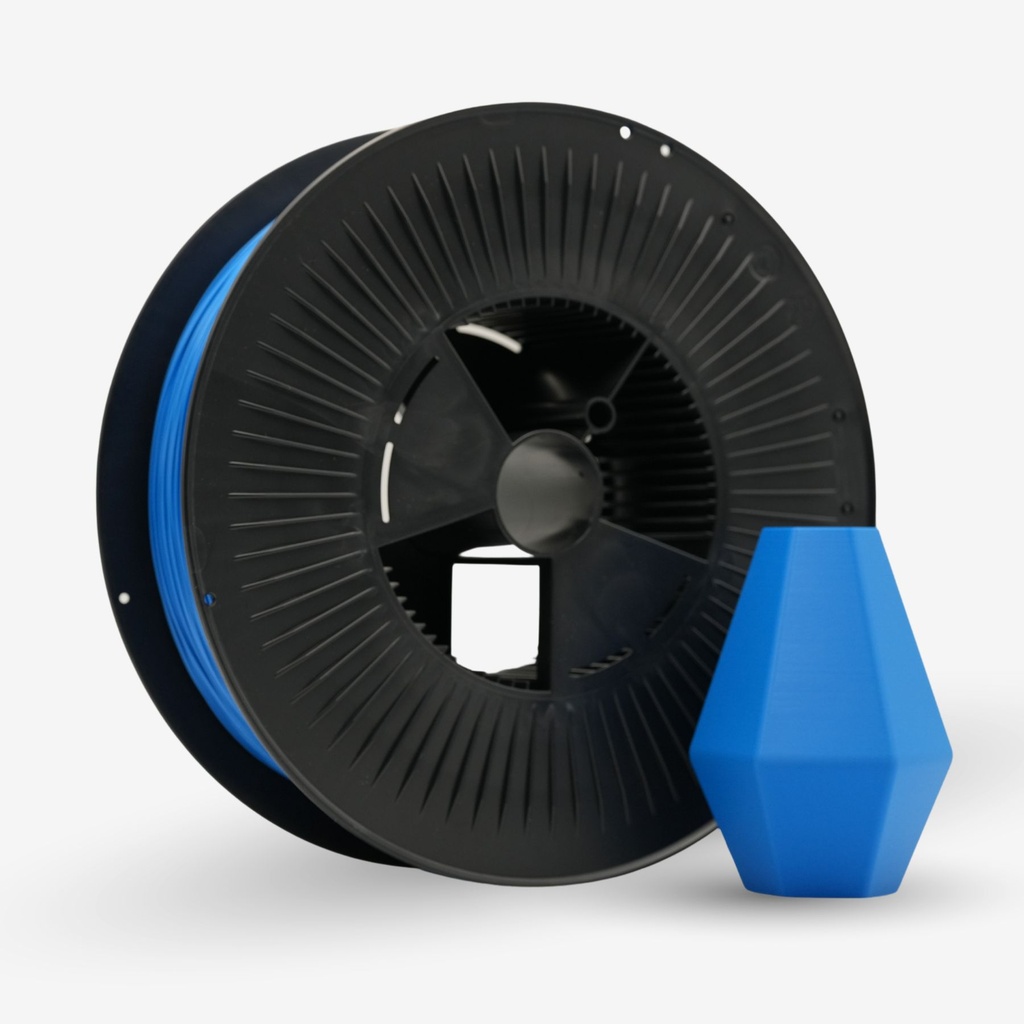

PLA Plus Blue 4kg – Premium 3D Printing Filament for Large-Scale Projects

PLA Plus Blue 4kg is a high-performance, industrial-sized filament designed for large-scale 3D printing applications. Combining the superior durability of PLA Plus with a bold, vibrant blue color, this filament offers excellent strength, smooth printing, and long-lasting performance. Ideal for professional prototyping, large functional parts, or batch production, it provides consistency and reliability for extended printing sessions without frequent spool changes.

Key Benefits

- High-Strength PLA Plus Formula: Enhanced toughness and impact resistance compared to standard PLA, making it ideal for structural components and functional parts.

