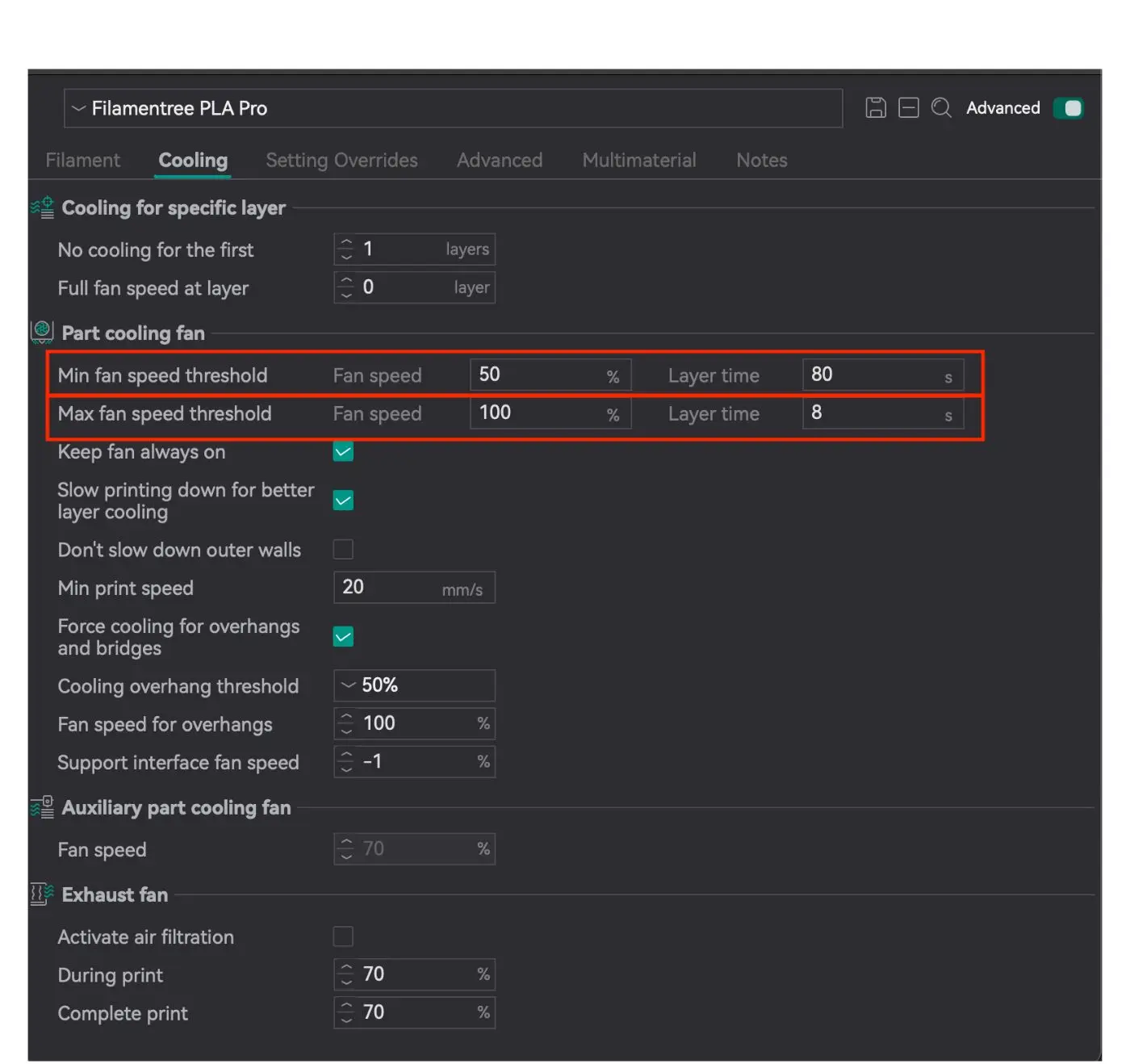

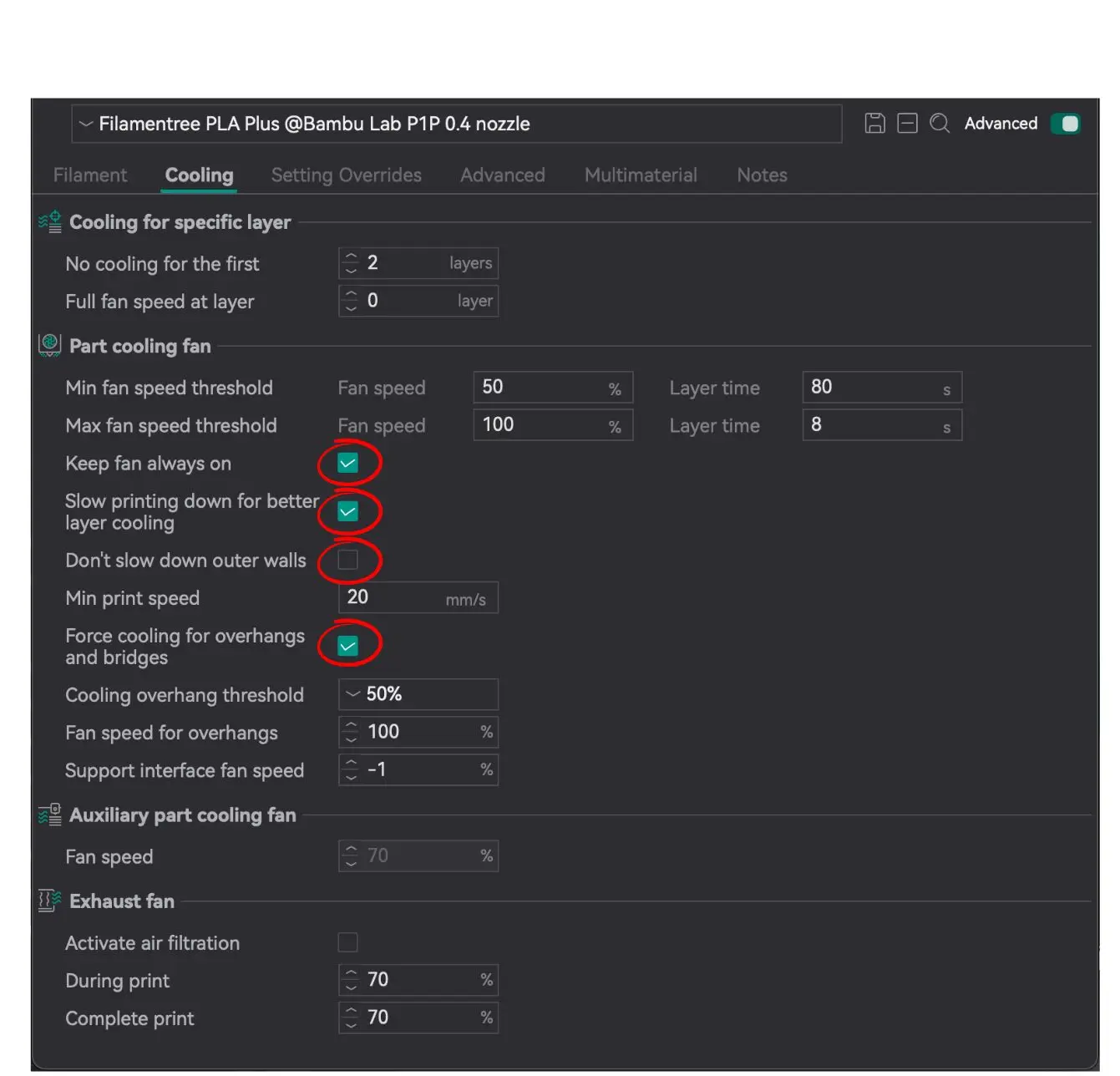

PLA Pro is an improved version of classic PLA, offering higher strength, better toughness, and increased heat resistance. This material is suitable for printing mechanically stressed parts while maintaining the ease of printing typical for PLA. To achieve optimal results, it is essential to set the printing parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

With the right slicer settings and optimized printing conditions, PLA Pro offers exceptional layer adhesion, increased impact resistance, and enhanced durability, making it a reliable choice for demanding 3D printing applications. Thanks to its improved mechanical properties, PLA Pro minimizes the risk of layer separation and ensures stable prints with sharp details and smooth surfaces. Proper cooling control, along with the correct print bed temperature, further enhances adhesion, reducing the chances of warping or model detachment.

By following these recommendations, you can achieve strong, high-quality 3D prints with PLA Pro, making it an excellent option for functional prototypes, mechanical parts, and high-detail models that require extra strength and stability.