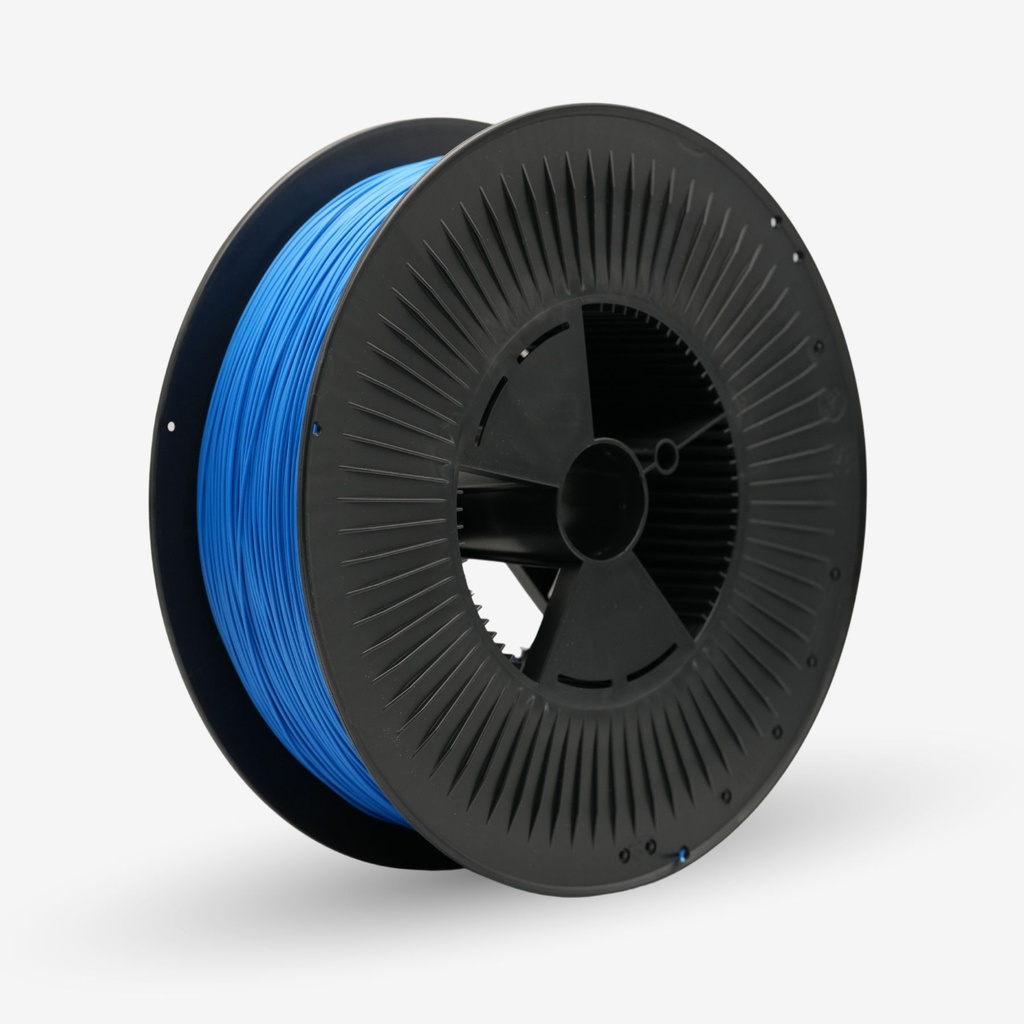

- Large 4kg Spool for Continuous Printing: Perfect for extended prints, reducing filament changes and increasing workflow efficiency.

- Bold, Vibrant Blue Color: A striking blue shade that ensures visually appealing, high-quality prints with excellent layer adhesion.

- Effortless Printing & High Compatibility: Low warping, superior bed adhesion, and seamless processing on most FDM 3D printers for hassle-free results.

- Eco-Friendly & Biodegradable: Made from renewable, non-toxic resources, supporting sustainable 3D printing practices.

Applications

- Large Prototypes & Functional Parts: Ideal for engineering-grade prototypes, casings, and industrial designs requiring structural integrity.

- Batch Production & High-Volume Printing: Streamline manufacturing with a larger spool, reducing interruptions for filament replacement.

- Architectural Models & Industrial Designs: Create detailed building prototypes, urban planning models, and mechanical structures with a clean, professional finish.

- Automotive & Aerospace Components: Print lightweight yet durable parts such as housings, enclosures, and aerodynamic components.

- Artistic & Creative Installations: Excellent for large-scale sculptures, artistic installations, and design concepts requiring a deep blue aesthetic.

Ideal For

- Engineers and manufacturers requiring large, uninterrupted prints.

- Professional prototyping and industrial-scale production.

- Artists and designers working on big projects with striking visual impact.

- Eco-conscious creators looking for sustainable yet high-performance materials.

PLA Plus Blue 4kg delivers precision, strength, and convenience for ambitious 3D printing projects. Whether for industrial applications, large-scale prototyping, or creative masterpieces, this filament ensures durability, efficiency, and vibrant color for every print.

Specifications

| Colour | Pacific Blue |

| Weight | 4 kg |

| Diameter tolerance | < 0,02 mm |

| Diameter | 1,75 mm |

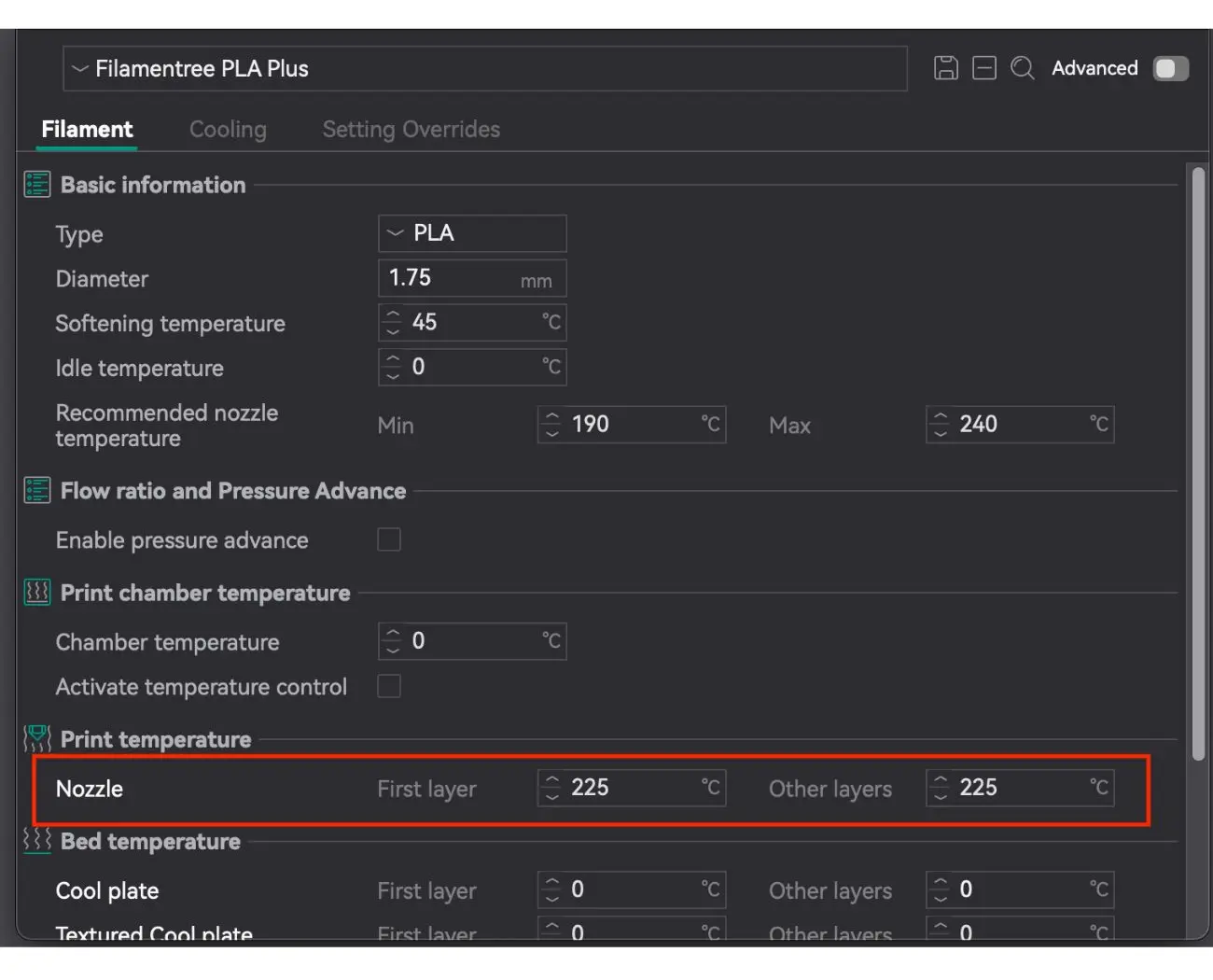

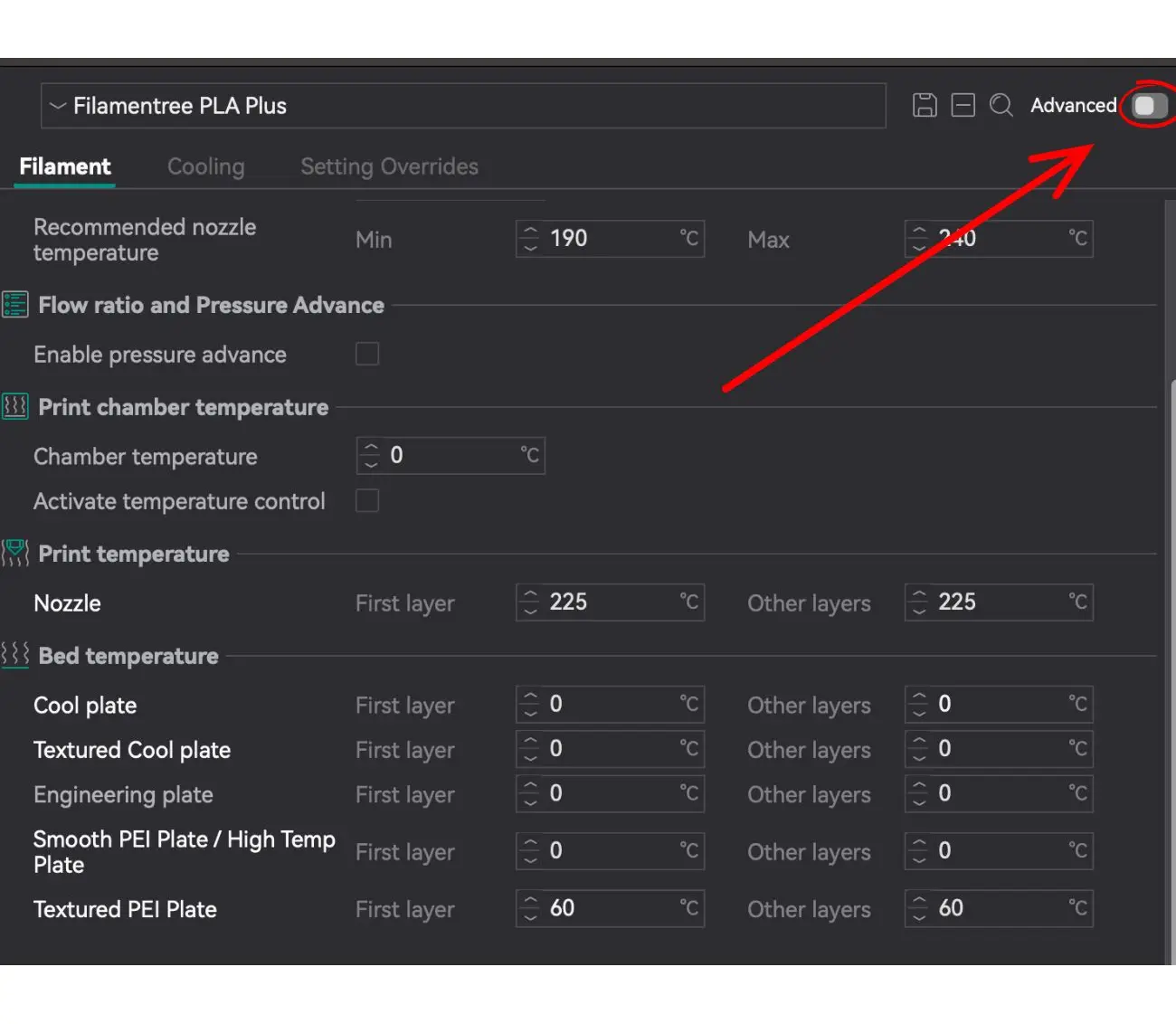

| Printing Temperature | 190–240°C |

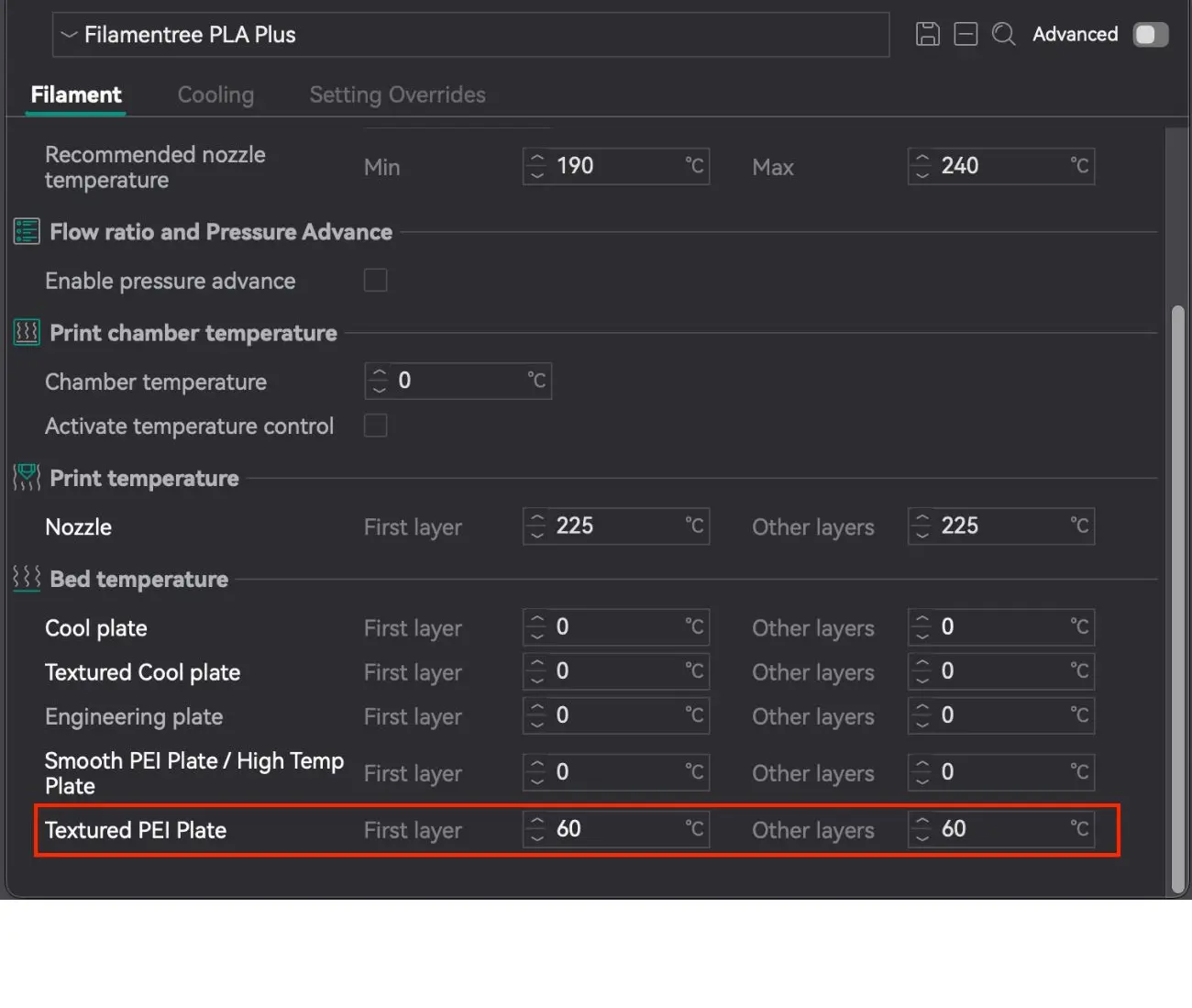

| Bed Temperature | 0–60°C (prints well without a heated bed) |

| Printing Speed | 40-300 mm/s |

| Density | 1.24 g/cm³ |

| Heat resistance | up to 50°C |

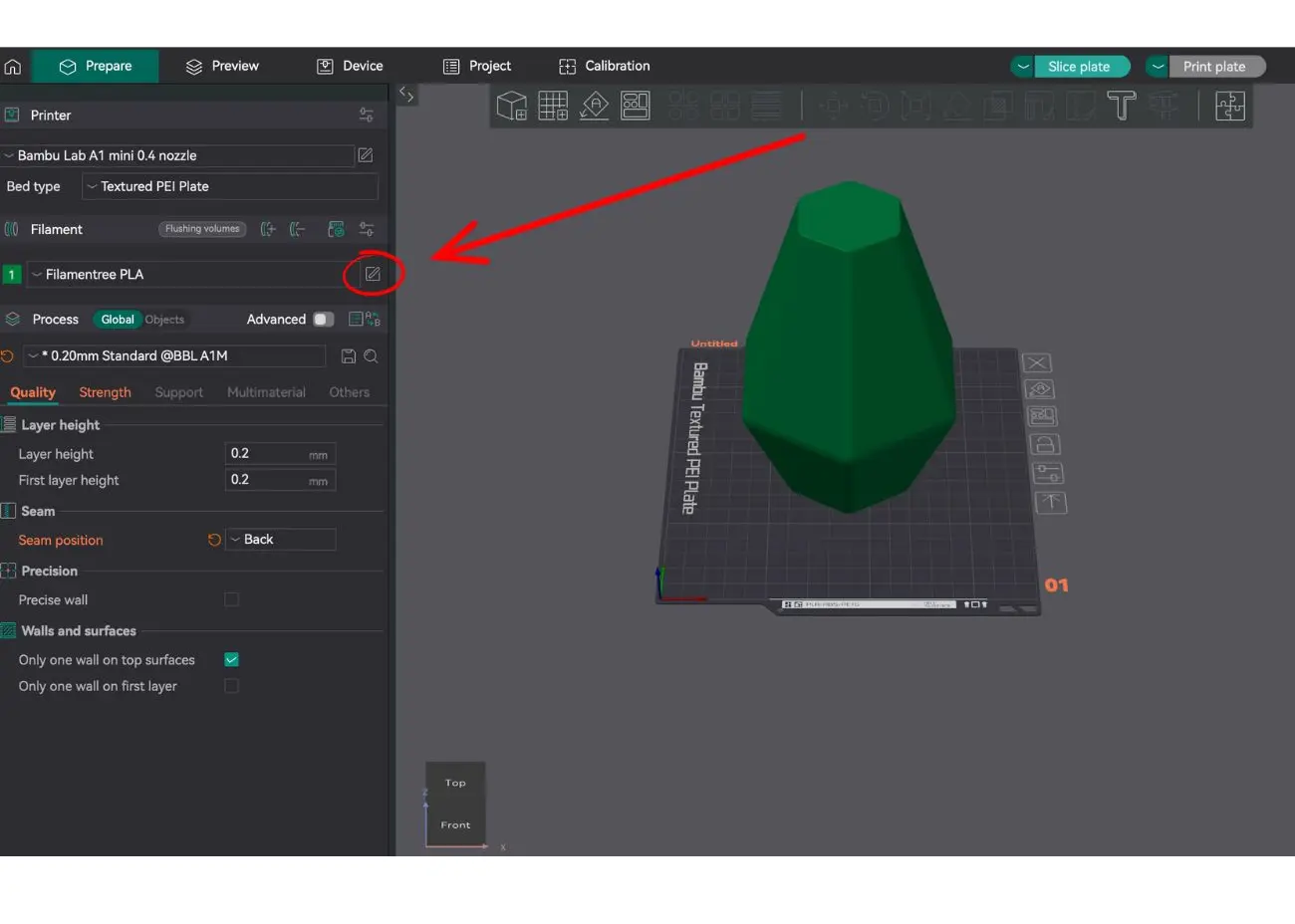

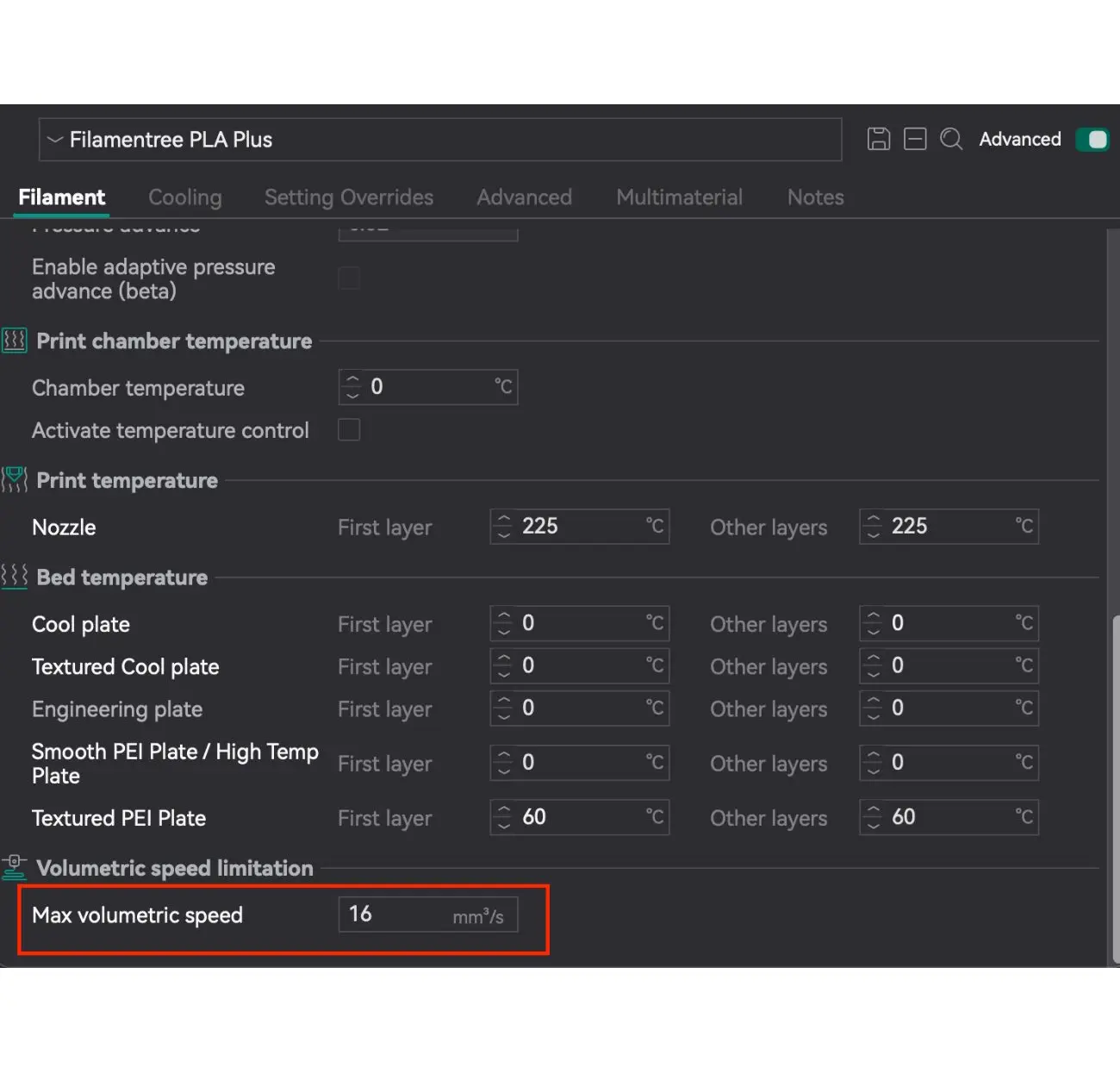

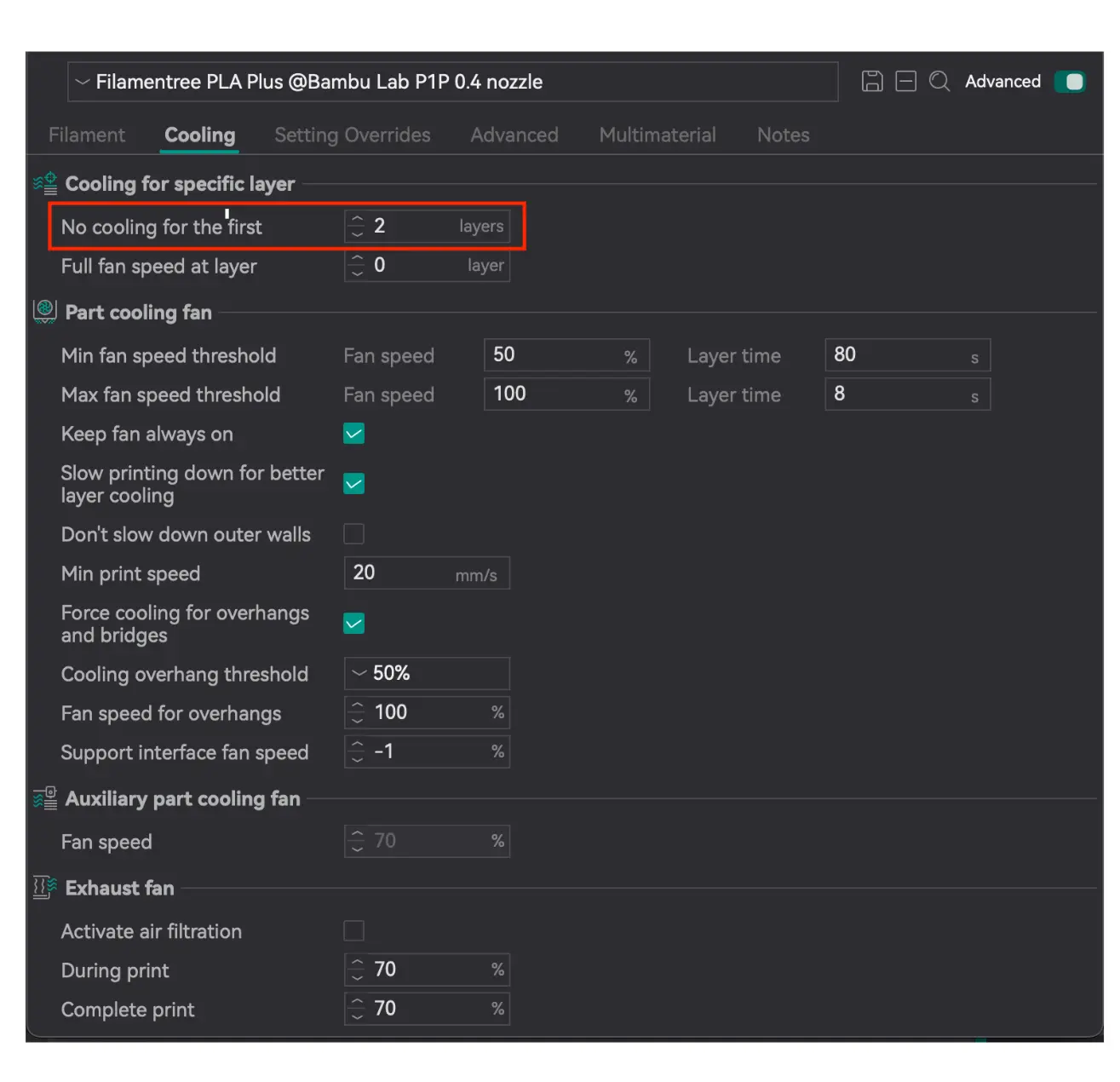

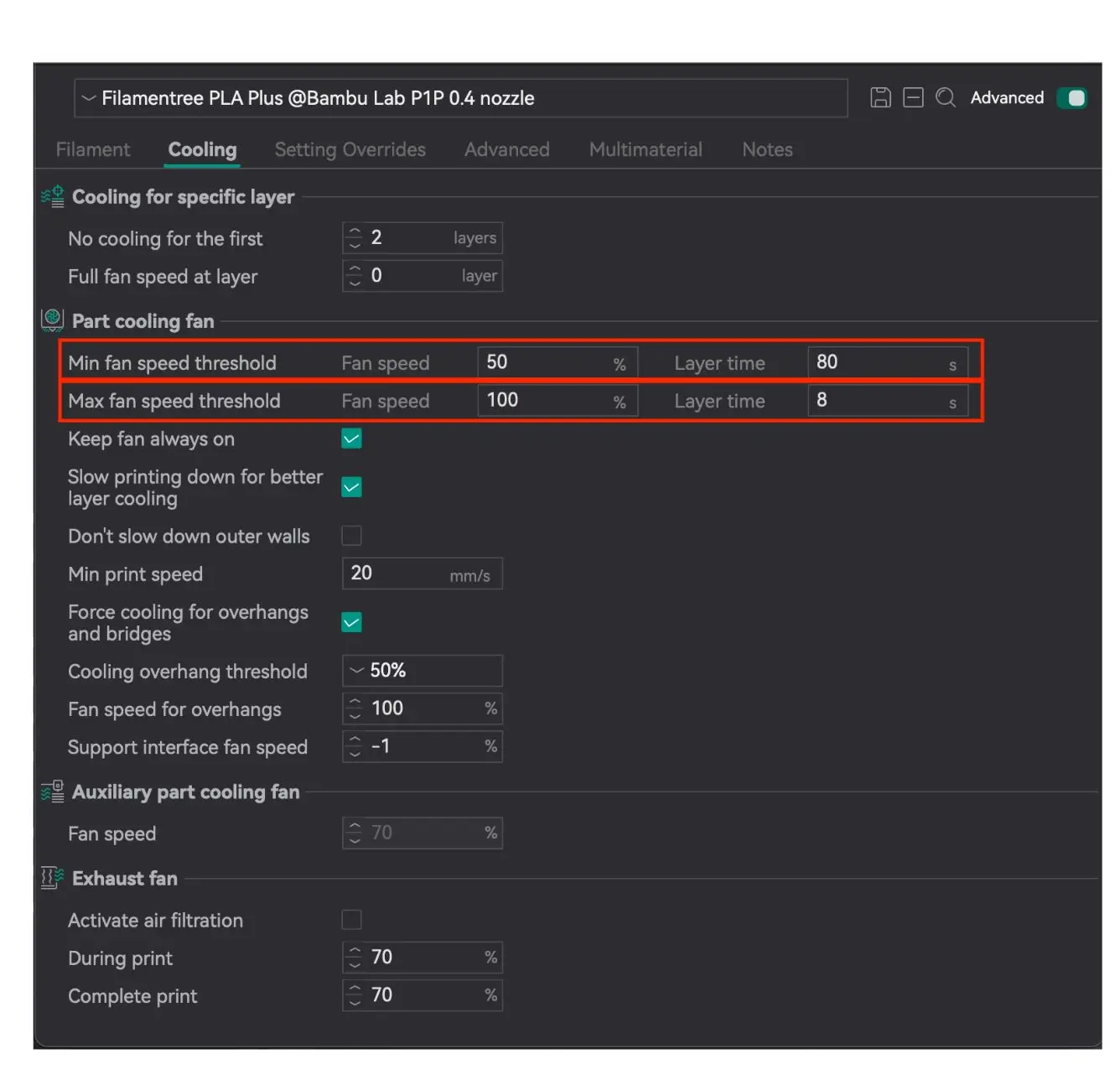

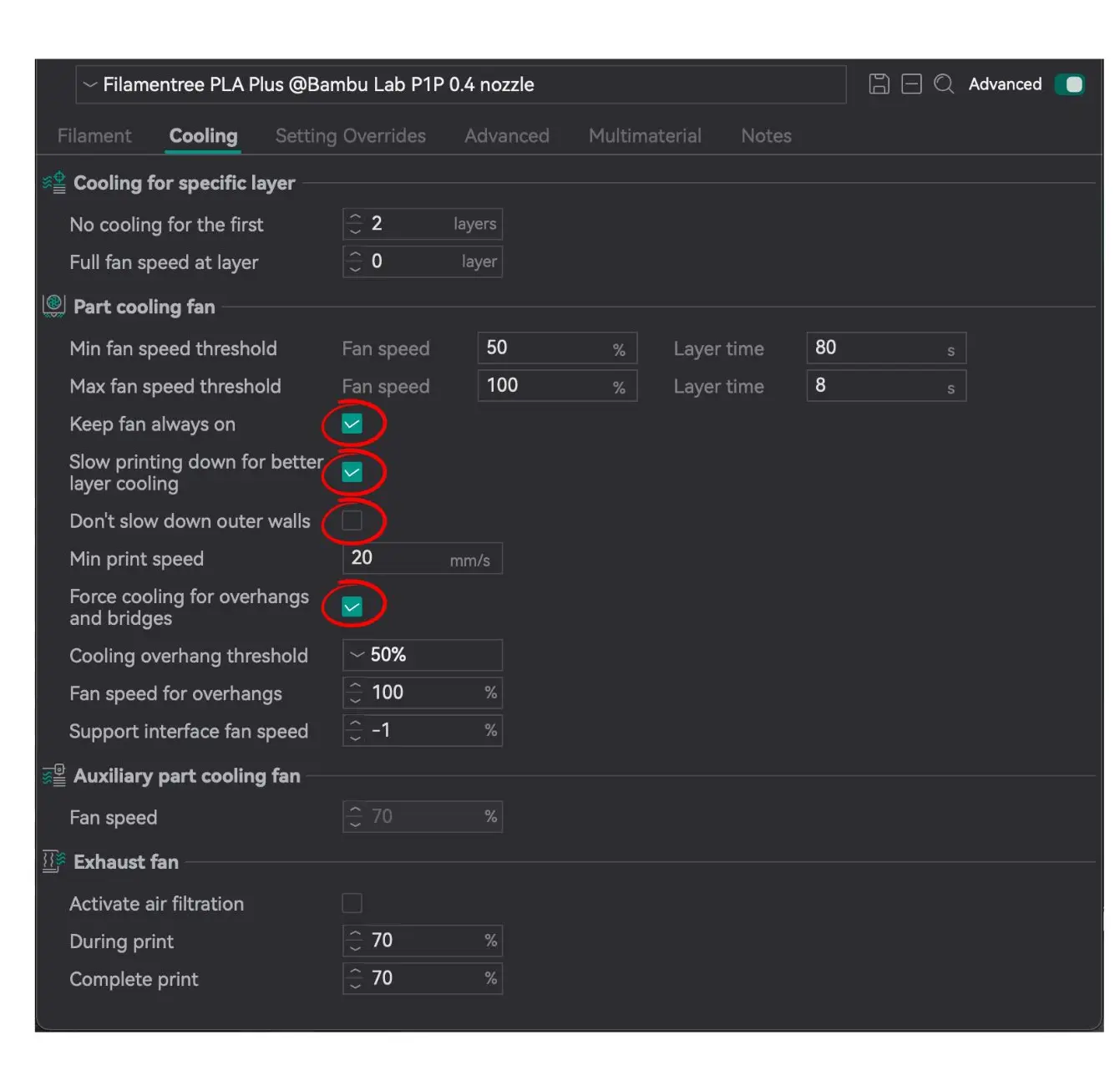

PLA Plus (PLA+) – Print Settings

PLA Plus (PLA+) is an improved version of classic PLA, offering higher strength, better flexibility, and increased durability. To achieve the best printing results, it is essential to set the parameters correctly in the slicer software. For example, in OrcaSlicer https://orca-slicer.com/ for the Bambu Lab A1 Mini printer with a 0.4 mm nozzle.

Using the correct printing parameters for PLA Plus is critically important for achieving high-quality results. PLA Plus, as an improved version of standard PLA, requires precise settings to optimize its properties. Following the recommended settings allows you to fully leverage the benefits of PLA Plus, ensuring strong, aesthetically appealing, and durable prints.